Steve Katz, Editor01.26.18

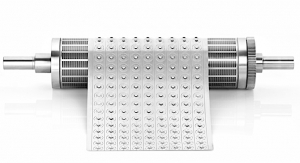

Diecutting is an integral and necessary part of label converting. Like other aspects of the process, dies and rotary diecutting technology have come a long way and continue to evolve. For evidence, just look at how the industry has fully embraced the transition from solid rotary tooling to flexible dies.

The evolution of this sector of the industry places strong emphasis on the supplier. With flexible dies, delivery and turnaround time are more important to converters than ever before. Also, die suppliers must take note of evolving print and substrate technologies such as the proliferation of digital printing and the move toward thinner materials.

L&NW recently caught up with the industry’s leading rotary diecutting specialists, who filled us in on new products and technologies, what they see as the key label industry trends, and the role they’re playing in influencing the diecutting sector of the market. And within the die and diecutting space, the following suppliers also share what sets them apart, as well as the advantages their products and services provide.

RotoMetrics

One of the more noteworthy M&A news stories from 2017 was RotoMetrics’ acquisition of flexible die specialist Electro Optic. The move underscores the prominent role flexible dies are now playing in the industry.

“As an integral part of the converting process, we want to help our customers get more business,” says Keith Laako, RotoMetrics’ VP of global marketing and business development. “We understand there is a growing demand in the market for unique packaging solutions and an increasing need for speed and efficiency. That is exactly why we brought together the two best tooling companies. Our combined operations offer the most innovative diecutting technology, plus the broadest product range in the market to offer customized solutions for every converting challenge.”

Laako stresses that by joining forces with Electro Optic, RotoMetrics now offers what he says is the industry’s most extensive materials database. “We know how to cut materials better. We build our products to meet and exceed our customers’ standards for precision, sharpness and longevity. We are continually evolving our products and practices to deliver better solutions. Plus, we make house calls for on-site problem solving in the places where our customers do business to make sure we understand their challenges.

“Labels are a business built on speed,” he adds. “We built our business to be fast and responsive to our customers’ needs. We use state-of-the-art technology to deliver optimum performance with speed that exceeds industry standards. Our streamlined supply chain precisely delivers what you need, where and when you need it. Combine all this with our uncompromising regard for deadlines and we deliver what we promised, when we promised it.”

Among the new products RotoMetrics’ customers are benefitting from include dies that have new RotoRepel No-Stick Treatment, which is designed to solve the toughest adhesive challenges. Available on solid (new and resharpened) and flexible dies, RotoRepel features an exclusive technology and formulation that minimizes adhesive pick-up and transfer. RotoRepel is now available globally.

RotoRepel has many advantages over current industry non-stick offerings, Laako says, noting it is ultra-thin and won’t chip or flake. Blade profiles remain precise even after treatment with RotoRepel as there is no coating buildup. Additionally, dies treated with RotoRepel will run longer before any adhesive build-up occurs. If there is any adhesive build-up, the dies easily wipe off. In most cases, dies are stored after use and can quickly go on press again without extensive cleaning. Overall, press setup and downtime are significantly reduced.

According to Butch Schomber, new product innovation manager for Rotometrics, “RotoRepel is the culmination of three years of extensive R&D, and we actually have a non-stick that really works on almost all adhesives. After months of field trials with both converters and material suppliers, RotoRepel continues to receive unprecedented feedback. Our test trial customers love RotoRepel. Not only is it allowing operators to run longer between die cleanings, it almost eliminates adhesive whip and drastically reduces label lift and contaminated product. Due to less die handling, our customers are also reporting a major drop in die damage caused in the cleaning process.”

On the Electro Optic side of the business, RotoMetrics offers the Gold Line Special flexible die that features no liner strike and what the company says is unmatched height parallelism due to Electro Optic’s patented processes. “New label materials create increasingly special demands on the precision of all components involved in diecutting. Successful diecutting on ultra-thin liners without die strike can only be accomplished by keeping the tolerances within the narrowest limits. Electro Optic’s Gold Line Special quality exactly meets this challenge,” Laako says.

Also popular among label converters within the Electro Optic product portfolio is the Dura Line flexible die, which is specifically designed to handle the most abrasive materials for longer die life and longer production runs. The company says Electro Optic’s manufacturing processes produce dies with considerable extra life compared to standard flexible dies on the most demanding materials, including abrasive papers, thermal papers, recycled papers and thin cardboard.

