Greg Hrinya, Associate Editor01.20.17

With a wide range of substrates permeating the label and narrow web market, rotary diecutting has become as important as ever. Whether utilizing flexible or solid dies, tooling suppliers play a critical role in the finished label.

The industry has seen a considerable shift toward flexible dies in recent years. As Andre Gysbers, marketing director at Wink, explains, flexible dies are the first choice for many label and narrow web applications. Production and delivery have become much timelier, and converters can diecut unique shapes and angles. Special surface treatment products have made flexible dies far more durable, as well, which alleviates some of those concerns when compared to solid tooling.

“With increased speeds, automation and shorter downtimes, there are general trends toward diversification, specialties and smaller runs, as well as increased quality demands from end consumers and brand owners,” says Gysbers. “This has had a strong influence on diecutting technology. The general quality level has been increased, and many refinements/surface treatments have been established to optimize performance for various applications.”

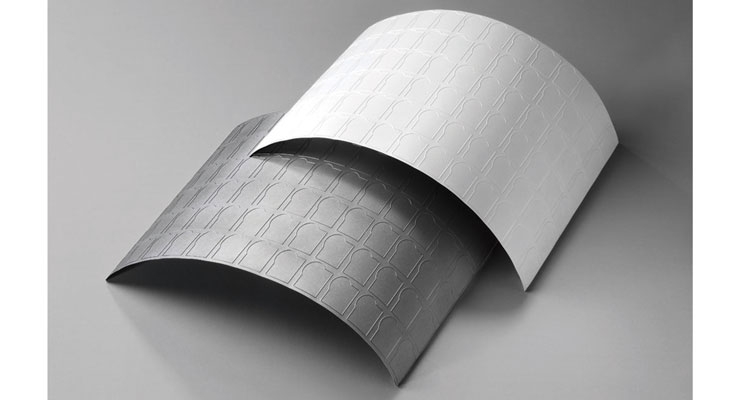

Wink offers a complete range of rotary diecutting tools and equipment. The company features SuperCut flexible dies with various finishing options for many label and narrow web applications. In addition, Wink offers a complete range of rotary cylinders, including solid dies, magnetic, printing, sheeting and anvil cylinders, and also the GapControl adjustable anvil system, diecutting stations and pressure gauges. “Especially here at Wink, we have invested a lot in machinery, technology and personnel so that we were able to reduce die tolerances to a minimum, while at the same time producing high-precision and consistent quality very efficiently,” explains Gysbers.

Kocher + Beck sees advances in tooling, as well as with ancillary equipment used in the rotary diecutting process. “Within the production of flexible dies, all blade profiles are fully CNC machine sharpened, with height tolerances being held within microns as standard,” explains David Morris, president of Kocher + Beck USA. “We also offer a range of coatings for additional applications, as well as laser hardening to give increased die life.” Kocher + Beck also offers label converters the GapMaster adjustable anvil system, which allows extremely fine adjustment of the depth of cut while the press is running.

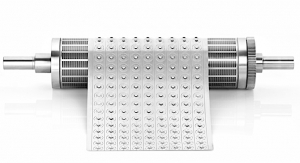

Flexible dies are suited to handle pressure sensitive materials, as the industry shifts more toward synthetic face materials and thinner liners. Kocher + Beck has seen a number of its products work seamlessly for rotary diecutting, including its high-precision flexible dies and magnetic cylinders. In addition to the GapMaster system, customized cutting stations and solid rotary cutters earmarked for specialized applications are also applicable.

Tooling suppliers have answered the demands for process improvement, much like other facets of the label and packaging industry. Brand owners, graphic designers and retailers are facing the challenge of reducing resource consumption and waste. Meanwhile, converters are using thinner materials and need finishing tools that provide tighter tolerances and last longer. “We, as a tooling supplier, have to reinvent ourselves to keep up with the always changing market requirements,” explains Ulrich Kretzschmar, global product and business development, RotoMetrics. “As an example, plate height tolerances of a rotary cutting tool converting a thin PET liner for beverage labels have to be five times tighter than one for a paper liner, which was the standard not too long ago.”

