Greg Hrinya, Associate Editor07.13.18

For the average consumer, it is easy to miss all the vital steps that go into producing a high-quality label. While the graphics stand out on the shelf, there are a plethora of processes that facilitate label printing. Doctor blades are one of the most important components to labels and packaging production, yet they are often overlooked.

Consistency and repeatability have emerged as the holy grail of label printing. It’s not enough for a converter to produce a stunning label once; they must be able to replicate that label every time. Doctor blades play a key role in flexographic printing, which, despite the inroads made by digital, still accounts for roughly 90% of printed labels.

“With all of the components involved in the flexo printing process, the doctor blade can easily be overlooked and even appear to be a trivial component but, as often is the case, appearances can be deceiving,” explains Bill Warner, vice president of Allison Systems. “The best equipment, prepress and operating procedures cannot produce quality graphics if the doctor blade fails to perform consistently throughout the entire run.”

“Doctor blades are more important than people often think,” says Andrew Latosek, national account manager at Flexo Concepts. “The magic of flexo printing occurs when every aspect of the process is optimized. These small, consumable parts play an integral role in transferring an accurate amount of ink to the plate.”

A doctor blade allows converters to control ink film thickness, which can drastically affect a finished product. According to Dave DeMille, sales manager at Printco Industries, doctor blades provide a very accurate metering of the ink on the roll. Having the right doctor blade provides many benefits, including the prevention of dot gain, dirty print, ink flooding, uneven coverage, accelerated blade wear and UV ink spitting, among others.

Henrik Kristensen, vice president at Tresu Ancillary, a division of Tresu Group, also notes that doctor blades act as a barrier to prevent air from contaminating the ink, as well as leakage. “The doctor blade maintains a wall of ink between the blade and the anilox to ensure desired levels of coverage,” he says. “Correct positioning of the blade is essential: if it’s positioned too close to the anilox roll, or at the wrong angle, it will accelerate wear of both the blade and the anilox.”

The technology has undoubtedly improved, leading to better print quality. “Without the technological advancements in doctor blades in the past 30 years, the printer would not be able to control ink film thickness,” explains Johnny Stamey, technical product manager at Daetwyler. “When you can’t control that part of the process, your print quality will always have variations, and in today’s competitive market your process must be predicable and repeatable without compromise to customers’ standards.”

Stamey also notes that doctor blades are often the problem when troubleshooting quality issues on press. However, printers look toward plates, tapes and inks when a simple doctor blade change would clean up a dot gain issue or other color variation problems.

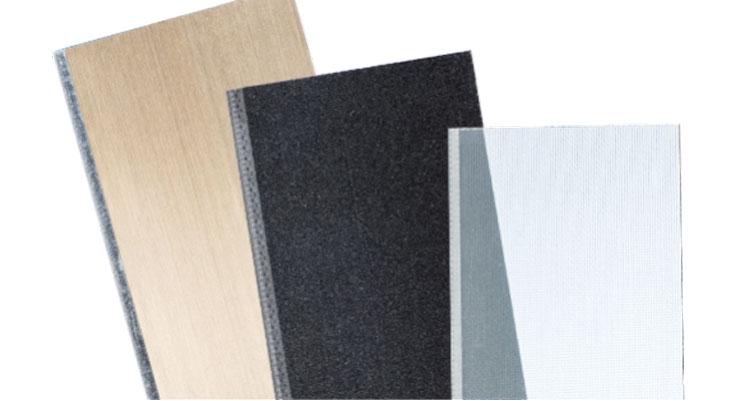

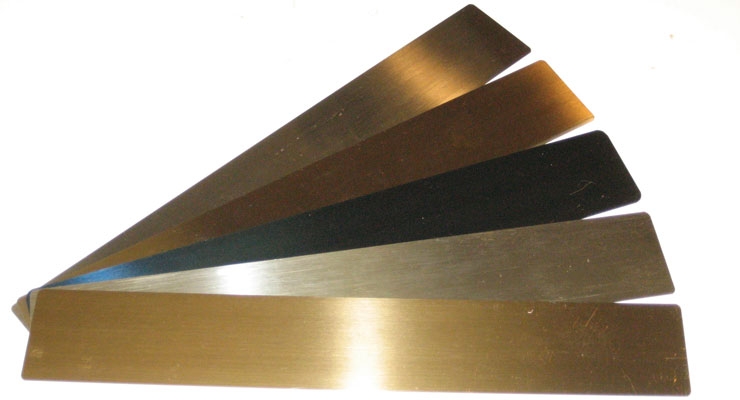

Today, most doctor blades utilize white carbon steel (WCS). This will include different tip configurations, such as lamella tips, bevels or round/radius tips, while the remainder of the product is composed of WCS. There are multiple benefits of using this material, including added chromium for extended life, various coated blades, stainless steel, alloy and tool steel blades that would fall close to the same percentage of usage.

