Steve Katz, Editor11.15.19

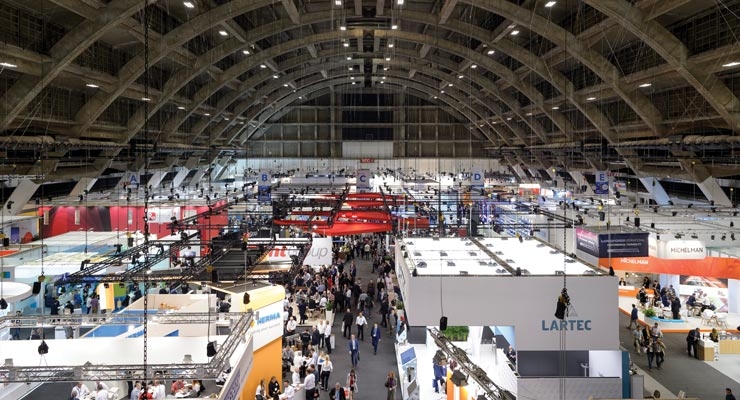

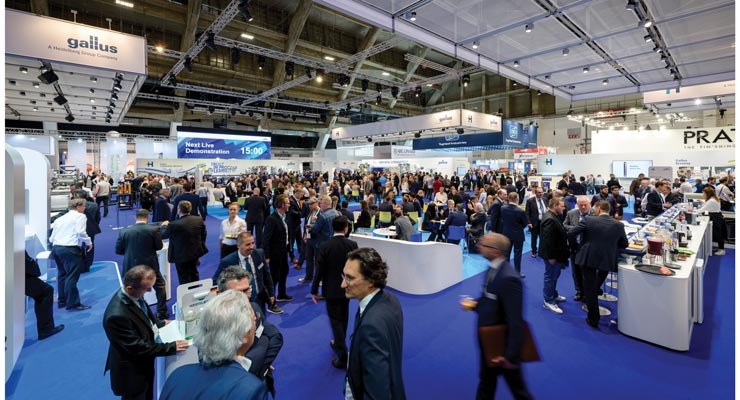

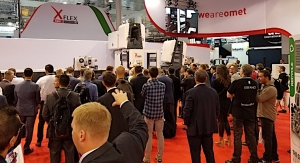

The 40th anniversary edition of Labelexpo Europe closed on a high note, its organizers report, saying it was the largest, most international show held to date. A total of 693 exhibitors participated at the event, which took place September 24-27, 2019 at the Brussels Expo in Belgium.

Spread over nine halls and covering almost 40,000 square meters of floorspace, up from 37,600 square meters in 2017, the show presented the largest offering of label and package printing technologies and live demonstrations ever seen at a Labelexpo. This included the fast growing areas of hybrid printing, flexible packaging and automation. Poor weather didn’t deter 37,903 visitors from 140 countries flocking to the four-day show – a substantial increase on 125 in 2017. India, China and Japan were especially well represented with large visitor delegations. Eastern Europe also showed a stronger representation compared to 2017, in particular Croatia, with a 51% increase, Lithuania (36%), Romania (25%), and Russia (14%). Brazil also saw a 14% increase in visitors compared to 2017.

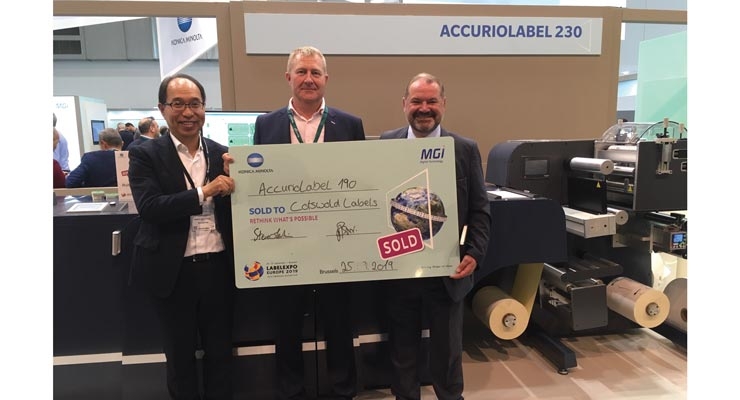

Major press manufacturers announced multiple sales on a daily basis, including: HP’s 200th HP Indigo 20000 digital press, sold to a Slovenian converter; Domino’s 7-color N610i inkjet press sold to a Belgian converter on day one; Lombardi’s sale of five Synchroline 430 presses during the first two days of the show; Gallus’ sale of three presses into India; Konica Minolta’s AccurioLabel 230 toner label press, sold on day one and which also debuted at the show; Grafisk Maskinfabrik’s DC350 digital converting line and a SR350 inspection slitter rewinder sold to a UK converter; Grafotronic’s laser diecutting system was sold to an American label converter after launching the machine at the show; and Screen’s first Trupress sold into Germany.

Indian machine manufacturers did particularly well, with UV Graphic Technologies selling seven Ultraflex UFO presses, Multitec selling its full servo S1 press to a Russian converter, and Monotech Systems selling three Colornovo presses, one each in China, Europe and Asia.

Chinese manufacturers also fared well, with sales highlights including label press manufacturer Wanjie’s sale of a printer to a converter in Spain. Rhyguan sold three finishing systems on day one – one to an Italian converter and two to companies in Germany.

Demonstrating that the show has evolved from a labels show into a wider package printing show, flexible packaging innovations were highlighted on the show floor, with press launches including Omet’s new X7 flexo printing machine for labels and flexible packaging with 26" (670mm) web width. Lombardi unveiled its Invicta i2 line, designed for flexible packaging in the mid web sector, while Nilpeter launched its 17" wide FA-Line press, featuring cold foil, lamination and its new high-speed semi-rotary diecutting unit.

Hybrid machinery was another key trend much in evidence, with launches including Bobst, who unveiled its new Master DM5 hybrid label press, and MPS, who launched a new 17"/430mm edition of the hybrid EF Symjet press. Mark Andy unveiled a new entry- to mid-level digital hybrid press, which was demonstrated live at the show with advanced inline converting.

Other machinery launches included Gallus’ Digital Printbar digital embellishing unit, designed specifically for opaque white and using inkjet-based digital print technology. Konica Minolta premiered its recently launched AccurioLabel 230, a new version of its digital toner press, while Grafotronic showcased seven new models out of a total 11 machines presented at the show.

Lisa Milburn, managing director of Labelexpo Global Series, said,“We are delighted that our 40th anniversary edition of Labelexpo Europe has been our largest, most international to date, especially as it is now rapidly moving forwards into a show that encompasses not just labels but also package printing. This was clear from the incredible array of flexible packaging innovations and hybrid machinery on the showfloor, giving label converters ever more options to diversify their businesses.

“The feedback we have received from visitors and exhibitors alike has consistently highlighted the superior quality of the leads, inquiries and contacts made at the show, with an incredible number of deals sealed on the exhibition floor and 83% of space already booked onsite for Labelexpo Europe 2021. This demonstrates that the global label and package printing industry remains as vibrant as ever, and that this show – 40 years on – is still a vital platform at the forefront of the entire supply chain.”

The show’s popular main feature, the Flexible Packaging Arena, drew in large crowds at every one of its 11 live demonstrations. Visitors witnessed a Xeikon CX500 (digital) and a Bobst M6 (UV flexo) producing indirect food contact flexible packaging to the latest GMP standards. In addition, HP Indigo offered live demonstrations of digital pouch making, showcasing the HP Indigo 20000 digital press, Pack Ready Lamination, and the Karlville pouch-making machine making its show debut on its stand. Other HP innovations at the show included the HP Indigo 8000 digital press, which ran inline with the ABG Fast Track die, and the best-selling HP Indigo 6900 digital press, which visitors could see in action with an integrated Kurz DM-Jetliner finishing module.