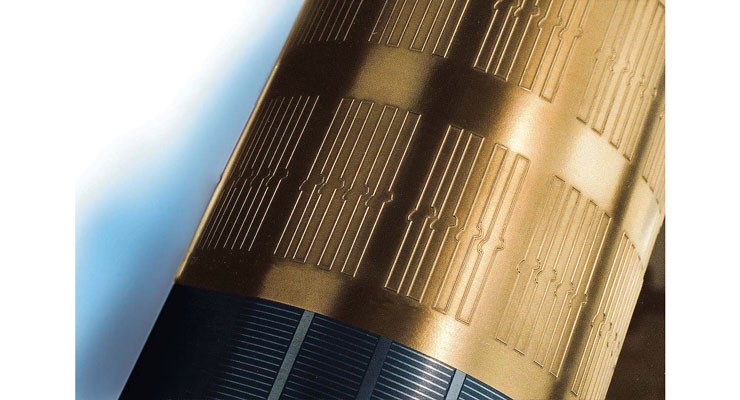

RotoMetrics manufactures a wide range of rotary tooling options, including solid and flexible dies, magnetic cylinders, anvils, print cylinders and sleeves, plus accessories. “Our customers need precision tools, and they need them fast,” adds Kretzschmar. “We have optimized the manufacturing process to allow us to finish flexible dies in several hours – instead of days. A fair share of the more than 1,100 flex dies we produce daily ship the same day from our manufacturing facilities on five continents. Improved and optimized blade geometries, in combination with dedicated finishing processes, opened the doors to new opportunities utilizing flexible die technology outside the tag and label markets.”

There is a financial benefit to flexible dies, too. According to Markus Marfurt, president and CEO of Electro Optic, flexible die systems cost roughly 25% less than traditional diecutting tools. “Flexible die tools from Electro Optic work as good or better than solid tools, consequently resulting in the expected cost reduction when using them,” explains Marfurt. “Changing market demands, such as digital printing, require fast, reliable and cost effective diecutting tool solutions.”

Electro Optic specializes in the manufacturing of flexible dies. The company’s Gold Line Special Flexible Die has been designed to address the die strike consistency of the thin gauge liner materials. These flexible dies also meet critical cutting requirements for challenging facestocks like MDO (machine direction orientation). Electro Optic’s DURA coating provides a greater longevity for highly abrasive substrates, such as thermal transfer, or higher volume jobs like those seen on thinner gauges. Also, the DURA coating has been designed to improve die life significantly. The product may also include extra hardening and coating processes.

Technological enhancements have also allowed converters to generate tighter tolerances. “The move to fully servo-driven diecutting systems has given converters the ability to have computer controlled registration and allows for extremely tight tolerance cutting,” explains Dave Grenwis, marketing manager at Delta ModTech. “Along with constant advancements in software programing, the manufacturing of rotary dies, gearing and sensors continues to allow for increased speed and consistent cuts.”

Delta ModTech provides rotary diecuting capabilities for all of its machine offerings. The Crusader Converter is an entry-level diecutting platform for general web converting applications, and the company finds that it is popular for contract converters and R&D environments. Additionally, the Spectrum Finishing System is a digital print finishing system, which Delta ModTech describes as its most flexible solution for diecutting digitally printed webs, allowing for both semi-rotary and full rotary cutting. “We also build custom turn-key diecutting systems using the same modular platform found on all of our machines,” says Grenwis. “These systems range from advanced label finishing systems to transdermal patch manufacturing machines to fully integrated IVD manufacturing lines.”

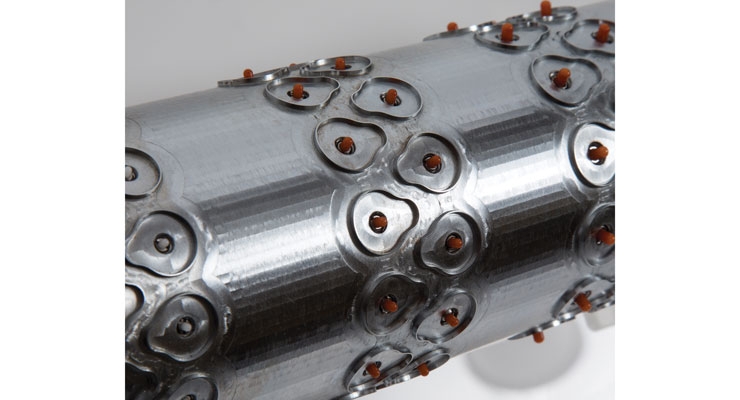

Wilson has nearly 40 years of experience in the medical, automotive and label industries. Priding itself on the knowledge and technical support it can provide to its clients, the company offers everything from machine-sharpened rotary dies to magnetic and print cylinders. Wilson’s cylinders are manufactured with automated CNC machinery to assure accuracy and consistency, as well as containing ceramic and rare earth magnets. The machine-sharpened dies were created for abrasive, tight tolerances and long-run applications.