According to All Printing Resources’ Technical Solutions Group, steel is typically the most popular blade material and often the go-to choice due to general comfort level. “Steel offers a wider breadth of steel material options, coatings and tip configurations at a variety of price points,” the company says. “Synthetic blades can offer the same quality and longevity benefits of steel with the added advantages of safety and minimizing the chance to damage the anilox or contaminate ink with metal particles.”

Proper setup and an experienced pressman to use the blades correctly will lead to longer blade life and a more efficient process. Various materials fall along different spots on the print spectrum. For example, plastic and steel could be used in conjunction in enclosed chamber systems, where steel blades perform metering while plastic operates as a containment blade. Steel blades offer finely-machined, precise tips that are capable of wiping the anilox roller cleaner for longer periods of time. They are traditionally more consistent and predictable than plastic.

“To make a machined tip on plastic, you must increase the tip thickness to 200 microns,” says Stamey. “This causes the contact area to become very large against the anilox roller and you cannot control your ink film thickness on the higher fine line screen rollers. You tend to transfer too much ink to the plate in this situation which can cause color variations and dot gain.”

It is important to note, however, that most plastic blades maintain a long life and are acceptable on lower line screen anilox rollers and plates where the print features more line work and solids.

There are other benefits to plastic, as well. “Plastic materials are inherently softer and not as sharp as steel, and plastic doctor blades are not dangerous when being removed from the press,” says Latosek. “The blades are also self-lubricating and have a lower coefficient of friction than steel, which makes them last longer and safer for anilox rolls.”

DeMille notes that Printco provides an equal amount of steel and plastic blades to its customers. “It’s really a preference and what works best for the application,” he says. “We have customers running blades up to three weeks.”

For converters, choosing the right doctor blade is not a one-size-fits-all proposition. Multiple factors come into play, including the press model and the age of equipment, ink type, anilox line count, substrate, press speeds, holder type – single blade or enclosed chamber, as well as others.

“Every pressroom is different,” says Stamey. “Being a manufacturer allows us to work with the printer and help design, if needed, a special blade just for their pressroom. We do extensive research on different market segments throughout the year by talking to the printers, this way we can find out what the current issues are and address them as they arise.”

Converters can enjoy personalized solutions for their workflow, too. “Working with your blade supplier, they can help to narrow down all the options to a few key recommendations based on your variables, needs and expectations,” APR’s Technical Solution Group states. “They can then work through a blade trial process to determine which blades meet desired quality and performance standards. Blade optimization is a critical step in challenging and improving overall print quality and press room efficiencies.”

Doctor Blade Evolution

According to Daetwyler’s Stamey, doctor blades have undergone “tremendous” change over the past 7-10 years. In fact, following the invention of the lamella tip in the 1970s, doctor blades would go quite some time without any major modifications.

“Coated or special material steel blades are now available for extended blade life while plastic blade materials are improving with more material and edge options,” explains Printco’s DeMille.

The constant growth in the labels and packaging sector has necessitated enhancements to doctor blades. Modern blades produce cleaner, sharper images to meet demand for the best print quality.

“The graphic demands of the print buyer for better shelf appeal to the consumer has driven the entire flexo process to get better,” says Stamey. “These changes have been the driving factor behind the new generation of coated blades.”

Luckily, there are more products available than ever before to meet the needs of each individual converter. Printers often face conflicting requirements, and Flexo Concepts says the greatest challenge facing suppliers revolves around solutions to remedy those issues.

According to Flexo Concepts’ Latosek, the greatest changes relate to the number and types of blade materials. “In particular, plastic materials have advanced at a rapid rate, with the performance of some new polymers now capable of matching the metering ability of steel,” he says.