Reflecting increasing interest from Asia, and with Labelexpo Asia 2019 on the horizon, Labelexpo Europe also hosted its very first China Day on day one. This saw representatives from more than 100 label printers and converters from China visiting the exhibition, including the vice president of trade association PEIAC, a key show partner to Labelexpo Asia.

The popular educational program – the show’s most extensive to date – drew in attendees eager to boost their industry knowledge. Three expert-led Label Academy hosted master classes covered the hot topics of Inks, Coatings and Varnishes; Digital Label and Package Printing; and Flexible Packaging, while a workshop covered Self-Adhesive Label Materials.

The Label Industry Global Awards took place on the evening of day one, with winners from Avery Dennison, Esko, GMG and GEW honored at the 1980s themed celebration, which also marked Labelexpo’s 40th anniversary.

On the show floor

A highlight on the Epson stand this year at Labelexpo was a visually stunning mural art installation created from labels printed by Epson’s SurePress and ColorWorks digital label printers. Duncan Ferguson, VP professional printing and robotics at Epson Europe, commented, “Inkjet technology has now reached a maturity where it can make significant positive changes to label printing, both on-demand and at traditional converters. New product highlights on the Epson stand this year included the global launch of four new ColorWorks on-demand digital label printers (the ColorWorks CW-C6000Ae, CW-C6000Pe, CWC6500Ae, and CW-C6500Pe). These on-demand label printers extend Epson’s existing range and meet the needs of customers across many sectors (food, chemical, beverage, horticulture, logistics etc.). The range includes auto-cutter models (Ae) and timesaving auto-peeler (Pe) functionality that automatically removes the label backing paper and can be integrated seamlessly into existing print-and-apply production lines.

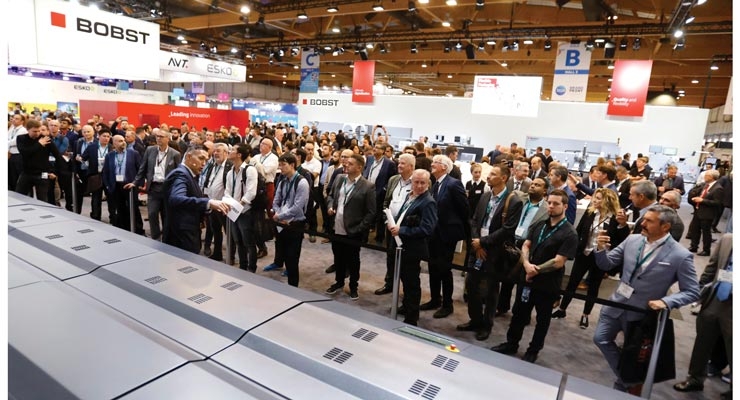

Bobst presented its largest label product portfolio featuring a new hybrid label press, flexo, and Mouvent digital printers. The portfolio on show included the world premiere of the Master DM5, a hybrid label press that provides the best possible combination of digital and DigiFlexo printing in a single press, and demonstrations of LB702-WB and LB701-UV, Mouvent’s advanced digital label printers. “Labelexpo 2019 is the perfect storm of recent innovation for Bobst and Mouvent,” said Federico D’Annunzio, Bobst program manager, hybrid printing. “As well as the world premiere of the Master DM5, we demonstrated a revolutionary DigiFlexo press and four complete digitalized production processes across a digital native press, equipped with water-based inks. These are innovations that address what matters most to converters and brand owners, namely improving time-to-market, guaranteeing color consistency and ensuring food packaging safety.”

Durst announced major expansions of its RSC platform of UV inkjet label presses. New dedicated label workflow and prepress software, together with an advanced modular Tau RSCi UV inkjet digital label press and low-migration inks, were shown for the first time at the event. Under the theme of “We Keep You Printing,” Durst announced a raft of product developments and world firsts as it continues to accelerate its presence in digital label inkjet printing. Dedicated workflow software for Web2Production and Durst’s own prepress software “Workflow Label” offered by Durst Professional Services to customize MIS integration software packages were showcased. New features of the Durst Workflow Label have been combined with the adapted Durst Smart Shop and integration packages to help fulfil Industry 4.0 standards and drive forward the expanded Tau RSC portfolio. New features for the RSC portfolio include a high opacity White Print Mode for an increased screen-like opacity and a High Speed White mode that allows high speed printing at 80 linear m/m of all colors, including white.

With new applications, new partnerships and the new advisory tool “Transform,” Xeikon created a buzz at Labelexpo Europe. Showcasing its largest booth yet at this show, the company displayed four different automated production lines. Across the show, Xeikon also participated in the Sustainability Insight Café and the Flexible Packaging Arena. Filip Weymans, vice president of marketing, stated, “At this year’s Labelexpo, Xeikon is announcing new partnerships, new innovations and new online tools. Our new advisory tool, ‘Transform,’ is already taking our customer service offerings to a different level. Digital label printing has become a mainstream technology with many suppliers, and the wealth of choice now available does not make it easy for label converters to choose what is best for their business. This is why Xeikon has created Transform to provide guidance to converters looking to move to digital for the first time or to optimize their existing digital operations. In the development of our new product lines, applications and sophisticated software, Xeikon has anticipated the worldwide consumer demand for experiential products in multiple sectors.

The Screen Truepress Jet L350UV SAI made its international debut in Brussels. The press features improved color reproduction, as well as excellent scalability, enabling it to meet a wide variety of market needs. Screen plans to launch the system worldwide in January 2020. Production levels for the global label printing industry continue to expand every year. There is particularly strong interest in labels and seals used in short-run limited and regional campaigns and those with unique designs to stimulate consumers’ desire to purchase. Screen developed the Truepress Jet L350UV in 2013, its first label printer designed specifically for this field. Since the initial release, wide ranging, continuous improvements have seen the L350UV series ship a total of more than 150 presses to date. Adoption has also been accelerating in Europe, where short runs are particularly beneficial for language localization, as well as the Americas and Asia.

Martin Automatic introduced Airnertia roller technology to label converters. Originally developed for transporting wide web, low basis weight materials, Airnertia rollers utilize an ultra-thin carbon fiber shell riding on a cushion of air. Ideal for low tension and high-speed processes, this low-inertia roller technology has found application in narrow web converting, specifically in intermittent motion processes that require the web to stop and start quickly. Visitors to the Martin stand were able to compare the touch and feel of an Airnertia roller with a similarly sized traditonal roller.Visitors also saw them in action on the nearby RotoControl stand, where managing director Marco Aengenvoort was reporting a 60% increase in process speed with the two Airnertia rollers fitted to the company’s DT340 Hybrid finishing line. Aside from Airnertia, Martin reported a strong opening to the Brussels show, with visitors impressed with running demonstrations of the MBSF (“F” for film) automatic unwind butt splicer and LRD non-stop automatic transfer rewinder. The splicer on show was specially designed for a limited-headroom production environment.

Fujifilm exhibited the benefits of its Illumina LED retrofit system. Fujifilm’s new, patented LED UV curing system was displayed in combination with the company’s new high performance LED UV inks, which allow any traditional UV or water-based flexo press to be converted to LED UV curing to deliver far-reaching improvements to label production on a narrow web press. Benefits of the system include increases to productivity, quality improvements, greater application versatility, cost and material savings, and a reduced impact on the working environment, as well as the environment as a whole. Illumina takes advantage of the very latest, high power but low heat LED UV curing technologies, along with Fujifilm’s renowned ink expertise, to deliver a reliable curing system with none of the disadvantages of higher power and higher temperature, UV lamps.