“Machine sharpening has been the key to technology growth, allowing for tighter tolerance, consistency and angles required for today’s thin films,” explains Wade Fouts, VP at Wilson Manufacturing. “We supply the finishing accessories including, but not limited to, magnetic cylinders, solid, flexible, anvil rolls, and print cylinders.”

There is still a need for solid tooling, though. Solid tools are still relied upon for high-caliper material, as the longer blade height can accommodate thicker materials. Marfurt adds that solid tools may outperform alternative diecutting options in steel-to-steel applications, especially when dealing with long fiber content, such as fabrics and certain films.

“Diecutting with solid tooling is still the best choice for long runs,” says Jason Newville, design engineer at Delta ModTech. “Full rotary cutting allows for the highest speeds available. However, semi-rotary cutting is catching up. Solid tooling can also last longer before its needs sharpening.”

Gysbers states that companies will also opt for solid tooling – including air eject and pin eject systems – when there is a need to remove waste from the web and/or tooling.

Today flexible dies are seeing increased technological capabilities to handle materials that were once not feasible. “Although we continue to see more areas of the converting industry moving to flexible dies, there will always be those where a solid rotary tool is better suited,” says Morris. “This, however, is in the more specialized applications where thicker stocks are being used, although even here we are seeing a move – where possible – to flexible tooling.”

Navigating substrates

Substrates can pose a challenge in rotary diecutting. In addition to meeting faster delivery times, converters must navigate substrates that – while appealing on the shelf – are difficult to finish.

“Substrates always have and always will affect the rotary cutting process,” explains Wilson’s Fouts. “This is why it is important your supplier is knowledgeable in regards to the characteristics of all substrates to assist you in choosing the right tooling.”

“Challenging substrates, such as MDOs, require very sharp cutting properties to offset the vertical and horizontal difference on strength built into the substrate,” says Electro Optic’s Marfurt. “Highly abrasive contents, such as encounters with thermal transfer materials or certain inks, will reduce the tool life significantly.”

According to Wink’s Gysbers, the main challenges in rotary diecutting center on the substrates. Die strikes on the liner need to be avoided, since they essentially damage the liner. By avoiding these issues, converters can prevent future web breaks in the dispensing process. “To help our customers overcome these diecutting challenges, we deliver high-precision tools that are perfectly customized to the customers’ wishes and applications,” he says. “The most important thing is a very open exchange and discussion with customers and other market partners for mutual benefit.”

There has been a trend toward the increased usage of very thin filmic liners with a thickness of 23 microns and less, and they are used with even thinner filmic face materials like an MDO. “These thin liners are very demanding in terms of diecutting because they are not compressible like glassine liners, and thus much more sensitive for die strikes,” explains Gysbers. “To achieve perfect diecutting results, all components need to be in a perfect and absolutely clean condition: the diecutting unit and its cylinders, and of course the cutting tool, as well.”

When dealing with substrates, Wink recommends using its GapControl adjustable anvil roller. The company also utilizes special engraving and hardening techniques for its SuperCut dies to guarantee minimum tolerances.

According to Kocher + Beck’s Morris, there are several ways to deal with the move to thinner liners. Currently, converters are using main thin liners with thicknesses of .92 (23 microns). However, many are experimenting with .75 (19 microns), while even giving consideration to .5 (12-13 micron) in the future. “When going to such liners, the level of control the press operator has over the diecutting result is significantly reduced, and all components of the die station and tooling have to be in perfect condition,” he says. “It is important that converters work with their die supplier, to not only make sure they are ordering the correct tools, but to also have audits done on the anvils, magnetic cylinders and other components of the station.”

Training day

The rotary diecutting experts agree that specialized training is a critical aspect to successful finishing. Wink has a technical sales team to provide support and service, especially for customers working with very challenging substrates. In addition, Wink has an “ABC of diecutting” brochure for immediate troubleshooting, as well as individual training sessions for customers.