“Blade material, blade thickness and blade tip thickness can all be tailored for a specific job or to resolve a specific problem such as too much ink left on the anilox roll,” adds Latosek. “A thicker blade material will provide enhanced rigidity and stability while a thicker blade tip will last longer. A beveled edge may last longer on applications that utilize a heavier ink laydown on a low line screen/higher BCM roll, whereas a small MicroTip will deliver more precise and consistent metering on high line screen/lower BCM rolls.”

In the future, Daetwyler can envision further improvement. This could include new coatings for every aspect of printing, as well as new tip configurations. Allison Systems, meanwhile, sees potential enhancements that include different materials, performance enhancing coatings and edge shapes.

Troubleshooting Problems

There are several inherent challenges and dangers when working with doctor blades. From a challenges perspective, press operators must remain diligent in changing doctor blades at the correct time.

As other equipment and consumables evolve in the printing industry, there is a direct impact on all parts of the process. Doctor blades are no exception. “Inks and anilox rolls are constantly changing and generally becoming more abrasive to the doctor blade,” says Allison Systems’ Warner. “Advancements in press speeds are also contributing to blade wear. The demand for better print quality necessitates that the doctor blade perform better and more consistently.”

Warner adds that a potential remedy to this problem includes long life steel blades, as they offer excellent results with abrasive inks, such as white inks or other inks with high percentages of titanium dioxide or solids and/or rough anilox rolls. Long life steels are typically made from tool steel alloys that offer good resistance to adhesive and abrasive wear.

According to Daetwyler, companies will often replace blades prematurely, before they reach their “end of life” status. A blade analysis will reveal that a number of changed blades were perfectly acceptable at the time in which they were removed. Some companies have instilled procedures whereby they will change a blade at a predetermined time, regardless of its condition. The replacement could occur with every new job or at a specific time on press.

Operator training is critical, too. Warner adds that it costs significantly more to stop a press and change the doctor blade than the actual cost of the blade. Training helps establish standard operating procedures, ensuring proper blade application, as well as the ability to choose the best blade for a specific application.

In terms of dangers, doctor blades are obviously sharp instruments that must be handled properly. Handling used blades requires cut resistant or cut-proof gloves. Pressrooms should all establish safety guidelines for the proper handling and disposal of all used doctor blades.

APR’s Technical Solutions Group cites safety as a reason many converters will shift toward synthetic blades, but the increased quality provides an added benefit. “Synthetic blades are typically a first thought for safety but can actually rival the quality and longevity expected from steel,” says APR. “In fact, informed printers have learned that some of the current synthetic materials can even offer longer life over steel and still provide the same safety and quality benefits without the potential of damaging the anilox.”

Even though plastic blades exist, it is important to note that there is still a risk. “It is often assumed that a plastic blade will not get sharp enough to cause cut injuries,” says Warner. “However, that is not the case, and it is strongly recommended to use cut resistant gloves and follow plant safety procedures when handling all doctor blades.”

(For more information on plant safety, check out our feature article on page 84 of this issue.)

Product Variety

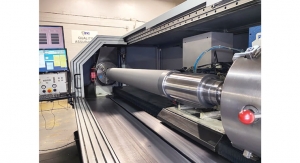

Doctor blade manufacturers offer a host of products to help converters. For the narrow web market, Daetwyler has designed several products to handle UV ink spitting, cleaner print and longer anilox roller life. The company recently released PearlStar, which has a non-stick coating for UV ink spitting, and the MDC – Multiflex, which offers a special steel with a hybrid tip design that is optimized for UV inks with the added benefit of longer blade life.

In 2017, Daetwyler launched GamutStar, the second of its new generation of multi-layered coated blades. This blade has a soft nickel coating on the outside to help protect the anilox roller, while underneath a wear resistant coating adds life to the doctor blade.

APR offers a variety of steel and synthetic blade solutions, and the company prides itself on working with customers individually to address their specific print production variables, as well as challenges and goals. “We are dedicated to keeping our customers informed on any new developments in blades,” the company says. “As our industry continues to advance and improve, the process for optimizing blades to determine the best fit will evolve.”

Allison Systems provides its customers with more than just blades, it offers services and packaging solutions for its materials, as well. As far as blades go, the company offers White (CX), which is the most common carbon steel blade material. It features high-quality steel with economical life and excellent metallurgical properties.

