Greg Hrinya, Associate Editor09.11.17

In the quest to provide a cost-effective product while decreasing their environmental footprint, film substrate suppliers continue to be constructed with thinner face and liner materials. To achieve this, films can be teamed with various adhesives and liners to develop a product that really pops on the shelf.

Films can range from rigid to conformable, and labels often include BOPP, PET, PE, polypropylene and polyolefin materials. Films are increasingly being relied upon in multiple applications, especially as brands look for alternatives to move away from glue-applied labels or other labeling methods.

From food and beverage to personal care, films have something to offer a wide range of converters. “The trend continues to be a clear no-label look,” says Bruce Ruppert, product development, Americas, UPM Raflatac. “Clear BOPP, PET and polyolefin labels are now being used in the home and personal care and beverage markets, as well as in pharmaceuticals, and this has been expanding more and more into food and beverage applications.”

White and silver metalized films are frequently utilized in today’s marketplace, especially with beverages and spirits. End users are also requesting thinner gauge films for multiple packaging types like conformable, rigid and squeezable.

“The standard films in our industry continue to be 2.0 mil clear top-coated and 2.6 mil white top-coated polypropylene materials,” says Ruppert. “These have been a standard in the industry for years. Lower gauge versions, such as 1.6 mil clear polypropylene and 2.4 mil white polypropylene, continue to replace these standards for those looking to improve both economics and sustainability.”

Films are also seeing a boost in the craft space. “I think a huge opportunity for us is in the growth of craft, not just in beer but across other beverages and products,” says Anh Marella, senior product manager, Select Solutions at Avery Dennison. “There are craft candles and craft coffees – there is growth and localization of those types of products, where you do need a material that’s available to the customer faster and in smaller quantities. It’s so that they can make their seasonal brews or varietals.”

As short runs and customization become more prevalent, more converters require filmic solutions to accommodate the digital printing market. Suppliers are tasked with developing films that can handle this growing trend. “More and more converters are looking for materials to print on their new digital equipment,” explains Joel Ulrich, roll product manager at Spinnaker Coating. “We have to continue to research and develop the right films with the right top-coatings to support all of the digital technologies in the market. One trend we are seeing is the need for glossy films for the water-based inkjet segment. It seems everyone is working hard to develop a gloss top-coating that provides the needed quick dry properties and ink anchorage requirements for this technology.”

According to Patricia Mulvey, marketing manager at Green Bay Packaging, customer requirements will ultimately determine the company’s R&D initiatives. “Our development efforts are driven by our customers’ needs,” she says. “While not all converters are moving to thinner films, we do have those who want the price and ecological advantages that these films provide. While 2.6 mil white BOPP remains popular, a great number of our customers have switched to the 2.4 mil version. This change also includes a switch from a 1.2 mil PET liner to one that is .92 mils thick. We are also working with customers who want to go even thinner with both their faces and liners, which means going down to a liner of .75 mil.”

John Bennett, vice president of the Product Identification Business team at FLEXcon, says that films used for durable goods labeling have certain requirements. Compliance standards like GHS (Globally Harmonized System) have been used for certain chemicals, and filmstock manufacturers play a key role in this space. “The standards come all the way back up the line to a PS film supplier like FLEXcon, because suddenly an application that was variable-printed via a monochrome printer now requires color – and this can change top-coating technology, liner and film selection based on a variable print medium, and so on,” says Bennett.

Digital Developments, Going Green

The proliferation of digital print technology is playing a role in film substrate development, in addition to the drive toward being more sustainable and cost-effective.

“Films are getting thinner and thinner, trying to be more sustainable and cost competitive for customers – I think that’s a major trend that we’ve seen for quite a while,” says Avery Dennison’s Marella. “I think we’re also seeing – with the rise of digital print technology – films that work with both UV inkjet and water-based inkjet processes. There are different film topcoats used in order to facilitate films being able to work with the various print technologies.”

For Green Bay Packaging, the key is developing substrates that can work with a multitude of presses – both conventional and digital. “With so many new presses, ink systems and curing equipment, ensuring that the buyers of these presses have access to the label materials they need is a constantly evolving challenge,” explains Green Bay Packaging’s Mulvey. “Even with one type of press, like UV inkjet, the variance in what will print on one type of press brand versus another has necessitated the sourcing of technology-specific materials, or top-coating current stock to ensure compatibility.”

