Greg Hrinya, Associate Editor10.11.19

Orion Labels

www.orionlabels.com

Orion Labels, a pressure sensitive label converter based in Seymour, WI, USA, is planning to take the next step in the labels and packaging industry. According to Eric August, partner at Orion Labels, the company’s latest acquisition has the business “poised for greatness.”

Orion Labels’ story began in 2004, when August and partner Neil Vandenberg founded the company. At the time, the two partners maintained more than 35 years of collective experience, but they began their journey with just four employees. Both men hailed from larger companies and were second-generation printers. However, they wanted to create their own path. They chose Wisconsin to do so.

“Eric raised his family 10 miles from Seymour, WI, and both of his children attended school there,” says Jonny August, director of operations at Orion Labels. “Knowing the values of the town, Eric and Neil decided this was the perfect place to start their business.”

Jonny is part of the leadership team at Orion Labels, and brings a tremendous amount of experience to the role as a third-generation printer. “The transition from second to third generation has been an incredible experience as we continue to invest in cutting-edge technology,” notes Jonny.

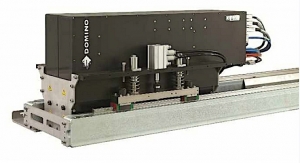

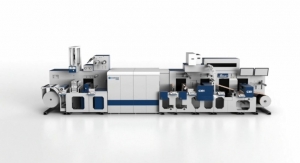

A majority of the converter’s business is pressure sensitive and roll-fed labels supplied to the food and beverage markets. Orion Labels also boasts a number of UL product offerings. Recently, the company installed a CEI BossJet powered by Domino hybrid press. Orion Labels got its start with traditional flexo printing, but in looking for a means to differentiate, the BossJet was the solution. The company already had experience working with CEI, making the acquisition that much more seamless.

“The BossJet offers us the ability to run multiple SKUs without the need to stop,” says Jonny. “With the addition of CEI’s flexo stations, we can run metallic tints, cold foils, and any brand of specific spot colors our customers need us to match. We can also do pattern varnishes. This allows us to create labels that allow our customers to differentiate themselves on the shelf. Some of the segments we target are craft breweries, wineries, cheese products and candies.”

Like many label converters in recent years, Orion realized it would need a digital solution to handle the short run work emerging in various markets – especially craft beer and food and beverage.

“We began to notice a segment of business for which we could no longer compete without digital,” notes Jonny. “Conversion costs were too high relative to the volume of labels, so high SKU projects were starting to become out of reach. We also identified a significant chunk of existing business that would essentially plug-and-play on the BossJet. The decision was made to open opportunities for new business, to run existing business more efficiently.”

The BossJet has allowed Orion Labels to significantly cut production times, as the company no longer needs to stop for plate or color changes. Orion Labels can now service customers in a fraction of the time. The new hybrid press features flexo and digital UV inkjet printing capabilities.

“Once we started comparing them to other digital engines out there, it was just a no-brainer for us,” states Eric. “It’s gotten to the point where people want to run this piece of equipment because it’s new and it’s exciting.”

In addition, both CEI and Domino were instrumental in getting the press up and running. “The support has been fantastic,” says Jonny. “Our operators were down training with Domino for a week and then had on-site training with CEI. Both operators really took to the training and quickly became confident running the machine. We have one operator with over 20 years of flexo printing experience and another operator with no previous printing experience.”

“We’ve noticed a definite difference to the bottom line because of the Domino and because of the CEI equipment,” says Vandenberg. “We’re running things in a much more efficient and cost-conscious way, and that’s huge for our customers.”

A common myth in the labels and packaging space is that digital and flexo are foes. On the contrary, Orion Labels has proven that the two technologies can successfully co-exist.

“The BossJet has opened lots of doors for us in terms of new business,” says Jonny. “In addition to this, however, it has allowed us to free up capacity on our flexo presses, which still remain a big focus for us. This freeing up of capacity allows us to target projects that fit our strategic goals. Our plan for the future is to continue to grow our digital footprint while continuing to invest in state of the art flexo equipment.”

Orion Labels has a history of providing excellent customer service. The company has been recognized by JJ Keller as a Vendor of the Year. In order to receive the award, a company must demonstrate excellence in quality, professionalism, value added, communication, resourcefulness, and service. Orion Labels has also been acknowledged for its manufacturing policies, as the company completed an NSF Audit in 2016 with a score of 99%. The audit ensures that all employees are educated on shared responsibilities and the inter-connectedness of all functions inside and outside the plant.