Elkem Silicones highlighted its Silcolease range for the pressure sensitive industry, including new members of its broad portfolio of release coatings. With the industry focused on productivity improvement and cost reduction, Elkem’s latest offerings are designed to show commitment to reducing energy consumption. Elkem Silicones introduced a new generation of engineered solvent-free polymers with the Poly 600 series, which fits seamlessly into its Optima solventless thermal range. This new range meets a vast array of needs, offering a further step-change in platinum content reduction while enabling faster converting speeds with ultra-flat release profile. Nicolas Capron, global business manager for the Silcolease range, said, “The use of the new Poly 600 series allows our customers to achieve up to 30% additional platinum reduction versus standard polymers. Customers at the show were very excited to learn about these new developments.”

Ritrama presented its latest adhesive technologies, which have been developed with sustainability and innovation in mind. The company placed the spotlight on “Core Linerless Solutions,” the technology platform developed in collaboration with Omet, Spilker and Ilti, which is capable of transforming the liner from waste into a resource while combining sustainability and cost reduction. The new technology is designed to eliminate the problem of liner disposal and reduce reel changes thanks to a greater number of labels per roll. Ritrama alsos showed the Ri-move range of self-adhesive labeling materials, developed to meet both recycling and reuse requirements for glass and PET containers and customer needs. The special adhesive technology ensures maximum adhesion during the product’s life-cycle while allowing fast and clean removal of the label from the container during industrial washing.

Domino exhibited its K600i digital UV inkjet printer at Labelexpo Europe. The 445mm wide dual bar, high-speed printer was integrated with an ABG Omega SRI (slitter, rewinder and inspection unit), printing 100% verified, high resolution, machine readable codes onto diecut labels. Printing up to 150 m/m at 600 x 600 dpi, including fine detail, Domino claims the K600i is capable of doubling production speeds while reducing the hourly cost of operation and improving profitability for label converters. The dual bar version is based on the same platform as the single bar K600i and the Domino N610i digital label press. During the show, Domino also demonstrated how variable data, such as text, sequential numbers, bar codes and 2D linear codes, including QR codes, can be printed at high speeds onto labels with 100% verification and minimal waste. Domino unveiled UV95, its new 7-color food packaging compliant UV digital ink set, as well. This product serves as a new ink option available for use with the N610i digital label press. “UV95 sets a new standard for UV digital inks and their use within non-direct food contact applications. I am delighted to have launched this new non-CMR ink set at Labelexpo,” said Louise Adcock, N-Series product manager. UV95 has been formulated for many non-direct food packaging applications and, under the right conditions, is migration compliant.

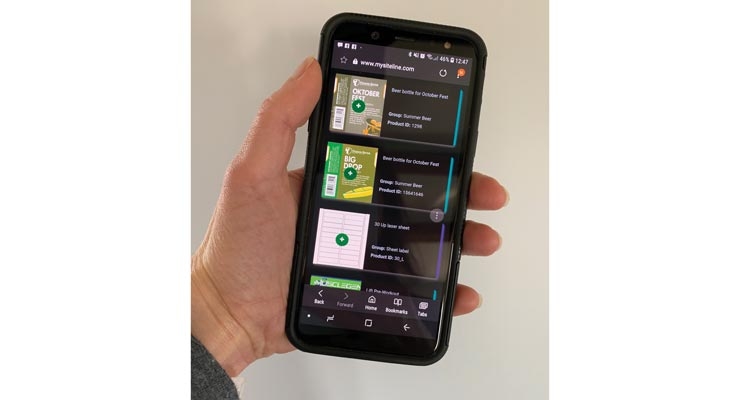

Label Traxx announced several new features to its products at the show. Label Traxx is an end-to-end management software system designed to improve converter efficiency and increase profitability. “As well as demonstrating the core functionality of our management software, we have a number of new capabilities we were pleased to introduce at Labelexpo,” said Label Traxx president Ken Meinhardt. “We were excited to demonstrate our new flexible packaging tools, proof approval procedures in our online customer portal Siteline and also the results of some optimization projects with key partners, including HP Indigo, Esko and Herma.” Label Traxx capabilities include dedicated flexible packaging workflows for companies selling unsupported film, sachets and pouches by weight. The tools available help with the accurate and consistent estimating of flexible packaging along with tailored features specifically for order processing.

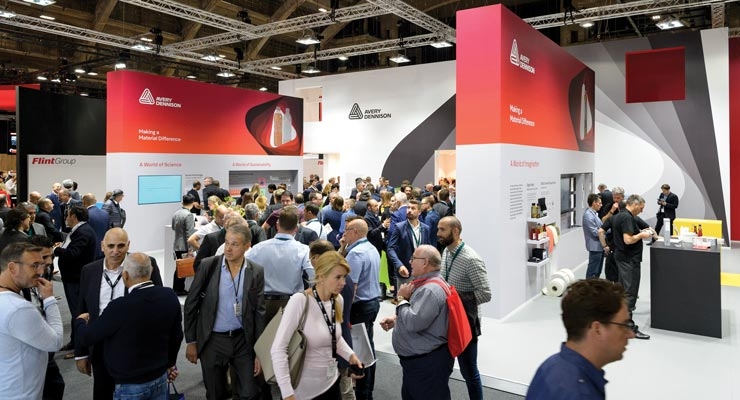

Avery Dennison introduced several new products to market, including its new Surfas Technology. This patent-pending adhesive technology increases surface contact for better initial tack to create a stronger hold on rough finishes like corrugated boxes. Surfas Technology, an ideal solution for e-commerce and logistics labeling needs, offers a sustainable edge and will be available at the same price as conventional labeling solutions for corrugated board. The newest in a long history of Avery Dennison adhesive technology developments, Surfas reduces the risk of curled or failed logistics labels to ensure on-time and accurate shipping. Corrugated cardboard can be a challenge for label adhesion, according to Eric Ide, senior product manager, Label and Packaging Materials Europe. Irregular surfaces require a more rigorous label adhesive that can bond to a wider variety of finishes. Surfas Technology is developed for ultimate strength and bond when labeling rough substrates. In addition to streamlining operations, increasing reliability and improving accuracy, the new adhesive coating technology offers sustainability advantages by using significantly less oil per square meter of material.

Vetaphone displayed four machines at Labelexpo Europe. For those looking for narrow web surface treatment, the company showed two corona stations. The VE1A-A (C4) features four ceramic electrodes and is designed for single-sided treatment, while the newly-launched VE1A-M (C8) has been designed for complex substrates and applications where high corona power is required from a single unit. Fitted with eight ceramic electrodes, the new C8 is capable of operating at running speeds in excess of 300 m/m. Both models are CE and UL approved, and like all Vetaphone corona units, they are developed for non-stop production and easy maintenance. Also new to the Vetaphone portfolio is a range of web cleaners that are designed to complement the company’s corona stations. Vetaphone highlighted a VE2A-W (double-sided) and VE1A-W (single-sided) unit, available in four widths from 350mm to 570mm and capable of running at 250 m/m. The intelligent design and use of high-quality elastomer cleaner rolls and perforated adhesive rolls ensure that all contamination is removed.

Tower Products unveiled its full line of pressroom products for flexographic and offset printers to Europe for the first time. According to Mark Principato, director of flexographic products, the company featured its SmartFlex line, a series of specialty chemicals tailored to fit any flexographic and packaging pressroom, and highlighted the LED/UV portion of the company’s product line. On the offset side, the Millennium Fountain Solution line of products was featured as solutions designed to help offset printers achieve new levels of quality with both conventional and UV inks. Both product lines are manufactured in Europe. Tower Products was officially joined in the booth by Tower Products Europe BV, a joint venture between Tower and Wifac BV of the Netherlands.