Kocher +Beck trains all of its regional sales managers to navigate substrate thickness and offers the appropriate equipment, from performing audits on anvils to providing the proper magnetic cylinders. “We are seeing more converters installing our world renowned GapMaster adjustable anvil system, which, with its ultra-fine level of adjustment, allows us to increase the level of control a press operator can have on such thin liners,” says Morris.

In addition to the training that Kocher + Beck provides for its staff, the company has recently finished doubling the size of its Kansas production facility. This initiative includes a substantial investment in additional equipment. Kocher + Beck anticipates that the expansion will further streamline its production process and shorten delivery times, but offer higher quality and better product knowledge to its customers.

“With all the advancements in diecutting technology, narrow web label converters should be sure they are training their operators on the nuances of their machinery to ensure top performance,” states Delta ModTech’s Newville. “We often see cases of under-utilized presses because the operators continue to run the machines in the same fashion as legacy equipment.”

Delta ModTech also prides itself on customer service, ranging from quotation to production. “We make sure each machine is up and running at installation and continue to work with our customers to make sure that they have the right resources to keep their machines running, expand their markets and keep their business profitable,” adds Newville.

RotoMetrics offers its customers a team of application advisors, engineers, master technicians, craftsmen and specialists. According to the company, it achieves 99% on-time delivery. RotoMetrics has evolved from a traditional tooling manufacturer into a global service provider. The company has online ordering and a tracking tool called MyRoto to give customers a 24/7 service to help them excel in a fast pace environment.

According to Kretzschmar, RotoMetrics strives to meet its goal of “Unlocking the Power of Precision.” He says, “Our customers rely on a well-connected supplier network with business partners offering reliable solutions and products extensively tested to exceed industry standards that work out of the box the first time, every time,” adds Kretzschmar. “We at RotoMetrics spend a tremendous amount of time developing tooling solutions before the launch of new materials. This is a service a converter should request from their suppliers.”

The industry has seen a considerable shift toward flexible dies in recent years. As Andre Gysbers, marketing director at Wink, explains, flexible dies are the first choice for many label and narrow web applications. Production and delivery have become much timelier, and converters can diecut unique shapes and angles. Special surface treatment products have made flexible dies far more durable, as well, which alleviates some of those concerns when compared to solid tooling.

“With increased speeds, automation and shorter downtimes, there are general trends toward diversification, specialties and smaller runs, as well as increased quality demands from end consumers and brand owners,” says Gysbers. “This has had a strong influence on diecutting technology. The general quality level has been increased, and many refinements/surface treatments have been established to optimize performance for various applications.”

Wink offers a complete range of rotary diecutting tools and equipment. The company features SuperCut flexible dies with various finishing options for many label and narrow web applications. In addition, Wink offers a complete range of rotary cylinders, including solid dies, magnetic, printing, sheeting and anvil cylinders, and also the GapControl adjustable anvil system, diecutting stations and pressure gauges. “Especially here at Wink, we have invested a lot in machinery, technology and personnel so that we were able to reduce die tolerances to a minimum, while at the same time producing high-precision and consistent quality very efficiently,” explains Gysbers.

Kocher + Beck sees advances in tooling, as well as with ancillary equipment used in the rotary diecutting process. “Within the production of flexible dies, all blade profiles are fully CNC machine sharpened, with height tolerances being held within microns as standard,” explains David Morris, president of Kocher + Beck USA. “We also offer a range of coatings for additional applications, as well as laser hardening to give increased die life.” Kocher + Beck also offers label converters the GapMaster adjustable anvil system, which allows extremely fine adjustment of the depth of cut while the press is running.

Flexible dies are suited to handle pressure sensitive materials, as the industry shifts more toward synthetic face materials and thinner liners. Kocher + Beck has seen a number of its products work seamlessly for rotary diecutting, including its high-precision flexible dies and magnetic cylinders. In addition to the GapMaster system, customized cutting stations and solid rotary cutters earmarked for specialized applications are also applicable.

Tooling suppliers have answered the demands for process improvement, much like other facets of the label and packaging industry. Brand owners, graphic designers and retailers are facing the challenge of reducing resource consumption and waste. Meanwhile, converters are using thinner materials and need finishing tools that provide tighter tolerances and last longer. “We, as a tooling supplier, have to reinvent ourselves to keep up with the always changing market requirements,” explains Ulrich Kretzschmar, global product and business development, RotoMetrics. “As an example, plate height tolerances of a rotary cutting tool converting a thin PET liner for beverage labels have to be five times tighter than one for a paper liner, which was the standard not too long ago.”