Electro Optic’s Dura Line coating provides surface hardness of more than 1,100 HV (in comparison: The laser hardening until 63 HRC ≈ 800 HV) protects the cutting lines against scrubbing of high gloss paper, thermal paper, matted foils, writeable colors and lacquers, luminescence inks, metallic inks, whitener and pastel colors.

With manufacturing support services on five continents, RotoMetrics and Electro Optic offer broad global distribution of precision tooling. The combined strengths of the two organizations allow for more products, to more people, in more places. Concludes Laako, “We believe our unique combination of exceptional people providing unparalleled support and reliable solutions create value and speed that are key to helping our customers succeed.”

Wink

Wink is a Germany-based diecutting specialist that operates under the mantra, “You cut, we care.” The company’s North American outpost, Wink US, LLC, is based in Charlotte, NC. In reviewing the state of the industry, Andre Gysbers, marketing director at Wink, says, “The most obvious trends are digitalization and automation, which of course have an impact on all industries. To maximize efficiency and productivity, label converters are searching for potential improvements along the whole value chain. While much of the developments focus on printing, the finishing process has become increasingly more crucial.”

Wink has addressed evolving finishing needs by developing a new version of its SmartGap anvil adjustable system, which is designed to fit perfectly into new automated environments. With SmartGap, the cylinder gap (clearance) can be adapted very precisely to different liners and fluctuating liner thicknesses, so that even with demanding applications and very thin liners, optimum diecutting results are achieved.

“The SmartGap system is very simple and flexible to operate,” Gysbers explains. “The operator can adapt the gap with greatest accuracy individually for the drive and operator side. Because the cutting depth does not have to be regulated via the pretension, the service life of the tools is increased at the same time. In contrast to other adjustable systems, the SmartGap does not have any limitations. The system even makes cutting-through (metal-to-metal) possible without any problems and results in extremely low-maintenance. With the ongoing shift towards more sophisticated labels and special applications that require high precision diecutting for extremely thin liner material, flawless diecutting on these liners is only possible using tooling such as our SmartGap adjustable anvil SuperCut “Special” dies with minimum tolerances.”

Supercut features Wink’s CNC-made flexible dies that take into account specific adjustments of the blade geometry for perfect diecutting of difficult materials and applications with very intricate shapes. The company also leverages its die coatings expertise to meet customer needs. Gysbers says, “We offer a unique range of finishing and coatings to maximize diecutting efficiency. Among these are our MCR “MicroChrome” coating, MC plus coating, laser hardening and four different non-stick coatings that provide long lifetimes even when used to cut abrasive labelstock or extreme adhesives.”

For 2018, Wink is planning the launch of the SmartGap “Touch.” The patent-pending system offers numerous smart functions, which lead increased in efficiencies with regard to the automation of production processes. Moreover, the new technology allows for gap adjustment steps of only half a micron. Upcoming feature packages will include job control functions, automatic gap control and MIS connectivity.

Wink recently launched the PerfoPlus line of flexible dies. “Many label and packaging applications include some kind of perforation in a variety of designs. Quite often, these perforations are difficult to achieve with conventionally produced flexible dies. Our new PerfoPlus flexible dies overcome these challenges. With patent-pending laser technology, the perforation cuts and ties are produced with outstanding precision, which allows for perfect perforations and micro perforations,” Gysbers explains.

In addition, Wink has further optimized its “ForceControl” pressure monitoring system for monitoring and adjusting cutting pressure, thus guaranteeing an effective and controlled process for all diecutting tasks. Explains Gysbers: “The pressure gauges can be easily positioned immediately after changing jobs using the quick snap lock system. ForceControl pressure gauges come in three different versions, each of them adapted to specific machine configurations and applications.”

Since it was founded in 1989, Wink has grown steadily. Gysbers concludes, “There are many points that make the ‘Wink difference.’ For example, all SuperCut dies have standard non-corrosion coating to prevent rust. All our dies are cut by laser, which not only guarantees perfectly parallel edges, but also minimizes the risk of injury. Finally, it’s our staff who sets us apart from the rest. Our claim ‘You cut, we care’ is not only a slogan, but a philosophy that every Wink employee puts into practice every day.”

Kocher + Beck

Germany-based rotary diecutting specialist Kocher + Beck continues to invest in new equipment and technology. “Our goal is to meet customers’ needs both today and in the future, as well as focusing on total continuous improvement to reduce waste and increase throughput throughout the production process,” says Daniel Grammatikos, chief financial officer for Kocher + Beck USA, the company’s North American divison based in Lenexa, KS.