“Our material selection includes various forms of steel, composites and plastics so that we can provide to our customers a material that works best for their specific application and goals,” explains Warner.

Meanwhile, Printco provides a product range offering mild steel, stainless steel, long-life coated steel blades and many different plastic blades in a variety of tips and widths. Blades can be ordered cut to length or in roll form, as well.

Tresu offers stainless steel and plastic doctor blades in rolls of 100 meters. Rolls of stainless steel doctor blades are available in 35mm or 45mm length and 0.13mm thickness. Tresu also offers a program of chamber doctor blades in aluminum, carbon fiber and ceramic varieties. SAVEink chamber features Tresu’s seal system and E-Line quick-blade change system, as well.

Flexo Concepts has engineered the TruPoint Orange doctor blade. The blade can achieve and maintain a fine contact area with the anilox roll and rival the performance of steel, metering line screens up to 2000 lpi (785 L/cm). Its long and steady wear period maximizes press uptime and allows for consistent ink film thickness.

TruPoint Orange is compatible with all UV inks and special coating formulas. The properties of the Orange material give the blade a significantly lower dyne level than steel, decreasing the attraction between the doctor blade and ink to facilitate a more fluid movement of ink to the plate.

Consistency and repeatability have emerged as the holy grail of label printing. It’s not enough for a converter to produce a stunning label once; they must be able to replicate that label every time. Doctor blades play a key role in flexographic printing, which, despite the inroads made by digital, still accounts for roughly 90% of printed labels.

“With all of the components involved in the flexo printing process, the doctor blade can easily be overlooked and even appear to be a trivial component but, as often is the case, appearances can be deceiving,” explains Bill Warner, vice president of Allison Systems. “The best equipment, prepress and operating procedures cannot produce quality graphics if the doctor blade fails to perform consistently throughout the entire run.”

“Doctor blades are more important than people often think,” says Andrew Latosek, national account manager at Flexo Concepts. “The magic of flexo printing occurs when every aspect of the process is optimized. These small, consumable parts play an integral role in transferring an accurate amount of ink to the plate.”

A doctor blade allows converters to control ink film thickness, which can drastically affect a finished product. According to Dave DeMille, sales manager at Printco Industries, doctor blades provide a very accurate metering of the ink on the roll. Having the right doctor blade provides many benefits, including the prevention of dot gain, dirty print, ink flooding, uneven coverage, accelerated blade wear and UV ink spitting, among others.

Henrik Kristensen, vice president at Tresu Ancillary, a division of Tresu Group, also notes that doctor blades act as a barrier to prevent air from contaminating the ink, as well as leakage. “The doctor blade maintains a wall of ink between the blade and the anilox to ensure desired levels of coverage,” he says. “Correct positioning of the blade is essential: if it’s positioned too close to the anilox roll, or at the wrong angle, it will accelerate wear of both the blade and the anilox.”

The technology has undoubtedly improved, leading to better print quality. “Without the technological advancements in doctor blades in the past 30 years, the printer would not be able to control ink film thickness,” explains Johnny Stamey, technical product manager at Daetwyler. “When you can’t control that part of the process, your print quality will always have variations, and in today’s competitive market your process must be predicable and repeatable without compromise to customers’ standards.”

Stamey also notes that doctor blades are often the problem when troubleshooting quality issues on press. However, printers look toward plates, tapes and inks when a simple doctor blade change would clean up a dot gain issue or other color variation problems.

Today, most doctor blades utilize white carbon steel (WCS). This will include different tip configurations, such as lamella tips, bevels or round/radius tips, while the remainder of the product is composed of WCS. There are multiple benefits of using this material, including added chromium for extended life, various coated blades, stainless steel, alloy and tool steel blades that would fall close to the same percentage of usage.

According to All Printing Resources’ Technical Solutions Group, steel is typically the most popular blade material and often the go-to choice due to general comfort level. “Steel offers a wider breadth of steel material options, coatings and tip configurations at a variety of price points,” the company says. “Synthetic blades can offer the same quality and longevity benefits of steel with the added advantages of safety and minimizing the chance to damage the anilox or contaminate ink with metal particles.”