RotoMetrics manufactures a wide range of rotary tooling options, including solid and flexible dies, magnetic cylinders, anvils, print cylinders and sleeves, plus accessories. “Our customers need precision tools, and they need them fast,” adds Kretzschmar. “We have optimized the manufacturing process to allow us to finish flexible dies in several hours – instead of days. A fair share of the more than 1,100 flex dies we produce daily ship the same day from our manufacturing facilities on five continents. Improved and optimized blade geometries, in combination with dedicated finishing processes, opened the doors to new opportunities utilizing flexible die technology outside the tag and label markets.”

There is a financial benefit to flexible dies, too. According to Markus Marfurt, president and CEO of Electro Optic, flexible die systems cost roughly 25% less than traditional diecutting tools. “Flexible die tools from Electro Optic work as good or better than solid tools, consequently resulting in the expected cost reduction when using them,” explains Marfurt. “Changing market demands, such as digital printing, require fast, reliable and cost effective diecutting tool solutions.”

Electro Optic specializes in the manufacturing of flexible dies. The company’s Gold Line Special Flexible Die has been designed to address the die strike consistency of the thin gauge liner materials. These flexible dies also meet critical cutting requirements for challenging facestocks like MDO (machine direction orientation). Electro Optic’s DURA coating provides a greater longevity for highly abrasive substrates, such as thermal transfer, or higher volume jobs like those seen on thinner gauges. Also, the DURA coating has been designed to improve die life significantly. The product may also include extra hardening and coating processes.

Technological enhancements have also allowed converters to generate tighter tolerances. “The move to fully servo-driven diecutting systems has given converters the ability to have computer controlled registration and allows for extremely tight tolerance cutting,” explains Dave Grenwis, marketing manager at Delta ModTech. “Along with constant advancements in software programing, the manufacturing of rotary dies, gearing and sensors continues to allow for increased speed and consistent cuts.”

Delta ModTech provides rotary diecuting capabilities for all of its machine offerings. The Crusader Converter is an entry-level diecutting platform for general web converting applications, and the company finds that it is popular for contract converters and R&D environments. Additionally, the Spectrum Finishing System is a digital print finishing system, which Delta ModTech describes as its most flexible solution for diecutting digitally printed webs, allowing for both semi-rotary and full rotary cutting. “We also build custom turn-key diecutting systems using the same modular platform found on all of our machines,” says Grenwis. “These systems range from advanced label finishing systems to transdermal patch manufacturing machines to fully integrated IVD manufacturing lines.”

Wilson has nearly 40 years of experience in the medical, automotive and label industries. Priding itself on the knowledge and technical support it can provide to its clients, the company offers everything from machine-sharpened rotary dies to magnetic and print cylinders. Wilson’s cylinders are manufactured with automated CNC machinery to assure accuracy and consistency, as well as containing ceramic and rare earth magnets. The machine-sharpened dies were created for abrasive, tight tolerances and long-run applications.

“Machine sharpening has been the key to technology growth, allowing for tighter tolerance, consistency and angles required for today’s thin films,” explains Wade Fouts, VP at Wilson Manufacturing. “We supply the finishing accessories including, but not limited to, magnetic cylinders, solid, flexible, anvil rolls, and print cylinders.”

There is still a need for solid tooling, though. Solid tools are still relied upon for high-caliper material, as the longer blade height can accommodate thicker materials. Marfurt adds that solid tools may outperform alternative diecutting options in steel-to-steel applications, especially when dealing with long fiber content, such as fabrics and certain films.

“Diecutting with solid tooling is still the best choice for long runs,” says Jason Newville, design engineer at Delta ModTech. “Full rotary cutting allows for the highest speeds available. However, semi-rotary cutting is catching up. Solid tooling can also last longer before its needs sharpening.”

Gysbers states that companies will also opt for solid tooling – including air eject and pin eject systems – when there is a need to remove waste from the web and/or tooling.

Today flexible dies are seeing increased technological capabilities to handle materials that were once not feasible. “Although we continue to see more areas of the converting industry moving to flexible dies, there will always be those where a solid rotary tool is better suited,” says Morris. “This, however, is in the more specialized applications where thicker stocks are being used, although even here we are seeing a move – where possible – to flexible tooling.”

Navigating substrates

Substrates can pose a challenge in rotary diecutting. In addition to meeting faster delivery times, converters must navigate substrates that – while appealing on the shelf – are difficult to finish.