Mark Andy highlighted four product releases at Labelexpo Europe, including a new flexo press. Mark Andy introduced the Evolution Series to its suite of flexographic offerings. A simple-to-operate platform powered by proven Mark Andy engineering and technology, the Evolution Series provides converters a scalable production solution designed to serve modern business needs while providing adaptability to the needs driving future business growth. The Evolution Series, demonstrated live at the show, is available in 13" and 17" (330 and 460 mm) web widths with production speeds up to 750 fpm (230 m/m) and is available for immediate order. Tom Schelmbauer, chief business officer, Mark Andy Flexo, says the Evolution Series is a strategic addition to the company’s flexo solutions by providing full servo technology previously unattainable to this wide of a market range. “Full servo flexographic printing is now within reach for all converters,” explained Schelmbauer. “This technology, with the highest possible quality and engineering, has been a longstanding – and noticeably absent – request in the industry. Building on the success of our existing technology, we’re able to bring the Evolution Series to market as a solution for converters that need a label or film press, with the capability to grow as their business grows.”

AstroNova showcased the TrojanLabel T2-L, which, according to the company, is the world’s first narrow web digital flexible packaging press. Customers were able to see and test the new T2-L for the first time at Labelexpo Europe. Designed to accommodate both short-run and high-volume digital printing, the T2-L can provide flexible packaging products for brand owners, manufacturers, and commercial printers to efficiently scale and grow their businesses. Using Natura inks, which are formulated with nearly 70% water, the T2-L delivers excellent print quality onto flexible packaging using inks that are safe for food labels. The product is designed to create savings for customers over the lifetime of the printer.

MPS launched its new E-Sleeve technology at the event. The technology was presented during live demonstrations on the EF Symjet hybrid press. Designed as an alternative to traditional sleeves that use compressible material, the new MPS E-Sleeve enables printers to generate predictable results at increased speeds, with guaranteed quality tolerances and more reliable production cost calculations. “Flexographic printing sleeves play a critical role in the overall flexo printing process, as they have a major influence on print efficiency and quality,” says Bert van den Brink, MPS co-founder. “We at MPS saw the need to change from sleeves that use an aero-mounting principle with a compressible inner core, to a design with precise concentricity across the entire plate for optimum print results. It’s a game-changer for the printing industry.” Key features of the MPS E-Sleeve include optimum pressure settings to avoid unnecessary bouncing, precise concentric runout properties, constant parallelism for ideal register across the entire print length and increased dimensional accuracy for optimum register between all colors and die stations.

SPGPrints unveiled its new integrated RSI III rotary screen printing unit. The RSI III unit, which took center stage on SPGPrints’ stand, is a fast, cost-effective way of applying functional and tactile effects in one pass, at speeds of up to 150 m/m. Examples of its capabilities include a “no-label” look based on the printing of screen white at high opacity levels, creative varnishes, Braille, metallic foil and opaque, rich colors for striking brand design. The unit offers several safety and ergonomic features for increased productivity and time savings, as well. It also includes a new long-life web-cleaning scraper that automatically removes ink splashes from the web after stoppages or operation in slow rotation mode. This enables drying of the substrate while minimizing contamination of the rollers.

Actega Metal Print highlighted its EcoLeaf range. EcoLeaf can produce an assortment of colored metalized embellishments, with enhanced color richness. EcoLeaf metalization can help brands embellish labels, folding cartons, flexible packaging and more. Metallic embellishments are intended to beautify packaging and create a luxurious touch and feel on the shelf. To create colored embellishments, you colorize the conventionally printed trigger image before applying the metal pigments. Colorized EcoLeaf generates brilliant effects without adding material storage, overhead or waste. EcoLeaf has been designed as a sustainable alternative to creating decorative metallic embellishments on labels and folding cartons with conventional foiling. EcoLeaf uses only the amount of material required to create the metallic image, eliminating the need for foil and its associated waste.

During Labelexpo Europe, Sun Chemical exhibited its complete product portfolio for the narrow web label and packaging markets. Sun Chemical also demonstrated its commitment to sustainability, which continues to be fundamental to its product development. Sun Chemical used Labelexpo as a platform for the global launch of SolarVerse, a range of highly pigmented, low viscosity, multi-purpose UV flexo base concentrates, designed to be easily dispensed through a standard UV flexo dispenser and offering customers benefits in terms of cost savings and flexibility. By simply blending a SolarVerse base concentrate with a specific, optimized technology varnish, different, finished ink profiles can be produced, ready for use on press in whatever color is specified.

Matik and SEI Laser focused on their latest enhanced version of Labelmaster. On display were two models with web widths of 350 and 600 mm. With full digitalization, from order receipt to shipment, converters using the new Labelmaster can reach a new level of speed and productivity, the company says. Labelmaster, a complete and professional modular system for “roll to roll” and “roll to sheet” digital diecutting and finishing, is suitable for the production of self-adhesive labels in all sectors: industrial, wine, food and beverage, beauty, textiles, flexible packaging, promotional, converting and many others. During Labelexpo Europe, visitors had the opportunity to see the laser processing of different types of labels and special finishes on different materials – such as paper, PP and textile. The products have been developed by SEI Laser engineers from Curno (BG).

JM Heaford, a supplier of mounting and proofing solutions for the tag and label, flexible packaging, corrugated and gravure markets, built on its successful Labelexpo Americas 2018. Having sold all three mounters off the stand in Chicago, IL last September, the company saw similar interest for its scalable range of productivity boosters in Europe. Heaford’s showcase product on its stand was once again the company’s Label AutoMounter, which mounts any plate in less than one minute with an accuracy of five microns. The automated processes of the AutoMounter eliminates the need for skilled operators and makes it suitable for larger label producers running round-the-clock with multiple presses.

Valloy showed its Bizpress 13R, a 13" single-pass LED roll-to-roll label printer. The Bizpress 13R reaches a printing speed of 7.26 m/m and can handle 1,000 m2 jobs easily by changing rolls 3-4 times with up to 1200 × 2400 dpi. Bizpress 13R can print on 60 to 300 micron thick papers, PET, BOPP, PE and PVC films. An embedded high-voltage ionizer prevents static problems by enabling easy printing on metallic coated foils. It uses 18K high-capacity toner (26K for black) and a 100K high-capacity drum. In addition to its inherent low-temperature fusing system, an embedded cooling system and instant fusing mechanism helps a wider range of media compatibility. A pneumatic auto-tension control system drives 1km length rolls in a stable way while an intuitive touch panel GUI helps provide a comfortable operation. A web guide system is optionally available, too.

Kao Collins and Colordyne Technologies partnered with UPM Raflatac, a global manufacturer of pressure sensitive label materials, to bring high-quality digital inkjet labels to Labelexpo Europe. UPM is the primary material supplier for the digital inkjet label samples that were showcased in the Kao Collins booth. Colordyne and Kao Collins have been working with UPM Raflatac to identify a wide range of materials that are compatible with their new aqueous pigment inkjet technology, as well as to expand the media and application range for the UV inkjet print engine. At the event, attendees were able to visit the Kao Collins booth to receive a variety of label samples printed on UPM Raflatac material using Kao Collins’ ink and inkjet print engines manufactured by Colordyne. “Expanding the markets and applications we can serve is important for Colordyne and Kao Collins,” said Taylor Buckthorpe, director of sales at Colordyne Technologies. “One of our goals for collaborating with UPM Raflatac is to test and approve materials that deliver superior performance with our aqueous pigment and UV inkjet technologies. Identifying materials that perform well with our digital inkjet technologies allows us to better serve our customers and expand the applications they can produce.”

MGI and Konica Minolta joined forces at the show, displaying an integrated solutions portfolio highlighted by the JETvarnish 3D Web Color + digital print enhancement press. The JETvarnish 3D Web Color + is the world’s first inline label and flexible packaging solution for high-definition digital CMYK color printing, personalized 2D/3D dimensional textures and variable embossed foiling applications, the company stated. Labelexpo attendess also had the opportunity to see the AccurioLabel 230 digital color press, which is ideal for short and medium-range production runs. It succeeds the AccurioLabel 190 press, which fueled Konica Minolta’s rise in the global digital label marketplace. Also, the JETvarnish 3D Web Color + digital print enrichment press features semi-rotary cutting and slitting functionality – as well as both corona treatment and flexo primer coating stations for maximum substrate diversity and print surface flexibility.