Kocher + Beck continues to see increased sales and interest in its magnetic cylinders and flexible die products. Grammatikos says, “Customers cite the tight tolerances that these products offer in addition to the repeatability and predictability, resulting in profitability. Also, utilizing our technical support team for special applications is also cited as a powerful resource.”

According to Grammatikos, Kocher + Beck has several R&D projects in the works that are expected to launch this year. “Kocher + Beck offers unparalleled service to its customers and their customer projects, along with valued product offerings based upon run needs and substrates. Customer satisfaction on industry-leading tolerances is also cited as a reason our customers continue to place repeat and new orders with us.”

In addition to supplying a full range of diecutting and printing technology and tooling, the company supplies cutting stations such as the GapMaster, as well as automatic unwinding and rewinding systems. The GapMaster sets the gap between the stamping/magnetic cylinder and the counter-stamping cylinder in a rotation stamping system. The company’s UR Precision automatic unwinding and rewinding system ensures nonstop feeding and winding for web materials to the printing and converting machinery.

In addition, Kocher + Beck recently announced it now offers in-house production of its proprietary Tec Screens for rotary screen printing from its expanded manufacturing plant in Lenexa, KS, USA.

Wilson Manufacturing

St. Louis-based Wilson Manufacturing is a pioneer in the manufacture of machine-sharpened dies for the label converting industry. In order to better serve customers, it has invested in a new flexible die production facility, that is currently under construction. The new plant will be completed and fully operational by April 2018. “This facility will provide more than six times our current capacity, guaranteeing shorter lead times for our customers. It also includes additional R&D space along with new equipment in every department of the production process,” says Wade Fouts, vice president of sales for Wilson Manufacturing.

“Converters continue to pursue options with flexible cutting dies versus the traditional tools,” Fouts adds. “With this in mind, we offer faster delivery times and lower costs for the average converter. Our R&D team is focused on continuous improvement, bringing dies to the table that offer longer life spans and more flexibility for thin film substrates.”

Wilson Manufacturing prides itself on not only providing high quality, consistently, but also superior customer service. Fouts says, “Our technical support group and our quarterly technical tips periodical has become the backbone for our entire sales and marketing team.”

Fouts stresses that Wilson is not locked into any specific line of tooling. “Converters are often shocked when they present special applications that other die manufacturers said couldn’t be converted. We show the client the reasons it can be successful, not the reasons it cannot. Our outside-the-box thinking continues to drive new converters to our family every year,” he says, adding, “The members of the Wilson family – suppliers, customers and employees – are so focused on making sure your experience is everything you could wish for. Fast response times, superior technical support with a solution-focused mentality has separated our family from the others.”

The evolution of this sector of the industry places strong emphasis on the supplier. With flexible dies, delivery and turnaround time are more important to converters than ever before. Also, die suppliers must take note of evolving print and substrate technologies such as the proliferation of digital printing and the move toward thinner materials.

L&NW recently caught up with the industry’s leading rotary diecutting specialists, who filled us in on new products and technologies, what they see as the key label industry trends, and the role they’re playing in influencing the diecutting sector of the market. And within the die and diecutting space, the following suppliers also share what sets them apart, as well as the advantages their products and services provide.

RotoMetrics

One of the more noteworthy M&A news stories from 2017 was RotoMetrics’ acquisition of flexible die specialist Electro Optic. The move underscores the prominent role flexible dies are now playing in the industry.

“As an integral part of the converting process, we want to help our customers get more business,” says Keith Laako, RotoMetrics’ VP of global marketing and business development. “We understand there is a growing demand in the market for unique packaging solutions and an increasing need for speed and efficiency. That is exactly why we brought together the two best tooling companies. Our combined operations offer the most innovative diecutting technology, plus the broadest product range in the market to offer customized solutions for every converting challenge.”

Laako stresses that by joining forces with Electro Optic, RotoMetrics now offers what he says is the industry’s most extensive materials database. “We know how to cut materials better. We build our products to meet and exceed our customers’ standards for precision, sharpness and longevity. We are continually evolving our products and practices to deliver better solutions. Plus, we make house calls for on-site problem solving in the places where our customers do business to make sure we understand their challenges.

“Labels are a business built on speed,” he adds. “We built our business to be fast and responsive to our customers’ needs. We use state-of-the-art technology to deliver optimum performance with speed that exceeds industry standards. Our streamlined supply chain precisely delivers what you need, where and when you need it. Combine all this with our uncompromising regard for deadlines and we deliver what we promised, when we promised it.”

Among the new products RotoMetrics’ customers are benefitting from include dies that have new RotoRepel No-Stick Treatment, which is designed to solve the toughest adhesive challenges. Available on solid (new and resharpened) and flexible dies, RotoRepel features an exclusive technology and formulation that minimizes adhesive pick-up and transfer. RotoRepel is now available globally.