Increasingly, label customers are relying on films to provide security, as well. “Cradle-to-grave product tracking has been in higher demand regarding product authenticity, the ability to limit liability, and anti-counterfeit issues,” explains FLEXcon’s Bennett. “We are working every day with customers to develop products that will now be printed both analog and digital, and can be as simple as replacing a former nameplate on a component part. Being able to print a QR code on an item that will give the consumer product information is not only in the primary label markets for consumable goods. This concept of incorporating data into a static label is finding its way into the durable markets.”

Sustainability remains a concern throughout all areas of the supply chain. “We always recommend our CleanFlake adhesive,” says Marella. “With companies wanting to have an eco-friendly footprint, along with the growth of beverage and water label markets – specifically with PET bottles – it’s an opportunity for us to drive the recycling of PET.”

Many brand owners are continuosly looking to reduce the amount of packaging material they use along with the associated costs. The goal is to improve efficiency and increase profits.

UPM Raflatac recently launched its RW85C adhesive, which was developed to pass the APR (Association of Plastic Recyclers) recycling requirements for PET clamshells and bottles. “Brand owners are looking to move toward more recyclable packaging or to use more recycled content in their packaging,” explains UPM Raflatac’s Ruppert. “Packaging types continue to evolve and end users haven’t always paid particular attention to the label materials they are using and how that may impact packaging design and recyclability. Now, the label is being recognized more and more as the next step in package evolution for packaging engineers.”

According to Tyler Matusevich, senior sustainability specialist, Americas, UPM Raflatac, sustainability in the films space can be met in two ways. First is the continued down-gauging of both face and liner materials, while the second involves new product designs in both substrates and adhesives. “Our new product combinations were developed specifically for customers that truly want to provide a more sustainable product,” says Matusevich. “Additionally, our PE 65 film materials are beneficial in receiving store drop-off recyclability for PE pouches.”

Thin To Win?

With the label industry increasingly shifting to thinner gauge films, there are several challenges associated with the trend that need to be overcome, however.

Melissa Walsh, marketing communications and digital product manager at Acucote, explains: “Web handling and processing can be a challenge,” she says. “The thinner the film the more challenging it is to run seamlessly through equipment. It can lead to potential effects of elongation due to the elasticity of the films.”

“Thinner materials bring better yields and cost control along with the tangent benefits of being more environmentally-friendly,” says FLEXcon’s Bennett. “The challenge this brings is in the area of web control with a demand for better tension systems, web handling systems, more accurate diecutting, thinner release liners and more dynamic dispensing systems.”

These challenges can also be application-specific. “The biggest challenge we face with thinner gauge films is really understanding the needs of our specific customers when it comes to thinner films,” says Spinnaker Coating’s Ulrich. “Just because the market has introduced a 1 mil polypropylene, it doesn’t mean that is what our customers are looking for.”

According to UPM Raflatac’s Ruppert, thinner films must account for a smaller operating window. “This means thinner films need improvement in process control, and in some cases improved equipment, to meet current waste and productivity goals,” he says. “One example is the development of new adhesives such as our RP74 and RP76. These were both specifically designed to be used on these types of films to reduce issues such as edge ooze.”

Ruppert adds that thinner films have lower stiffness values, and if the stiffness of the face is not high enough compared to the release of the material, the label will not dispense. This issue can be overcome with a sharper peel plate and higher tension on the applicator.

“When liners are down-gauged below 1.2 mil, the window of operation tends to become much smaller,” says Ruppert. “Many have discovered improved maintenance of die stations is required, as improved dies and tighter tolerances on magnetic cylinders have been necessary. Converters have also turned to adjustable anvils, an aftermarket addition to the die station, to open the process window and allow for different caliper liners or the variation between different suppliers.”