QSPAC, a manufacturer of self-wound lamination products, discussed its latest solutions for labels and packaging at Labelexpo Europe. Based in Santa Fe Springs, CA, USA, the company offers BOPP and PET films coated with a high-performance and clear emulsion acrylic adhesive to provide an excellent finish and protection. “I really felt that this year’s Labelexpo Europe was the best turnout in the last five shows in which QSPAC has exhibited in Brussels,” said Howard Shen, director, Overlam Division, QSPAC. “The quality of interest was much higher, as we have put a lot of effort to grow our business outside of the North America market.” With a growing emphasis on digital printing, QSPAC displayed its lamination products for short-run digital. For digital printing, QSPAC has gloss and matte BOPP and PET films in 1.5 mil thickness.

Xitron launched Navigator Flexo Suite in Brussels. According to the company, the suite is generating attention among flexo shops interested in an economical alternative to expensive legacy products. “With so many new flexo CTP engines entering the market, many of which were on display in Brussels, Labelexpo was the perfect venue to begin introducing the package to end user prospects, as well as CTP manufacturers,” said Karen Crews, president of Xitron. “The first two days were extremely positive and demo appointments were beyond brisk.” Navigator Flexo Suite combines the Xitron RIP and Workflow with SmartFlexo screening and the new Navigator Plate Controller for final plate assembly. The four modules together represent a turnkey solution for economical flexo plate production, designed for use with any of the flexo CTP engines that accept one-bit TIFF input.

At Labelexpo Europe, Meech International presented its latest technological developments to support label production. The product range on display included CyClean R, Hyperion IonCharge 50-75w and IonCharge 30, and the Hyperion 960IPS. Meech also displayed its other well-established static control and web cleaning products. An enhanced version of Meech’s original CyClean, CyClean R is a single or double-sided non-contact web cleaner that utilizes positive and negative airflows to clean low-tension webs. It is ideal for wider webs where lower tensions are commonplace. It is compact and capable of handling high speed webs while using low levels of air consumption. Meech’s 924IPS bars have also been installed as a part of the system.

S-One Labels & Packaging announced a new partnership with Cellcoat Systems to bring the T14 Thermal Laminator to the narrow web labels and packaging market. The T14 Thermal Laminator, with its compact design, provides accurate tension control and high-speed capability, which are ideal for digital label and flexible packaging printing and converting, especially when speed to market and minimal material waste are critical. This move is intended for HP Indigo Series 3, HP6000 series and 330mm-wide press owners. The machine’s design includes an inline corona treater, lay-on roller, chill rollers, edge alignment and inline slitting that can all be managed by a single operator. The Cellcoat T14 Thermal Laminator is available in North America and EMEA exclusively through S-OneLP.

Under its 100-year anniversary banner, Nilpeter presented two of its FA-Line flagship presses. The FA-Line presses feature a number of new, enhanced technologies. The first FA-Line press on display was 17" wide, featuring cold foil and lamination, as well as Nilpeter’s new high-speed Semi-Rotary Diecutting unit. Introduced to the market for the first time, this press ran in combination with two new technologies: the High-Build Inkjet Varnish and High Opacity White Inkjet units. Nilpeter demonstrated the press’ versatility and value-adding capabilities within wine and beverage applications. The second press on the show floor was the all-new multi-substrate 22" FA-Line. It features a new 22" Quick-Change Die station, UV lamination and UV LED drying. With this press, Nilpeter showed attendees how to effectively print various food and beverage flexible packaging applications.

According to Gallus, Labelexpo Europe allowed the company to give label printers and converters more flexibility, which was showcased in the form of the conventional Gallus Labelmaster, with new and updated features. Two Gallus Labelmaster lines were running at the show: an 8-color Gallus Labelmaster and a 10-color Gallus Labelmaster Advanced, equipped with a new rotary quick-change diecutting unit, as well as the new Digital Printbar for printing white digitally with a high opacity. Live demonstrations featured the diecutting format change, as well as the process flexibility and its cost-efficiency.

Kocher+Beck’s GapMaster system was on display at the company’s Labelexpo Europe booth. The GapMaster was showcased alongside Kocher+Beck’s full portfolio of rotary diecutting technology and other products.

The rotary diecutting technology specialist’s GapMaster allows top and bottom-side stamping, and it can be used in different printing presses of the same type. It features a stable storage coupled with oil or air lubrication, and has been designed for dynamic applications and large material thicknesses. Kocher+Beck also highlighted its UR Precision non-stop product line, which guarantees an interruption-free supply of material in printing and finishing processes, the company says. This technology uses intelligent data networking functions, which were demonstrated during the exhibition.

Harper Corporation of America, a specialist in anilox roll technology, highlighted its expansive range of products. Visitors to the company’s booth had the opportunity to see the QD Proofer and QD Printer on display, with experts from Harper on-hand to explain all the latest technological benefits. According to Harper, the QD Proofing System is the first system that is fully portable and utility free, so it is not locked in the ink room. The QD Proofer can be carried straight to the press in order to dial in the proper amount of ink. Operators simply need to clip the substrate to the QD table and position the roller bearing guided carriage at the start position. The product is intended to draw down consistent proofs without variations in operator loading pressure.

Flint Group Narrow Web demonstrated the latest advances to Vivo Color Solutions, showcasing the newest inks and coatings for food packaging applications. The company also unveiled recent developments in the UV LED cured portfolio, including Dual-Cure technology. Examples of flexible packaging constructions, as well as prints made from Flint Group’s full portfolio of UV curable inks, were also on display. Vivo Color Solutions became commercially available to Flint Group Narrow Web customers in early 2019. Since then, the web-based system, which is designed to increase the converter’s color accuracy and reduce press downtime and substrate waste, has been expanded to include 180,000 ink formulations and Pantone references. Additionally, Vivo Color Solutions is now designed to feed formulations directly to ink dispensing equipment. These exciting advancements help converters meet color matching demands from designers and brand owners.

K Laser showed itsTruseamless holographic and fresnel lens films in metalized and transparent effect. Attendees were able to see these effects incorporated into the company’s booth design. During the show, K Laser also displayed numerous brand new label designs in PET, OPP, and cold foil labels, along with a series of new marketing materials. K Laser specializes in holographic and metalized print substrates. In the Americas, the company recently launched KoldFoil One, which allows converters to use the same roll of cold foil for flexo, offset or digital printing. This provides a greater color and holographic pattern selection, less inventory and faster product availability.

Flexo Wash featured a wide range of cleaning technologies from its comprehensive portfolio. Among the highlights were well-known products and the company’s new generation of cleaning systems. “Flexo Wash has always prided itself on its innovative and modern cleaning systems,” said Flexo Wash’s Henning Kongstad. “Now the focus that will lead us into the 2020s is directed towards easier handling, increased sustainability and improved technology. Our primary goal is to reduce our environmental footprint and create the best automatic cleaning solutions for the printing industry.” The new products at the booth include a next-generation anilox cleaner. The .NXT generation reduces waste, uses less power and uses environmentally friendly cleaning solutions. Plus, the Laser anilox cleaner is waste free and requires no water or drain.