“Substrates always have and always will affect the rotary cutting process,” explains Wilson’s Fouts. “This is why it is important your supplier is knowledgeable in regards to the characteristics of all substrates to assist you in choosing the right tooling.”

“Challenging substrates, such as MDOs, require very sharp cutting properties to offset the vertical and horizontal difference on strength built into the substrate,” says Electro Optic’s Marfurt. “Highly abrasive contents, such as encounters with thermal transfer materials or certain inks, will reduce the tool life significantly.”

According to Wink’s Gysbers, the main challenges in rotary diecutting center on the substrates. Die strikes on the liner need to be avoided, since they essentially damage the liner. By avoiding these issues, converters can prevent future web breaks in the dispensing process. “To help our customers overcome these diecutting challenges, we deliver high-precision tools that are perfectly customized to the customers’ wishes and applications,” he says. “The most important thing is a very open exchange and discussion with customers and other market partners for mutual benefit.”

There has been a trend toward the increased usage of very thin filmic liners with a thickness of 23 microns and less, and they are used with even thinner filmic face materials like an MDO. “These thin liners are very demanding in terms of diecutting because they are not compressible like glassine liners, and thus much more sensitive for die strikes,” explains Gysbers. “To achieve perfect diecutting results, all components need to be in a perfect and absolutely clean condition: the diecutting unit and its cylinders, and of course the cutting tool, as well.”

When dealing with substrates, Wink recommends using its GapControl adjustable anvil roller. The company also utilizes special engraving and hardening techniques for its SuperCut dies to guarantee minimum tolerances.

According to Kocher + Beck’s Morris, there are several ways to deal with the move to thinner liners. Currently, converters are using main thin liners with thicknesses of .92 (23 microns). However, many are experimenting with .75 (19 microns), while even giving consideration to .5 (12-13 micron) in the future. “When going to such liners, the level of control the press operator has over the diecutting result is significantly reduced, and all components of the die station and tooling have to be in perfect condition,” he says. “It is important that converters work with their die supplier, to not only make sure they are ordering the correct tools, but to also have audits done on the anvils, magnetic cylinders and other components of the station.”

Training day

The rotary diecutting experts agree that specialized training is a critical aspect to successful finishing. Wink has a technical sales team to provide support and service, especially for customers working with very challenging substrates. In addition, Wink has an “ABC of diecutting” brochure for immediate troubleshooting, as well as individual training sessions for customers.

Kocher +Beck trains all of its regional sales managers to navigate substrate thickness and offers the appropriate equipment, from performing audits on anvils to providing the proper magnetic cylinders. “We are seeing more converters installing our world renowned GapMaster adjustable anvil system, which, with its ultra-fine level of adjustment, allows us to increase the level of control a press operator can have on such thin liners,” says Morris.

In addition to the training that Kocher + Beck provides for its staff, the company has recently finished doubling the size of its Kansas production facility. This initiative includes a substantial investment in additional equipment. Kocher + Beck anticipates that the expansion will further streamline its production process and shorten delivery times, but offer higher quality and better product knowledge to its customers.

“With all the advancements in diecutting technology, narrow web label converters should be sure they are training their operators on the nuances of their machinery to ensure top performance,” states Delta ModTech’s Newville. “We often see cases of under-utilized presses because the operators continue to run the machines in the same fashion as legacy equipment.”

Delta ModTech also prides itself on customer service, ranging from quotation to production. “We make sure each machine is up and running at installation and continue to work with our customers to make sure that they have the right resources to keep their machines running, expand their markets and keep their business profitable,” adds Newville.

RotoMetrics offers its customers a team of application advisors, engineers, master technicians, craftsmen and specialists. According to the company, it achieves 99% on-time delivery. RotoMetrics has evolved from a traditional tooling manufacturer into a global service provider. The company has online ordering and a tracking tool called MyRoto to give customers a 24/7 service to help them excel in a fast pace environment.

According to Kretzschmar, RotoMetrics strives to meet its goal of “Unlocking the Power of Precision.” He says, “Our customers rely on a well-connected supplier network with business partners offering reliable solutions and products extensively tested to exceed industry standards that work out of the box the first time, every time,” adds Kretzschmar. “We at RotoMetrics spend a tremendous amount of time developing tooling solutions before the launch of new materials. This is a service a converter should request from their suppliers.”