On the substrate manufacturing side, Green Bay Packaging has not run into any issues with thinner films. “We have not had challenges converting the thinner films on our coaters and slitters,” says Mulvey. “The greater challenges are for our customers and the end users. Our customers have to retool for the thinner materials and concern themselves with the tighter diecutting tolerances. Of course, at the end user stage, dispensing and application can be issues as the stiffness is reduced with the thinner films.”

Plethora Of Products

With the arrival of Labelexpo Europe, suppliers are touting their latest innovations in the films space. Acucote Inc. has a variety of film-based facestocks for pressure sensitive applications. Offering prime to industrial films, Acucote stocks polypropylenes, polystyrenes, polyesters, vinyls and Tyvek. “We continue to expand our line of topcoated films for water-based inkjet dye, water-based inkjet pigment, UV inkjet and HP digital print systems,” says Acucote’s Walsh. “Our line of films for security and anti-counterfeiting has also seen growth.”

Avery Dennison provides a wide range of products within its portfolios, from rigid films all the way to conformable films. In addition to a portfolio designed for digital inkjet printing, Avery Dennison is promoting Primax and FasClear films, which are white and clear conformable films, respectively. They feature thinner and clearer materials and are designed to help converters overcome diecutting challenges. “I think what customers love about these products, in a lot of cases, PE or conformable films have a slight haze to them,” explains Avery Dennison’s Marella. “This product is significantly clearer. When you’re looking at applications like home and personal care, where you’ve got a clear bottle and you really want to see the product, this label and the clarity of it was something that people were really surprised with compared to what they had been using.”

FLEXcon’s product range runs the gamut throughout pressure sensitive applications. The company’s Product Identification films are designed for label applications that are on the container, be it a shampoo bottle, a chainsaw, a pharmaceutical or a drum label. “Our Performance Products are designed for component parts like gaskets, bonding and mounting applications, membrane switch applications and healthcare products,” says Bennett. “If it’s on it, about it or in it, FLEXcon can supply it.”

FLEXcon’s array of pressure sensitive film choices include PET, PVC (cast and calendered), PP, PE, acrylic, polyimide, PVDF and even designer polymers, to meet any application need. “When you combine our film, topcoat, adhesive and release liner, it amounts to almost 5,000 unique products that FLEXcon manufactures on an annual basis,” adds Bennett.

Most recently, the company began offering sureFLEX, which is a PE/PP film that can be utilized for primary labeling applications. FLEXcon also has a new white opaque cast vinyl, DPM Cast White Opaque Sheet, for outdoor power equipment and other applications that demand the conformability of cast PVC.

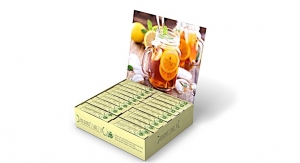

Green Bay Packaging’s films are often being used in primary label applications, on both rigid and squeezable containers. The decision to use a film for these applications can be image driven, as it is said the no-label look is perceived as more upscale. The films also serve functional purposes when there is a need for moisture resistance or other durability factors. “We offer our films with both acrylic emulsion and hot melt adhesives,” says Mulvey. “The acrylic emulsion is perfect for consumer product labeling. The hot melt adhesives are designed for more durable applications.”

Mulvey adds that Label-Lyte films with a pearlescent look remain a favorite among Green Bay Packaging customers.The company is also offering a new 2.3 mil solid white film that has the same top coating as Label-Lyte films.

Spinnaker Coating offers more than 40 different film substrates – from clear and white polypropylene to more specialized options, including metalized films, polyesters, vinyl and Kimdura brand products.

“We offer our film products with a variety of adhesive combinations, from general purpose adhesives to textured surface adhesives, removable options, and many cold temperature offerings for food and outdoor use,” explains Spinnaker Coating’s Ulrich. “Two of our newer film facestocks are DiversiPrint Poly and 2.8 mil Thermal Transfer Film. DiversiPrint Poly is a matte white polyester film designed to print via both laser and water-based inkjet printing platforms, as well as flexography.”

Spinnaker’s PrimeScan facestock is commonly requested because of its versatility, Ulrich says, adding that the company’s 3.3 mil Durable Polypropylene continues to be “a work horse.”