GEW launched its newest product at Labelexpo Europe, the LeoLED UV curing system. LeoLED represents the next generation for LED UV curing and is set to have an impact in this highly competitive market. The technology has been redesigned and refined for simplicity and offers excellent value, while at the same time delivering maximum power and dose of UV energy. The LeoLED cassette is fully compatible with GEW’s ArcLED hybrid system and brings LED UV within affordable reach for all. The design of LeoLED brings several new benefits: the 50mm width window gives a long dwell time and is waterproof-sealed for easy cleaning. It is also resilient to dust and ink ingress. The LED array delivers electrical power at 88W/cm and an intensity of 25W/cm2, with minimal light loss due to the direct UV path. Furthermore, the integral water-cooling system gives LeoLED the ultimate operating capability and reliability in its class.

Mouvent provded live demonstrations of two of its digital label printers. On display were the industrialized LB702-WB, a high net output digital label printer using 100% water-based inks, and LB701-UV, a small, high flexibility, high productivity digital label printer. Attendees had the opportunity to bring and test their own jobs on the LB701-UV. In addition, a new launch by Bobst was a hybrid label press called Master DM5, which is driven by Mouvent digital inkjet technology. “Attendees at Labelexpo had the opportunity to see the full potential of digital label printing for themselves,” said Thierry Martin, CEO of Mouvent. “The LB702-WB is a really remarkable advance in digital label production as it uses only water-based inks, while the LB701-UV is extremely compact and ergonomic and enables highly flexible label production. These machines are the future of digital label printing.”

Wink showcased its full range of premium diecutting products at this year’s event. In addition to various SuperCut flexible dies and rotary cylinders, the main highlight at the Wink stand was the enhanced line of SmartGap adjustable anvils. The SmartGap adjustable anvil allows users to adapt the cutting depth precisely to different liner thicknesses. Even with demanding applications and thin liners, it is possible to achieve optimum diecutting results, as Wink has further optimized and extended the SmartGap system and showed all versions in live demos at the show. The new SmartGap Advance has been developed as the basic version of the system. Thanks to high-precision technology, the smallest adjustment steps are possible while maintaining the stability of the SmartGap system even at high speeds. The Advance can easily be upgraded to the digital SmartGap Touch, which was a finalist at this year’s Label Awards. Thanks to intuitive operation, maximum precision and many smart features, the “Touch” ensures excellent diecutting efficiency.

UPM Raflatac exhibited its wide range of sustainable labeling solutions. UPM Raflatac’s products are designed to help printers and brand owners reach beyond their sustainability goals by offering solutions to reduce, recycle and renew. The company’s thinner and lighter film materials reduce the use of raw materials. The UPM Raflatac PP Lite range combines a lighter face material, a lower coat-weight adhesive and a lighter backing, which makes them lightweight and optimizes the use of raw materials and resources. Ultrathin UPM Raflatac Vanish PCR labels are another good example, featuring 90% recycled content face and liners.

MPS Systems and Colordyne Technologies established a strategic partnership to bring new hybrid printing solutions to the market. The first developments of this partnership were unveiled at Labelexpo Europe. Both companies see an opportunity to work together on hybrid printing solutions that combine UV LED or water-based flexo technology with digital aqueous pigment inkjet technology. The new developments incorporate Colordyne’s digital print engine using Memjet’s DuraLink printhead technology integrated in the MPS EXL-Packaging product line. With the modular design of the EXL-Packaging product line, any combination of flexo and inkjet technology, plus additional machine functionalities and technologies, can be configured to meet the needs of the individual customer.

RotoMetrics highlighted many new and existing products and services at its two Labelexpo Europe booths. RotoMetrics displayed a variety of new rotary tooling solutions in its main booth, as well as digital solutions in its other booth, showcasing how to improve press performance. According to RotoMetrics, converters can now do more than ever with this technology. RotoMetrics launched new flexible diecutting technology, which broadly integrates Electro Optic diecutting technology into RotoMetrics’ processes. The result is enhanced die levelness, improved consistency and increased longevity for optimal performance on all materials, including the thinnest films and the most abrasive materials. “We have developed new solutions for IML, MDO, inline adhesive applications, liner variability and much more,” the company said in a statement. “RotoMetrics offers the best die with the fastest delivery time, with same-day shipping available.”

Graymills formally launched its Smarter Ink Pump family in Brussels. The Smarter Ink Pump family is the company’s newest development in peristaltic pumps. Smarter Pumps have a new physical appearance and smaller footprint than previous Graymills models and can be mounted vertically or horizontally and be easily adjusted in the field. They feature Graymills’ proven quick-disconnect removable head technology, which allows the pump head/tube changes to be accomplished in seconds without tools. Four distinguishing features of the new pumps were on display, indicating rotational speed; a predictive hose failure monitor; one button reverse drain shutdown sequence with an adjustable timer; and remote analog control with available digital connectivity.

AB Graphic International (ABG) and Cerm combined forces, debuting a new MIS/ERP integration in Belgium. During the past three years, ABG has rebuilt its complete machine software, and as a result, all computer-driven slitter rewinders that leave its factory now can receive instructions from the printer’s MIS/ERP system and can communicate back information for production and costing. “We believe that automation and robotization will continue to crawl into every printshop,” explained Matt Burton, ABG’s sales director. “We’ve invested heavily to be on the forefront of this trend by offering our customers a zero job setup time and by reducing the setup waste considerably on all our equipment.” ABG chose to partner in this development with Cerm, which has many years of experience with prepress and press information exchange, and was already interfacing to some of the existing ABG machines on a more basic level.

Siegwerk presented its broad range of UV, LED UV and solvent-based ink systems and special whites for all printing technologies suitable for sleeves used for non-food and food packaging applications. All inks and whites are always available as both standard and low migration ink systems.

BST eltromat International and Nyquist Systems showcased new options for web monitoring and 100% inspection with the systems in the TubeScan family. Nyquist Systems has been part of the BST Group since the beginning of 2019. Under the slogan “perfecting your performance,” BST eltromat and Nyquist exhibited the results of their collaboration with Hybrid Software at two exhibition booths. Hybrid Software is a global provider of products for PDF-based prepress-stage workflows and linkups to management information systems (MIS). The collaboration has enabled the two companies to simplify and speed up setup processes in label printing (including quality assurance). Visitors in Brussels also saw the latest options for the QLink workflow, which integrates quality assurance into the prepress stage, printing and assembly. More detailed technical options and features for the TubeScan product range were shown at the Nyquist booth. Alongside 100% inspection, the BST eltromat booth saw the presentation of the company’s entire range for quality assurance in narrow web processes—from web guiding, web monitoring and register control to color measurement, color management and workflow solutions.

Maxcesss presented its newest product lines at the show. The four-day event featured the latest product offerings from Fife, Tidland, Magpowr, Webex and Componex. On Display at Labelexpo from Maxcess: Fife - a new line of digital sensors that incorporate LED readouts for web position, LED light sources and data from the sensor itself in a digital output format. VEO-700 next-generation inspection system featuring LED strobe lighting for longer life, a graphical user interface and programmable positioning. Tidland - Control Series Electronic Knifeholder, an all-electronic knifeholder with a 360-degree blade guard to minimize operator interference and maximize the safety of the customer’s slitting operation. Magpowr - DLCA-NET, a tension amplifier with networking capabilities, offers the ability to transmit calibrated tension values over communications such as EtherNet/IP, PROFINET, Modbus TCP and EtherCAT CSR and ISR tension sensing idler rolls, and thin load cells were on display, as well. Componex - WINertia Dead Shaft Idlers maintain constant traction on high-speed webs and include built-in “air vents” that remove trapped air 7.5 times faster than any other idler roller on the market, according to Maxcess.

Cartes exhibited a wide range of products at Labelexpo Europe. Cartes showcased machines from the Series GT360 and Gemini in different versions, including the company’s advanced Laser converting system. The GT360 and Gemini series are recognized in the label market as a benchmark for making converting, finishing and complete high-quality embellished labels, the company said. Both platforms were developed with the latest technology in mind, designed to answer market needs. According to Cartes, it always highlights top performances in terms of precision and productivity for short- and medium-run jobs.