“We work with our customers to push the boundaries,” Jonny adds. “They know they can come to us with out of the box ideas and trust that we will put in the time to make it a reality. We pride ourselves on being problem solvers.”

www.orionlabels.com

Orion Labels, a pressure sensitive label converter based in Seymour, WI, USA, is planning to take the next step in the labels and packaging industry. According to Eric August, partner at Orion Labels, the company’s latest acquisition has the business “poised for greatness.”

Orion Labels’ story began in 2004, when August and partner Neil Vandenberg founded the company. At the time, the two partners maintained more than 35 years of collective experience, but they began their journey with just four employees. Both men hailed from larger companies and were second-generation printers. However, they wanted to create their own path. They chose Wisconsin to do so.

“Eric raised his family 10 miles from Seymour, WI, and both of his children attended school there,” says Jonny August, director of operations at Orion Labels. “Knowing the values of the town, Eric and Neil decided this was the perfect place to start their business.”

Jonny is part of the leadership team at Orion Labels, and brings a tremendous amount of experience to the role as a third-generation printer. “The transition from second to third generation has been an incredible experience as we continue to invest in cutting-edge technology,” notes Jonny.

A majority of the converter’s business is pressure sensitive and roll-fed labels supplied to the food and beverage markets. Orion Labels also boasts a number of UL product offerings. Recently, the company installed a CEI BossJet powered by Domino hybrid press. Orion Labels got its start with traditional flexo printing, but in looking for a means to differentiate, the BossJet was the solution. The company already had experience working with CEI, making the acquisition that much more seamless.

“The BossJet offers us the ability to run multiple SKUs without the need to stop,” says Jonny. “With the addition of CEI’s flexo stations, we can run metallic tints, cold foils, and any brand of specific spot colors our customers need us to match. We can also do pattern varnishes. This allows us to create labels that allow our customers to differentiate themselves on the shelf. Some of the segments we target are craft breweries, wineries, cheese products and candies.”

Like many label converters in recent years, Orion realized it would need a digital solution to handle the short run work emerging in various markets – especially craft beer and food and beverage.

“We began to notice a segment of business for which we could no longer compete without digital,” notes Jonny. “Conversion costs were too high relative to the volume of labels, so high SKU projects were starting to become out of reach. We also identified a significant chunk of existing business that would essentially plug-and-play on the BossJet. The decision was made to open opportunities for new business, to run existing business more efficiently.”

The BossJet has allowed Orion Labels to significantly cut production times, as the company no longer needs to stop for plate or color changes. Orion Labels can now service customers in a fraction of the time. The new hybrid press features flexo and digital UV inkjet printing capabilities.

“Once we started comparing them to other digital engines out there, it was just a no-brainer for us,” states Eric. “It’s gotten to the point where people want to run this piece of equipment because it’s new and it’s exciting.”

In addition, both CEI and Domino were instrumental in getting the press up and running. “The support has been fantastic,” says Jonny. “Our operators were down training with Domino for a week and then had on-site training with CEI. Both operators really took to the training and quickly became confident running the machine. We have one operator with over 20 years of flexo printing experience and another operator with no previous printing experience.”

“We’ve noticed a definite difference to the bottom line because of the Domino and because of the CEI equipment,” says Vandenberg. “We’re running things in a much more efficient and cost-conscious way, and that’s huge for our customers.”

A common myth in the labels and packaging space is that digital and flexo are foes. On the contrary, Orion Labels has proven that the two technologies can successfully co-exist.

“The BossJet has opened lots of doors for us in terms of new business,” says Jonny. “In addition to this, however, it has allowed us to free up capacity on our flexo presses, which still remain a big focus for us. This freeing up of capacity allows us to target projects that fit our strategic goals. Our plan for the future is to continue to grow our digital footprint while continuing to invest in state of the art flexo equipment.”

Orion Labels has a history of providing excellent customer service. The company has been recognized by JJ Keller as a Vendor of the Year. In order to receive the award, a company must demonstrate excellence in quality, professionalism, value added, communication, resourcefulness, and service. Orion Labels has also been acknowledged for its manufacturing policies, as the company completed an NSF Audit in 2016 with a score of 99%. The audit ensures that all employees are educated on shared responsibilities and the inter-connectedness of all functions inside and outside the plant.

“We work with our customers to push the boundaries,” Jonny adds. “They know they can come to us with out of the box ideas and trust that we will put in the time to make it a reality. We pride ourselves on being problem solvers.”