UPM Raflatac offers standard and thin gauge clear, white and metalized films. “Our specials group has products for the durable, security and other specialty markets,” says Ruppert. “Recent additions to our standard film offering include Clear and White Raflex MDO materials. These products give you another tool in your label toolbox for those applications that need an affordable conformable film but require a little more flexibility than our more traditional films.”

Films can range from rigid to conformable, and labels often include BOPP, PET, PE, polypropylene and polyolefin materials. Films are increasingly being relied upon in multiple applications, especially as brands look for alternatives to move away from glue-applied labels or other labeling methods.

From food and beverage to personal care, films have something to offer a wide range of converters. “The trend continues to be a clear no-label look,” says Bruce Ruppert, product development, Americas, UPM Raflatac. “Clear BOPP, PET and polyolefin labels are now being used in the home and personal care and beverage markets, as well as in pharmaceuticals, and this has been expanding more and more into food and beverage applications.”

White and silver metalized films are frequently utilized in today’s marketplace, especially with beverages and spirits. End users are also requesting thinner gauge films for multiple packaging types like conformable, rigid and squeezable.

“The standard films in our industry continue to be 2.0 mil clear top-coated and 2.6 mil white top-coated polypropylene materials,” says Ruppert. “These have been a standard in the industry for years. Lower gauge versions, such as 1.6 mil clear polypropylene and 2.4 mil white polypropylene, continue to replace these standards for those looking to improve both economics and sustainability.”

Films are also seeing a boost in the craft space. “I think a huge opportunity for us is in the growth of craft, not just in beer but across other beverages and products,” says Anh Marella, senior product manager, Select Solutions at Avery Dennison. “There are craft candles and craft coffees – there is growth and localization of those types of products, where you do need a material that’s available to the customer faster and in smaller quantities. It’s so that they can make their seasonal brews or varietals.”

As short runs and customization become more prevalent, more converters require filmic solutions to accommodate the digital printing market. Suppliers are tasked with developing films that can handle this growing trend. “More and more converters are looking for materials to print on their new digital equipment,” explains Joel Ulrich, roll product manager at Spinnaker Coating. “We have to continue to research and develop the right films with the right top-coatings to support all of the digital technologies in the market. One trend we are seeing is the need for glossy films for the water-based inkjet segment. It seems everyone is working hard to develop a gloss top-coating that provides the needed quick dry properties and ink anchorage requirements for this technology.”

According to Patricia Mulvey, marketing manager at Green Bay Packaging, customer requirements will ultimately determine the company’s R&D initiatives. “Our development efforts are driven by our customers’ needs,” she says. “While not all converters are moving to thinner films, we do have those who want the price and ecological advantages that these films provide. While 2.6 mil white BOPP remains popular, a great number of our customers have switched to the 2.4 mil version. This change also includes a switch from a 1.2 mil PET liner to one that is .92 mils thick. We are also working with customers who want to go even thinner with both their faces and liners, which means going down to a liner of .75 mil.”

John Bennett, vice president of the Product Identification Business team at FLEXcon, says that films used for durable goods labeling have certain requirements. Compliance standards like GHS (Globally Harmonized System) have been used for certain chemicals, and filmstock manufacturers play a key role in this space. “The standards come all the way back up the line to a PS film supplier like FLEXcon, because suddenly an application that was variable-printed via a monochrome printer now requires color – and this can change top-coating technology, liner and film selection based on a variable print medium, and so on,” says Bennett.

Digital Developments, Going Green

The proliferation of digital print technology is playing a role in film substrate development, in addition to the drive toward being more sustainable and cost-effective.

“Films are getting thinner and thinner, trying to be more sustainable and cost competitive for customers – I think that’s a major trend that we’ve seen for quite a while,” says Avery Dennison’s Marella. “I think we’re also seeing – with the rise of digital print technology – films that work with both UV inkjet and water-based inkjet processes. There are different film topcoats used in order to facilitate films being able to work with the various print technologies.”

For Green Bay Packaging, the key is developing substrates that can work with a multitude of presses – both conventional and digital. “With so many new presses, ink systems and curing equipment, ensuring that the buyers of these presses have access to the label materials they need is a constantly evolving challenge,” explains Green Bay Packaging’s Mulvey. “Even with one type of press, like UV inkjet, the variance in what will print on one type of press brand versus another has necessitated the sourcing of technology-specific materials, or top-coating current stock to ensure compatibility.”