RotoRepel has many advantages over current industry non-stick offerings, Laako says, noting it is ultra-thin and won’t chip or flake. Blade profiles remain precise even after treatment with RotoRepel as there is no coating buildup. Additionally, dies treated with RotoRepel will run longer before any adhesive build-up occurs. If there is any adhesive build-up, the dies easily wipe off. In most cases, dies are stored after use and can quickly go on press again without extensive cleaning. Overall, press setup and downtime are significantly reduced.

According to Butch Schomber, new product innovation manager for Rotometrics, “RotoRepel is the culmination of three years of extensive R&D, and we actually have a non-stick that really works on almost all adhesives. After months of field trials with both converters and material suppliers, RotoRepel continues to receive unprecedented feedback. Our test trial customers love RotoRepel. Not only is it allowing operators to run longer between die cleanings, it almost eliminates adhesive whip and drastically reduces label lift and contaminated product. Due to less die handling, our customers are also reporting a major drop in die damage caused in the cleaning process.”

On the Electro Optic side of the business, RotoMetrics offers the Gold Line Special flexible die that features no liner strike and what the company says is unmatched height parallelism due to Electro Optic’s patented processes. “New label materials create increasingly special demands on the precision of all components involved in diecutting. Successful diecutting on ultra-thin liners without die strike can only be accomplished by keeping the tolerances within the narrowest limits. Electro Optic’s Gold Line Special quality exactly meets this challenge,” Laako says.

Also popular among label converters within the Electro Optic product portfolio is the Dura Line flexible die, which is specifically designed to handle the most abrasive materials for longer die life and longer production runs. The company says Electro Optic’s manufacturing processes produce dies with considerable extra life compared to standard flexible dies on the most demanding materials, including abrasive papers, thermal papers, recycled papers and thin cardboard.

Electro Optic’s Dura Line coating provides surface hardness of more than 1,100 HV (in comparison: The laser hardening until 63 HRC ≈ 800 HV) protects the cutting lines against scrubbing of high gloss paper, thermal paper, matted foils, writeable colors and lacquers, luminescence inks, metallic inks, whitener and pastel colors.

With manufacturing support services on five continents, RotoMetrics and Electro Optic offer broad global distribution of precision tooling. The combined strengths of the two organizations allow for more products, to more people, in more places. Concludes Laako, “We believe our unique combination of exceptional people providing unparalleled support and reliable solutions create value and speed that are key to helping our customers succeed.”

Wink

Wink is a Germany-based diecutting specialist that operates under the mantra, “You cut, we care.” The company’s North American outpost, Wink US, LLC, is based in Charlotte, NC. In reviewing the state of the industry, Andre Gysbers, marketing director at Wink, says, “The most obvious trends are digitalization and automation, which of course have an impact on all industries. To maximize efficiency and productivity, label converters are searching for potential improvements along the whole value chain. While much of the developments focus on printing, the finishing process has become increasingly more crucial.”

Wink has addressed evolving finishing needs by developing a new version of its SmartGap anvil adjustable system, which is designed to fit perfectly into new automated environments. With SmartGap, the cylinder gap (clearance) can be adapted very precisely to different liners and fluctuating liner thicknesses, so that even with demanding applications and very thin liners, optimum diecutting results are achieved.

“The SmartGap system is very simple and flexible to operate,” Gysbers explains. “The operator can adapt the gap with greatest accuracy individually for the drive and operator side. Because the cutting depth does not have to be regulated via the pretension, the service life of the tools is increased at the same time. In contrast to other adjustable systems, the SmartGap does not have any limitations. The system even makes cutting-through (metal-to-metal) possible without any problems and results in extremely low-maintenance. With the ongoing shift towards more sophisticated labels and special applications that require high precision diecutting for extremely thin liner material, flawless diecutting on these liners is only possible using tooling such as our SmartGap adjustable anvil SuperCut “Special” dies with minimum tolerances.”

Supercut features Wink’s CNC-made flexible dies that take into account specific adjustments of the blade geometry for perfect diecutting of difficult materials and applications with very intricate shapes. The company also leverages its die coatings expertise to meet customer needs. Gysbers says, “We offer a unique range of finishing and coatings to maximize diecutting efficiency. Among these are our MCR “MicroChrome” coating, MC plus coating, laser hardening and four different non-stick coatings that provide long lifetimes even when used to cut abrasive labelstock or extreme adhesives.”

