Greg Hrinya, Associate Editor05.17.19

On the heels of a record-breaking Xeikon Cafe Europe, Xeikon brought its event to North America for the third time–welcoming over 220 guests to Itasca, IL, USA from May 14-16, 2019. Xeikon Cafe North America featured educational sessions, industry updates, customer testimonials, a trip to the company’s Innovation Center, and a well-attended Partner Fair.

According to Benoit Chatelard, Xeikon CEO, the event is designed to increase the company’s global presence. Xeikon has seen 15% growth globally, as well as 40% in the US marketplace. Xeikon Cafe North America came a little over a month after the European addition, which saw 1,000 attendees arrive at Xeikon’s headquarters in Lier, Belgium.

During a press conference, Chatelard also announced that Xeikon would be opening an Innovation Center in Shanghai, intended to grow the company’s reach in China. More information will be released closer to Labelexpo Europe, which will see Xeikon continue to expand with parent group Flint Group.

“Our strategy is paying off, that’s for sure,” Chatelard said. “It has been a big transformation since I joined as CEO. We’re getting bigger and better, and it’s up to us to demonstrate how we’re developing.

“Two years ago when taking the job, I made the strategic decision to really focus on North America. The solutions and services have been a really good fit for this market.”

In addition to Xeikon’s digital printing presses, highlighted by the recently launched Panther, the company showcased an end-to-end workflow, including the X-800 DFE. The company also announced new leadership hires, designed to continue global growth. Klaus Nielsen, recently appointed as director of Xeikon Asia Pacific, was introduced to the North American market at the event. In his new role, Nielsen will oversee Xeikon’s ongoing growth in the APAC region (Greater China, Japan, Australia, and New Zealand).

Chatelard added that the company has also invested in enhanced workflow solutions, bringing a cohesive approach to MIS and the chain of automation. The X-800 DFE has been designed to reduces costs and waste while lowering setup times on press and finishing. According to Xeikon, running 164 fpm can achieve the same output as 264 fpm by optimizing data before sending it to the press.

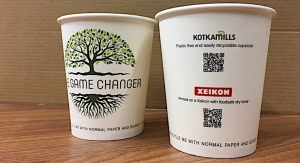

With Panther technology serving as Xeikon’s newest development, Chatelard noted that the company’s R&D investments are nearly 50/50 with inkjet and dry toner. Showcasing the “Power of Dry Toner,” Xeikon detailed a new generation of products that fits under Nestle Guideline compliance. Water-based inks have been developed for food-safe options.

“We have put a lot of resources into dry toner and UV inkjet,” explained Jeroen Van Bauwel, director of product management at Xeikon. “It has resulted in new functionality, first with the High Capacity Panther. It’s based on feedback we’ve gotten from our customers and their desire for reduced substrate costs. We have an answer and we can raise OEE (overall equipment efficiency) by 20%, and it’s available now.”

Panther technology has proven reliable for labels in various markets, including health and beauty, durable, and chemical labeling, the company said.

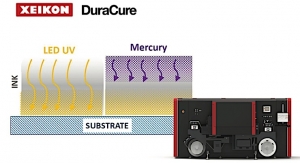

Highlighting the entire workflow, Xeikon also detailed the launch of Automated Ink Optimization and Panther DuraCure technology. Automated Ink Optimization has seen benefits in health and beauty and premium beer labels while printing on clear substrates. The technology varies ink layer thickness across the web, allowing for longer runs. On the ThermoFlexX side, Scott Campbell said the new Woodpecker Nano raises the bar in flexo quality without compromising productivity. Woodpecker Nano does not require a special RIP, as its built into the machine.

“We have developed a key portfolio in how we want to address specific label markets,” said Filip Weymans, VP of marketing at Xeikon. “If we look back over what we’ve done since 2008, we’ve developed unique applications, such as heat transfer, wraparound labels, and now flexible packaging. Dry toner allows us to expand our application range.

“Inkjet, alongside our dry toner, can address different end use markets. People questioned us when we started talking about that strategy, and we have a customer in Italy that, in the label market, this differentiation has made the customer stronger,” added Weymans.

Not only did Xeikon North America showcase the company’s capabilities to prospective customers, Dave Wilkins, VP of sales for Xeikon North America, cited the importance of having existing customers present to speak to their successes with Xeikon technology. Converters like CS Labels, AccuLabel, Lake Graphics and more were on-hand as part of panel discussions detailing the technology.

“It’s exciting to talk about existing customers who continue to keep coming back to Xeikon,” stated Wilkins. Wilkins added that he wanted attendees to “learn how to innovate and thrive in a fast-paced business marketplace by networking, keeping an open mind, asking questions, and thinking outside the box.”

As part of the Partner Fair, over 60 representatives from 34 partners were available to talk about their latest product innovations. Joel Ulrich, roll product manager at Spinnaker Coating, said that the Partner Fair allowed his company to highlight how its substrates can work with Xeikon printing technology.

With Xeikon now offering multiple digital printing technologies, UPM Raflatac’s Kirit Naik explained how his company has made it easier for customers to select the appropriate substrates based on their applications.