Increasingly, label customers are relying on films to provide security, as well. “Cradle-to-grave product tracking has been in higher demand regarding product authenticity, the ability to limit liability, and anti-counterfeit issues,” explains FLEXcon’s Bennett. “We are working every day with customers to develop products that will now be printed both analog and digital, and can be as simple as replacing a former nameplate on a component part. Being able to print a QR code on an item that will give the consumer product information is not only in the primary label markets for consumable goods. This concept of incorporating data into a static label is finding its way into the durable markets.”

Sustainability remains a concern throughout all areas of the supply chain. “We always recommend our CleanFlake adhesive,” says Marella. “With companies wanting to have an eco-friendly footprint, along with the growth of beverage and water label markets – specifically with PET bottles – it’s an opportunity for us to drive the recycling of PET.”

Many brand owners are continuosly looking to reduce the amount of packaging material they use along with the associated costs. The goal is to improve efficiency and increase profits.

UPM Raflatac recently launched its RW85C adhesive, which was developed to pass the APR (Association of Plastic Recyclers) recycling requirements for PET clamshells and bottles. “Brand owners are looking to move toward more recyclable packaging or to use more recycled content in their packaging,” explains UPM Raflatac’s Ruppert. “Packaging types continue to evolve and end users haven’t always paid particular attention to the label materials they are using and how that may impact packaging design and recyclability. Now, the label is being recognized more and more as the next step in package evolution for packaging engineers.”

According to Tyler Matusevich, senior sustainability specialist, Americas, UPM Raflatac, sustainability in the films space can be met in two ways. First is the continued down-gauging of both face and liner materials, while the second involves new product designs in both substrates and adhesives. “Our new product combinations were developed specifically for customers that truly want to provide a more sustainable product,” says Matusevich. “Additionally, our PE 65 film materials are beneficial in receiving store drop-off recyclability for PE pouches.”

Thin To Win?

With the label industry increasingly shifting to thinner gauge films, there are several challenges associated with the trend that need to be overcome, however.

Melissa Walsh, marketing communications and digital product manager at Acucote, explains: “Web handling and processing can be a challenge,” she says. “The thinner the film the more challenging it is to run seamlessly through equipment. It can lead to potential effects of elongation due to the elasticity of the films.”

“Thinner materials bring better yields and cost control along with the tangent benefits of being more environmentally-friendly,” says FLEXcon’s Bennett. “The challenge this brings is in the area of web control with a demand for better tension systems, web handling systems, more accurate diecutting, thinner release liners and more dynamic dispensing systems.”

These challenges can also be application-specific. “The biggest challenge we face with thinner gauge films is really understanding the needs of our specific customers when it comes to thinner films,” says Spinnaker Coating’s Ulrich. “Just because the market has introduced a 1 mil polypropylene, it doesn’t mean that is what our customers are looking for.”

According to UPM Raflatac’s Ruppert, thinner films must account for a smaller operating window. “This means thinner films need improvement in process control, and in some cases improved equipment, to meet current waste and productivity goals,” he says. “One example is the development of new adhesives such as our RP74 and RP76. These were both specifically designed to be used on these types of films to reduce issues such as edge ooze.”

Ruppert adds that thinner films have lower stiffness values, and if the stiffness of the face is not high enough compared to the release of the material, the label will not dispense. This issue can be overcome with a sharper peel plate and higher tension on the applicator.

“When liners are down-gauged below 1.2 mil, the window of operation tends to become much smaller,” says Ruppert. “Many have discovered improved maintenance of die stations is required, as improved dies and tighter tolerances on magnetic cylinders have been necessary. Converters have also turned to adjustable anvils, an aftermarket addition to the die station, to open the process window and allow for different caliper liners or the variation between different suppliers.”

On the substrate manufacturing side, Green Bay Packaging has not run into any issues with thinner films. “We have not had challenges converting the thinner films on our coaters and slitters,” says Mulvey. “The greater challenges are for our customers and the end users. Our customers have to retool for the thinner materials and concern themselves with the tighter diecutting tolerances. Of course, at the end user stage, dispensing and application can be issues as the stiffness is reduced with the thinner films.”