For 2018, Wink is planning the launch of the SmartGap “Touch.” The patent-pending system offers numerous smart functions, which lead increased in efficiencies with regard to the automation of production processes. Moreover, the new technology allows for gap adjustment steps of only half a micron. Upcoming feature packages will include job control functions, automatic gap control and MIS connectivity.

Wink recently launched the PerfoPlus line of flexible dies. “Many label and packaging applications include some kind of perforation in a variety of designs. Quite often, these perforations are difficult to achieve with conventionally produced flexible dies. Our new PerfoPlus flexible dies overcome these challenges. With patent-pending laser technology, the perforation cuts and ties are produced with outstanding precision, which allows for perfect perforations and micro perforations,” Gysbers explains.

In addition, Wink has further optimized its “ForceControl” pressure monitoring system for monitoring and adjusting cutting pressure, thus guaranteeing an effective and controlled process for all diecutting tasks. Explains Gysbers: “The pressure gauges can be easily positioned immediately after changing jobs using the quick snap lock system. ForceControl pressure gauges come in three different versions, each of them adapted to specific machine configurations and applications.”

Since it was founded in 1989, Wink has grown steadily. Gysbers concludes, “There are many points that make the ‘Wink difference.’ For example, all SuperCut dies have standard non-corrosion coating to prevent rust. All our dies are cut by laser, which not only guarantees perfectly parallel edges, but also minimizes the risk of injury. Finally, it’s our staff who sets us apart from the rest. Our claim ‘You cut, we care’ is not only a slogan, but a philosophy that every Wink employee puts into practice every day.”

Kocher + Beck

Germany-based rotary diecutting specialist Kocher + Beck continues to invest in new equipment and technology. “Our goal is to meet customers’ needs both today and in the future, as well as focusing on total continuous improvement to reduce waste and increase throughput throughout the production process,” says Daniel Grammatikos, chief financial officer for Kocher + Beck USA, the company’s North American divison based in Lenexa, KS.

Kocher + Beck continues to see increased sales and interest in its magnetic cylinders and flexible die products. Grammatikos says, “Customers cite the tight tolerances that these products offer in addition to the repeatability and predictability, resulting in profitability. Also, utilizing our technical support team for special applications is also cited as a powerful resource.”

According to Grammatikos, Kocher + Beck has several R&D projects in the works that are expected to launch this year. “Kocher + Beck offers unparalleled service to its customers and their customer projects, along with valued product offerings based upon run needs and substrates. Customer satisfaction on industry-leading tolerances is also cited as a reason our customers continue to place repeat and new orders with us.”

In addition to supplying a full range of diecutting and printing technology and tooling, the company supplies cutting stations such as the GapMaster, as well as automatic unwinding and rewinding systems. The GapMaster sets the gap between the stamping/magnetic cylinder and the counter-stamping cylinder in a rotation stamping system. The company’s UR Precision automatic unwinding and rewinding system ensures nonstop feeding and winding for web materials to the printing and converting machinery.

In addition, Kocher + Beck recently announced it now offers in-house production of its proprietary Tec Screens for rotary screen printing from its expanded manufacturing plant in Lenexa, KS, USA.

Wilson Manufacturing

St. Louis-based Wilson Manufacturing is a pioneer in the manufacture of machine-sharpened dies for the label converting industry. In order to better serve customers, it has invested in a new flexible die production facility, that is currently under construction. The new plant will be completed and fully operational by April 2018. “This facility will provide more than six times our current capacity, guaranteeing shorter lead times for our customers. It also includes additional R&D space along with new equipment in every department of the production process,” says Wade Fouts, vice president of sales for Wilson Manufacturing.

“Converters continue to pursue options with flexible cutting dies versus the traditional tools,” Fouts adds. “With this in mind, we offer faster delivery times and lower costs for the average converter. Our R&D team is focused on continuous improvement, bringing dies to the table that offer longer life spans and more flexibility for thin film substrates.”

Wilson Manufacturing prides itself on not only providing high quality, consistently, but also superior customer service. Fouts says, “Our technical support group and our quarterly technical tips periodical has become the backbone for our entire sales and marketing team.”

Fouts stresses that Wilson is not locked into any specific line of tooling. “Converters are often shocked when they present special applications that other die manufacturers said couldn’t be converted. We show the client the reasons it can be successful, not the reasons it cannot. Our outside-the-box thinking continues to drive new converters to our family every year,” he says, adding, “The members of the Wilson family – suppliers, customers and employees – are so focused on making sure your experience is everything you could wish for. Fast response times, superior technical support with a solution-focused mentality has separated our family from the others.”