Additionally, representatives were on-hand from AB Graphic, acpo, Avery Dennison, Kocher + Beck, FLEXcon, Label Traxx, Prati, and more. Plus, FLAG (Flexo Label Advantage Group) was able to add another member during the Partner Fair, showcasing the beneficial networking opportunities at Xeikon Cafe North America.

According to Benoit Chatelard, Xeikon CEO, the event is designed to increase the company’s global presence. Xeikon has seen 15% growth globally, as well as 40% in the US marketplace. Xeikon Cafe North America came a little over a month after the European addition, which saw 1,000 attendees arrive at Xeikon’s headquarters in Lier, Belgium.

During a press conference, Chatelard also announced that Xeikon would be opening an Innovation Center in Shanghai, intended to grow the company’s reach in China. More information will be released closer to Labelexpo Europe, which will see Xeikon continue to expand with parent group Flint Group.

“Our strategy is paying off, that’s for sure,” Chatelard said. “It has been a big transformation since I joined as CEO. We’re getting bigger and better, and it’s up to us to demonstrate how we’re developing.

“Two years ago when taking the job, I made the strategic decision to really focus on North America. The solutions and services have been a really good fit for this market.”

In addition to Xeikon’s digital printing presses, highlighted by the recently launched Panther, the company showcased an end-to-end workflow, including the X-800 DFE. The company also announced new leadership hires, designed to continue global growth. Klaus Nielsen, recently appointed as director of Xeikon Asia Pacific, was introduced to the North American market at the event. In his new role, Nielsen will oversee Xeikon’s ongoing growth in the APAC region (Greater China, Japan, Australia, and New Zealand).

Chatelard added that the company has also invested in enhanced workflow solutions, bringing a cohesive approach to MIS and the chain of automation. The X-800 DFE has been designed to reduces costs and waste while lowering setup times on press and finishing. According to Xeikon, running 164 fpm can achieve the same output as 264 fpm by optimizing data before sending it to the press.

With Panther technology serving as Xeikon’s newest development, Chatelard noted that the company’s R&D investments are nearly 50/50 with inkjet and dry toner. Showcasing the “Power of Dry Toner,” Xeikon detailed a new generation of products that fits under Nestle Guideline compliance. Water-based inks have been developed for food-safe options.

“We have put a lot of resources into dry toner and UV inkjet,” explained Jeroen Van Bauwel, director of product management at Xeikon. “It has resulted in new functionality, first with the High Capacity Panther. It’s based on feedback we’ve gotten from our customers and their desire for reduced substrate costs. We have an answer and we can raise OEE (overall equipment efficiency) by 20%, and it’s available now.”

Panther technology has proven reliable for labels in various markets, including health and beauty, durable, and chemical labeling, the company said.

Highlighting the entire workflow, Xeikon also detailed the launch of Automated Ink Optimization and Panther DuraCure technology. Automated Ink Optimization has seen benefits in health and beauty and premium beer labels while printing on clear substrates. The technology varies ink layer thickness across the web, allowing for longer runs. On the ThermoFlexX side, Scott Campbell said the new Woodpecker Nano raises the bar in flexo quality without compromising productivity. Woodpecker Nano does not require a special RIP, as its built into the machine.

“We have developed a key portfolio in how we want to address specific label markets,” said Filip Weymans, VP of marketing at Xeikon. “If we look back over what we’ve done since 2008, we’ve developed unique applications, such as heat transfer, wraparound labels, and now flexible packaging. Dry toner allows us to expand our application range.

“Inkjet, alongside our dry toner, can address different end use markets. People questioned us when we started talking about that strategy, and we have a customer in Italy that, in the label market, this differentiation has made the customer stronger,” added Weymans.

Not only did Xeikon North America showcase the company’s capabilities to prospective customers, Dave Wilkins, VP of sales for Xeikon North America, cited the importance of having existing customers present to speak to their successes with Xeikon technology. Converters like CS Labels, AccuLabel, Lake Graphics and more were on-hand as part of panel discussions detailing the technology.

“It’s exciting to talk about existing customers who continue to keep coming back to Xeikon,” stated Wilkins. Wilkins added that he wanted attendees to “learn how to innovate and thrive in a fast-paced business marketplace by networking, keeping an open mind, asking questions, and thinking outside the box.”

As part of the Partner Fair, over 60 representatives from 34 partners were available to talk about their latest product innovations. Joel Ulrich, roll product manager at Spinnaker Coating, said that the Partner Fair allowed his company to highlight how its substrates can work with Xeikon printing technology.

With Xeikon now offering multiple digital printing technologies, UPM Raflatac’s Kirit Naik explained how his company has made it easier for customers to select the appropriate substrates based on their applications.

Additionally, representatives were on-hand from AB Graphic, acpo, Avery Dennison, Kocher + Beck, FLEXcon, Label Traxx, Prati, and more. Plus, FLAG (Flexo Label Advantage Group) was able to add another member during the Partner Fair, showcasing the beneficial networking opportunities at Xeikon Cafe North America.