AVT presented integrated solutions for enhanced productivity and efficiency. Co-located with sister company Esko, AVT highlighted its newest, most advanced automated inspection solutions for label and packaging applications supported by next-generation workflow automation solutions per Industry 4.0 “smart factory” production. AVT’s products enable converters to set cross-plant quality standards in tandem with Esko’s Automation Engine (AE) and X-Rite’s ColorCert. AVT’s AutoSet module automates job setup by streamlining prepress to pressroom connectivity from the Esko Automation Engine to AVT’s inspection system. Meanwhile, the iCenter platform empowers printers to tightly control cross-site quality standards, ensuring global consistency.

INX International Ink Co. displayed a full range of conventional and digital products, including sustainable and dispensing solutions. INX has also unveiled a new food packaging product. “Considering the European market conditions and customer expectations, we were very excited to be a part of this year’s Labelexpo Europe,” commented Stefano Rogora, marketing manager EMEA for INX Digital. “As part of a global company, we are able to support our customers for the many different demands this market requires. That’s important because today’s world changes much faster. Customers know our products are safe and reliable, and when it comes to innovation, we have the solutions to keep them ahead of their competition.”

Recognizing the expanding role digital printing is playing in the label and package printing markets, Memjet and its OEM partners highlighted the latest developments in inkjet production. At the event, Memjet showcased the features of its third-generation printing technology called DuraFlex. In addition, Memjet OEM partners demonstrated an expanded range of Memjet-powered printing solutions that enable the fast, easy production of high-quality labels and packaging. “The market opportunity for inkjet label and package printers has never been stronger,” said Kim Beswick, general manager of Memjet’s benchtop and minipress division. “Localized food and beverage trends, combined with e-commerce business models, demand for mass versioning, and customization of marketing content means there is no end to the growth in demand for digital color labels and packaging. To capitalize on this key labeling and packaging trend – and tap into this growing market – OEMs are researching how to either make the move to inkjet or to expand the number or capabilities of their current line of inkjet printers.”

MPS and Domino together launched a wider version of their successful hybrid MPS EF Symjet press at Labelexpo Europe. Coming in a width of 17"/430mm, the new Domino N617i unit is fully integrated in the established MPS EFA flexo platform. The new press combination was displayed for the first time at the event. Louise Adcock, global commercial product manager at Domino Digital Printing Solutions, said, “The Domino N617i is based on our proven N6-series inkjet product range but has been designed exclusively for MPS. We are delighted that MPS was showcasing this solution at Labelexpo. The first N617i based MPS EF Symjet deliveries are being scheduled for January 2020.”

HP and Karlville introduced a complete solution for HP Indigo flexible packaging production. According to both companies, the new launch is set to break the production paradigm with a one-day pouch production process optimized for HP Indigo digital press printing. In the first live demonstration at Labelexpo of the HP Indigo Digital Pouch Factory concept, HP Indigo and Karlville showcased stand-up and three-side-seal pouch-making, using HP Indigo printing, Pack Ready laminating and slitting, and Karlville pouch-making. Compared to traditional methods, HP based production can be accomplished in a single shift, rather than weeks, enabling converters to profitably produce short run jobs.

Delta ModTech featured a Crusader Converter with its intuitive MOD-Track Vision Inspection System. Over 30 years ago, Delta designed the Crusader Converter from the ground up to be the most flexible and precise diecutting machine on the market, the company said. This rotary converter continues to be a successful option for the narrow web diecutting platform. Delta’s MOD-Track Vision system allows setup and real-time results to be viewed and adjusted on the machines’ touchscreen operator interface, without an engineer plugging into the system. The demonstrations at the show featured rotary diecutting with closed loop re-registration, vision inspection and multi-layer lamination. Also at the company’s booth, Frontier, a Delta ModTech Company, showcased slot-die coating on its DynaCoat. This turnkey coating and drying system has a small footprint and is suitable for lab scale, pilot scale or production coating. The demonstration included slot die coating to a precise thickness.

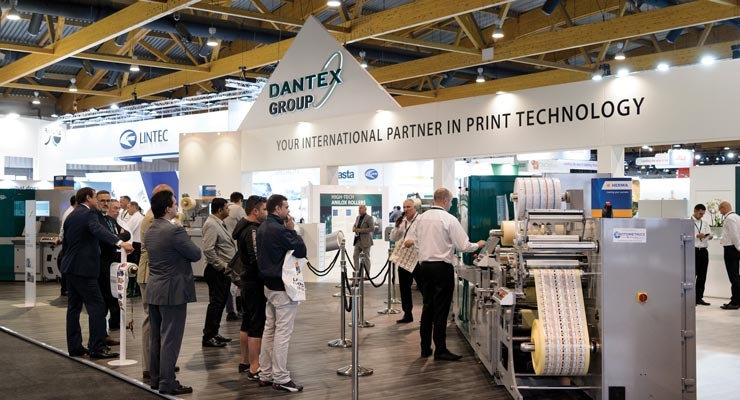

Dantex debuted its newest version of the PicoJet range, built by its Advance Engineering Team at Kettering. The PicoJet 350RF modular digital platform was highlighted, complete with inline finishing, together with its sister models, PicoJet 350R and PicoJet 254R. These two were showcased as reel-to-reel production versions, suitable for off-line finishing. All PicoJet models offer enhanced print quality and are capable of printing up to seven colors (CMYK + white + two are available with a range of user-friendly software and hardware options). To meet today’s digital requirements, Dantex Pico UV inkjet systems have been designed with speed, quality, versatility and cost of ownership in mind. The versatile PicoColour 210RF label press with inline finishing was also running on stand. Designed to meet every requirement with no minimum quantity, no waste and a fast turnaround, Dantex Pico digital solutions provide fast, easy and cost-effective label production, suitable for short and long run jobs.

At Labelexpo Europe, MacDermid Graphics Solutions introduced its Lava NW-M thermal processing unit to the European market, and the company also debuted its expanded Lux ITP inherently flat-top dot plates to include Lux ITP 60, Lux ITP M, and its newest plate – Lux ITP Epic. All three plates are formulated with the company’s patented Clean Plate technology, which reduces the number of press stops and ensures a cleaner print and better ink laydown. The Lux ITP plates, processed using the Lava thermal processing system, create a streamlined workflow for printers and converters to reduce platemaking time.

Kurz introduced a new stamping foil series for rotary label printing. The company also demonstrated the effective combination of digital web-fed printing and integrated metalization. The KPW XU cold foil grade, a versatile go-to for narrow-web printing, was displayed for the first time at Labelexpo Europe. According to Kurz, this cold foil solution is ideally suited for overprinting and delivers optimal decoration results, both for large-area and fine designs. A further development is the availability of Lumafin, a semi-transparent stamping foil specifically for web-fed printing. It allows under-printed designs to shine through, covers them with a shimmering gloss, and creates an extraordinary depth effect. A variety of labels decorated with Lumafin and the combination of color printing and Lumafin decoration were on display at the show.

Baldwin Vision Systems introduced its latest real-time monitoring and defect elimination solutions to the European market. With Guardian RTM Real-Time Monitoring, printers can track and compare many different production metrics. Press managers can monitor changes as they happen and make highly-informed decisions about print quality, defect management, and even operator-to-operator performance. The software addition to Guardian PQV 100% Print Inspection uses a central server to monitor, collect, and display real-time inspection data on a simple, uncluttered dashboard. RTM can simultaneously collect data for multiple presses, jobs and even across multiple plants. This enables printer customers to quickly identify any mechanical issues or process inefficiencies, and eliminate defects.