Proper setup and an experienced pressman to use the blades correctly will lead to longer blade life and a more efficient process. Various materials fall along different spots on the print spectrum. For example, plastic and steel could be used in conjunction in enclosed chamber systems, where steel blades perform metering while plastic operates as a containment blade. Steel blades offer finely-machined, precise tips that are capable of wiping the anilox roller cleaner for longer periods of time. They are traditionally more consistent and predictable than plastic.

“To make a machined tip on plastic, you must increase the tip thickness to 200 microns,” says Stamey. “This causes the contact area to become very large against the anilox roller and you cannot control your ink film thickness on the higher fine line screen rollers. You tend to transfer too much ink to the plate in this situation which can cause color variations and dot gain.”

It is important to note, however, that most plastic blades maintain a long life and are acceptable on lower line screen anilox rollers and plates where the print features more line work and solids.

There are other benefits to plastic, as well. “Plastic materials are inherently softer and not as sharp as steel, and plastic doctor blades are not dangerous when being removed from the press,” says Latosek. “The blades are also self-lubricating and have a lower coefficient of friction than steel, which makes them last longer and safer for anilox rolls.”

DeMille notes that Printco provides an equal amount of steel and plastic blades to its customers. “It’s really a preference and what works best for the application,” he says. “We have customers running blades up to three weeks.”

For converters, choosing the right doctor blade is not a one-size-fits-all proposition. Multiple factors come into play, including the press model and the age of equipment, ink type, anilox line count, substrate, press speeds, holder type – single blade or enclosed chamber, as well as others.

“Every pressroom is different,” says Stamey. “Being a manufacturer allows us to work with the printer and help design, if needed, a special blade just for their pressroom. We do extensive research on different market segments throughout the year by talking to the printers, this way we can find out what the current issues are and address them as they arise.”

Converters can enjoy personalized solutions for their workflow, too. “Working with your blade supplier, they can help to narrow down all the options to a few key recommendations based on your variables, needs and expectations,” APR’s Technical Solution Group states. “They can then work through a blade trial process to determine which blades meet desired quality and performance standards. Blade optimization is a critical step in challenging and improving overall print quality and press room efficiencies.”

Doctor Blade Evolution

According to Daetwyler’s Stamey, doctor blades have undergone “tremendous” change over the past 7-10 years. In fact, following the invention of the lamella tip in the 1970s, doctor blades would go quite some time without any major modifications.

“Coated or special material steel blades are now available for extended blade life while plastic blade materials are improving with more material and edge options,” explains Printco’s DeMille.

The constant growth in the labels and packaging sector has necessitated enhancements to doctor blades. Modern blades produce cleaner, sharper images to meet demand for the best print quality.

“The graphic demands of the print buyer for better shelf appeal to the consumer has driven the entire flexo process to get better,” says Stamey. “These changes have been the driving factor behind the new generation of coated blades.”

Luckily, there are more products available than ever before to meet the needs of each individual converter. Printers often face conflicting requirements, and Flexo Concepts says the greatest challenge facing suppliers revolves around solutions to remedy those issues.

According to Flexo Concepts’ Latosek, the greatest changes relate to the number and types of blade materials. “In particular, plastic materials have advanced at a rapid rate, with the performance of some new polymers now capable of matching the metering ability of steel,” he says.

“Blade material, blade thickness and blade tip thickness can all be tailored for a specific job or to resolve a specific problem such as too much ink left on the anilox roll,” adds Latosek. “A thicker blade material will provide enhanced rigidity and stability while a thicker blade tip will last longer. A beveled edge may last longer on applications that utilize a heavier ink laydown on a low line screen/higher BCM roll, whereas a small MicroTip will deliver more precise and consistent metering on high line screen/lower BCM rolls.”

In the future, Daetwyler can envision further improvement. This could include new coatings for every aspect of printing, as well as new tip configurations. Allison Systems, meanwhile, sees potential enhancements that include different materials, performance enhancing coatings and edge shapes.

Troubleshooting Problems

There are several inherent challenges and dangers when working with doctor blades. From a challenges perspective, press operators must remain diligent in changing doctor blades at the correct time.

As other equipment and consumables evolve in the printing industry, there is a direct impact on all parts of the process. Doctor blades are no exception. “Inks and anilox rolls are constantly changing and generally becoming more abrasive to the doctor blade,” says Allison Systems’ Warner. “Advancements in press speeds are also contributing to blade wear. The demand for better print quality necessitates that the doctor blade perform better and more consistently.”