Plethora Of Products

With the arrival of Labelexpo Europe, suppliers are touting their latest innovations in the films space. Acucote Inc. has a variety of film-based facestocks for pressure sensitive applications. Offering prime to industrial films, Acucote stocks polypropylenes, polystyrenes, polyesters, vinyls and Tyvek. “We continue to expand our line of topcoated films for water-based inkjet dye, water-based inkjet pigment, UV inkjet and HP digital print systems,” says Acucote’s Walsh. “Our line of films for security and anti-counterfeiting has also seen growth.”

Avery Dennison provides a wide range of products within its portfolios, from rigid films all the way to conformable films. In addition to a portfolio designed for digital inkjet printing, Avery Dennison is promoting Primax and FasClear films, which are white and clear conformable films, respectively. They feature thinner and clearer materials and are designed to help converters overcome diecutting challenges. “I think what customers love about these products, in a lot of cases, PE or conformable films have a slight haze to them,” explains Avery Dennison’s Marella. “This product is significantly clearer. When you’re looking at applications like home and personal care, where you’ve got a clear bottle and you really want to see the product, this label and the clarity of it was something that people were really surprised with compared to what they had been using.”

FLEXcon’s product range runs the gamut throughout pressure sensitive applications. The company’s Product Identification films are designed for label applications that are on the container, be it a shampoo bottle, a chainsaw, a pharmaceutical or a drum label. “Our Performance Products are designed for component parts like gaskets, bonding and mounting applications, membrane switch applications and healthcare products,” says Bennett. “If it’s on it, about it or in it, FLEXcon can supply it.”

FLEXcon’s array of pressure sensitive film choices include PET, PVC (cast and calendered), PP, PE, acrylic, polyimide, PVDF and even designer polymers, to meet any application need. “When you combine our film, topcoat, adhesive and release liner, it amounts to almost 5,000 unique products that FLEXcon manufactures on an annual basis,” adds Bennett.

Most recently, the company began offering sureFLEX, which is a PE/PP film that can be utilized for primary labeling applications. FLEXcon also has a new white opaque cast vinyl, DPM Cast White Opaque Sheet, for outdoor power equipment and other applications that demand the conformability of cast PVC.

Green Bay Packaging’s films are often being used in primary label applications, on both rigid and squeezable containers. The decision to use a film for these applications can be image driven, as it is said the no-label look is perceived as more upscale. The films also serve functional purposes when there is a need for moisture resistance or other durability factors. “We offer our films with both acrylic emulsion and hot melt adhesives,” says Mulvey. “The acrylic emulsion is perfect for consumer product labeling. The hot melt adhesives are designed for more durable applications.”

Mulvey adds that Label-Lyte films with a pearlescent look remain a favorite among Green Bay Packaging customers.The company is also offering a new 2.3 mil solid white film that has the same top coating as Label-Lyte films.

Spinnaker Coating offers more than 40 different film substrates – from clear and white polypropylene to more specialized options, including metalized films, polyesters, vinyl and Kimdura brand products.

“We offer our film products with a variety of adhesive combinations, from general purpose adhesives to textured surface adhesives, removable options, and many cold temperature offerings for food and outdoor use,” explains Spinnaker Coating’s Ulrich. “Two of our newer film facestocks are DiversiPrint Poly and 2.8 mil Thermal Transfer Film. DiversiPrint Poly is a matte white polyester film designed to print via both laser and water-based inkjet printing platforms, as well as flexography.”

Spinnaker’s PrimeScan facestock is commonly requested because of its versatility, Ulrich says, adding that the company’s 3.3 mil Durable Polypropylene continues to be “a work horse.”

UPM Raflatac offers standard and thin gauge clear, white and metalized films. “Our specials group has products for the durable, security and other specialty markets,” says Ruppert. “Recent additions to our standard film offering include Clear and White Raflex MDO materials. These products give you another tool in your label toolbox for those applications that need an affordable conformable film but require a little more flexibility than our more traditional films.”