Warner adds that a potential remedy to this problem includes long life steel blades, as they offer excellent results with abrasive inks, such as white inks or other inks with high percentages of titanium dioxide or solids and/or rough anilox rolls. Long life steels are typically made from tool steel alloys that offer good resistance to adhesive and abrasive wear.

According to Daetwyler, companies will often replace blades prematurely, before they reach their “end of life” status. A blade analysis will reveal that a number of changed blades were perfectly acceptable at the time in which they were removed. Some companies have instilled procedures whereby they will change a blade at a predetermined time, regardless of its condition. The replacement could occur with every new job or at a specific time on press.

Operator training is critical, too. Warner adds that it costs significantly more to stop a press and change the doctor blade than the actual cost of the blade. Training helps establish standard operating procedures, ensuring proper blade application, as well as the ability to choose the best blade for a specific application.

In terms of dangers, doctor blades are obviously sharp instruments that must be handled properly. Handling used blades requires cut resistant or cut-proof gloves. Pressrooms should all establish safety guidelines for the proper handling and disposal of all used doctor blades.

APR’s Technical Solutions Group cites safety as a reason many converters will shift toward synthetic blades, but the increased quality provides an added benefit. “Synthetic blades are typically a first thought for safety but can actually rival the quality and longevity expected from steel,” says APR. “In fact, informed printers have learned that some of the current synthetic materials can even offer longer life over steel and still provide the same safety and quality benefits without the potential of damaging the anilox.”

Even though plastic blades exist, it is important to note that there is still a risk. “It is often assumed that a plastic blade will not get sharp enough to cause cut injuries,” says Warner. “However, that is not the case, and it is strongly recommended to use cut resistant gloves and follow plant safety procedures when handling all doctor blades.”

(For more information on plant safety, check out our feature article on page 84 of this issue.)

Product Variety

Doctor blade manufacturers offer a host of products to help converters. For the narrow web market, Daetwyler has designed several products to handle UV ink spitting, cleaner print and longer anilox roller life. The company recently released PearlStar, which has a non-stick coating for UV ink spitting, and the MDC – Multiflex, which offers a special steel with a hybrid tip design that is optimized for UV inks with the added benefit of longer blade life.

In 2017, Daetwyler launched GamutStar, the second of its new generation of multi-layered coated blades. This blade has a soft nickel coating on the outside to help protect the anilox roller, while underneath a wear resistant coating adds life to the doctor blade.

APR offers a variety of steel and synthetic blade solutions, and the company prides itself on working with customers individually to address their specific print production variables, as well as challenges and goals. “We are dedicated to keeping our customers informed on any new developments in blades,” the company says. “As our industry continues to advance and improve, the process for optimizing blades to determine the best fit will evolve.”

Allison Systems provides its customers with more than just blades, it offers services and packaging solutions for its materials, as well. As far as blades go, the company offers White (CX), which is the most common carbon steel blade material. It features high-quality steel with economical life and excellent metallurgical properties.

“Our material selection includes various forms of steel, composites and plastics so that we can provide to our customers a material that works best for their specific application and goals,” explains Warner.

Meanwhile, Printco provides a product range offering mild steel, stainless steel, long-life coated steel blades and many different plastic blades in a variety of tips and widths. Blades can be ordered cut to length or in roll form, as well.

Tresu offers stainless steel and plastic doctor blades in rolls of 100 meters. Rolls of stainless steel doctor blades are available in 35mm or 45mm length and 0.13mm thickness. Tresu also offers a program of chamber doctor blades in aluminum, carbon fiber and ceramic varieties. SAVEink chamber features Tresu’s seal system and E-Line quick-blade change system, as well.

Flexo Concepts has engineered the TruPoint Orange doctor blade. The blade can achieve and maintain a fine contact area with the anilox roll and rival the performance of steel, metering line screens up to 2000 lpi (785 L/cm). Its long and steady wear period maximizes press uptime and allows for consistent ink film thickness.

TruPoint Orange is compatible with all UV inks and special coating formulas. The properties of the Orange material give the blade a significantly lower dyne level than steel, decreasing the attraction between the doctor blade and ink to facilitate a more fluid movement of ink to the plate.