Omet demonstrated three machines on its two stands at Labelexpo Europe. The company launched the Omet X7, which is the latest addition to the XFlex line. On display live at the show, this machine is a flexo printing machine for labels and flexible packaging with a 26" (670mm) web width, which the company said is able to carry out the most complex jobs in a simple way. Omet also showcased its XJet powered by Durst, the hybrid flexo/inkjet machine. According to Omet, it is “the first and only machine currently on the market able to produce shrink labels with combined printing.” The third machine on display was the small iFlex, offering an 8-color flexo UV LED configuration. This product allows considerable energy savings and perfect drying at high speeds, Omet said.

Phoseon Technology introduced the FireJet FJ645 UV LED self-contained, air-cooled curing lamp for flexographic applications at Labelexpo Europe. With a 40mm wide emitting window, the FJ645 provides longer UV exposure time and greater dose, improving through-cure and adhesion of difficult to cure materials, especially with overprint varnishes, and dense blacks. The increased dose allows for higher speeds without the need for additional requirements such as exhaust blowers or water chillers. The FJ645 is designed for press manufacturers and converters looking for excellent performance and digital control. It is ideal for applications that require more dose and dwell time for better surface, depth cure and adhesion. The FJ645 is available in print widths up to 525mm and includes advanced digital interface capabilities for tight process control such as low migration processes for food packaging.

Dow introduced a range of new SYL-OFF silicone release coatings and Invisu acrylic adhesives designed for challenging paper and film label applications. With the new offerings, Dow has expanded its comprehensive portfolio for pressure sensitive label applications with products that address key market trends and enable manufacturers and converters to achieve material and energy savings while enhancing processing performance. “As a global leader in acrylic adhesives, silicone-based technologies and polyethylene resin, Dow is constantly searching to bring new solutions to the market that do more for our customers,” commented Meike Wesseling, global segment leader, Release Coating at Dow. “With this new range of silicone release coatings and high solids acrylic adhesives, we provide customers the opportunity to boost their competitiveness in the market by reducing costs and improving the footprint of the end products.”

PPG exhibited its PPG Teslin substrate for adhesive coaters, label converters and packaging specialists in Brussels. PPG Teslin substrate is a durable, secure and easy-to-print synthetic material that excels in applications that demand a tough, high-performance label solution. The substrate contains micropores that absorb inks, toners, adhesives and coatings, locking them into its structure for long-lasting durability and security with no additional processing or expense. This characteristic makes PPG Teslin substrate suitable for applications that require printed data to remain on labels such as brand protection, tamper-evident security, medical/pharmaceutical and in-mold applications. It is also used in the chemicals industry for labels that are compliant with the Globally Harmonized System (GHS) of Classification and Labeling of Chemicals and British Standard 5609 (BS 5609).

Konica Minolta announced the 450th global installation of its AccurioLabel presses. Providing excellent local service and support, along with delivery of parts and consumables, Konica Minolta’s digital toner-based technology has reached another label printing milestone after beginning successful trials less than four years ago. The 450th installation milestone was marked by live demonstrations of the AccurioLabel 230, the newest model in the toner label press family from Konica Minolta, which was a central feature on its stand. Important enhancements include a 73% speed increase, improved productivity, an option for overprinting, no warm-up required between jobs, less waste and more accurate print registration.

UEI Group presented the NW SpeedChase NXT system at the event. This new system is designed to change the way engraved hot stamping and embossing flat dies and counter forces are set up on a flat-bed narrow web press. The NW SpeedChase NXT system provides easier lock-up, quicker changeover, lower overall costs, increased speeds, and improved overall efficiency. It includes an NW SpeedChase NXT and a NW SpeedPlaten NXT, which use an NW UniLock-Up Plate Ejector NXT box to quickly set up and change jobs. Todd Rima, vice president of operations and sales, said, “Lock-up is now reduced to one steel plate for the engraved dies and one for the counter forces. Job changeover can be accomplished, on average, in as little as one minute.”

Paper Converting Machine Company (PCMC) displayed its Meridian laser anilox cleaner with live cleaning demonstrations. The Meridian removes deposited particles inside of the cells and extends the life of anilox rolls, as it does not require any chemicals, sodium bicarbonate, polymer beads, water or detergents – making it a sustainable cleaning technology with a very low environmental impact. PCMC’s newest Meridian models are designed for the narrow web market and include a new internal traversing vacuum system. “We were thrilled to welcome people into our stand to view the new innovations on our Meridian first-hand,” said Nicole Onesti, senior communications specialist at PCMC. “We know they are impressed by its technology, speed and effectiveness. This year marked a milestone for PCMC as we celebrated our 100-year anniversary, and we enjoyed sharing that excitement with visitors.”

Winners revealed at 16th Label Industry Global Awards

Avery Dennison, Esko, and GMG were among the category winners honored at this year’s prestigious Label Industry Global Awards, which took place on September 24 at Brussels Expo, Belgium, the first night of Labelexpo Europe 2019.

Now in its 16th edition, the awards recognize the most innovative, influential and successful work from the label and package printing industry across the globe in the last 12 months. The 1980s retro-themed ceremony brought together hundreds of guests featuring some of the biggest names from the international label community, and those working behind the scenes to constantly move this dynamic sector forward. It was the largest Label Industry Global Awards event yet as it also celebrated the 40th anniversary of Labelexpo.

The Award for Innovation (for companies with up to 300 employees), sponsored by Flint Group Narrow Web, was presented to GMG GmbH & Co. KG, for its GMG Calibration Creation Wizard. Developed to enable customers to create color-accurate mock-ups for labels, flexible packaging and cartons, the judges were impressed with how the company had connected GMG Color Management software with an Epson SC-S80600 to achieve such accurate reproducible proofs.

The Award for Innovation (for companies with more than 300 employees), sponsored by Xeikon, went to Esko for its Esko Print Control Wizard software, developed to simplify the implementation of screens and dot gain curves in the reprographics process. Its main feature is the ability to control where the transition from AM to FM occurs. The judges were impressed by the way that transition points can be changed at the touch of a button, enabling the operator to see the immediate impact on tonal values.

Avery Dennison won the Environmental & Sustainability Award for its Recycled PET Liners. The launch of the product in Europe has focused on meeting sustainability objectives and the need to support recycling in the packaging industry. The judges were impressed that the sustainable liners were made with 30% recycled PET post-consumer waste from PET bottles while maintaining the technical qualifications the liner material needs for supply chain labeling success.

The Rising Star Award went to Robert Rae of GEW. Rae joined the company in 2014 following an early career in research with P&G. With a top chemistry degree from Durham University, his skills have enabled him to make an immediate contribution toward developing a an enhanced LED product introduced in 2016, and now in launching a new LED system at Labelexpo Europe 2019. He has also been heavily involved with the UVFoodSafe Group.

The European Converter of the Year Award, sponsored by Grafisk Maskinfabrik, went to Reynders. Founded in 1956, Reynders has label plants and Centers of Excellence in Belgium, France, Poland, Spain and India. The judges felt that its recent developments in digitally-printed, full color booklets were especially noteworthy, since after only 18 months, the company’s investment in the production of “loyalty stamps” has resulted in over six billion labels printed and supplied to all corners of the world. Reynders also promotes sustainable label alternatives, with a planned installation of 800+ solar panels and investments to reduce water, gas and electricity consumption. Its emphasis on career growth and after work activities for employees also impressed judges.

A Special Recognition Award, sponsored by ILS, was also made to Clive Smith, founder of Labelexpo, honoring his creation and ongoing development of the largest label and package printing exhibition in the world and a leading event for 40 years. He entered the exhibition industry in 1968 and started his own company in 1974. In 1979, he launched the first labeling event in London, before the decision was taken in 1985 to move it to Brussels. Sister shows were launched in the USA in 1989, and in Singapore in 1991, creating a truly global brand. The company became the founding part of Tarsus Group in 1998, with Clive remaining as chairman of the Labels Division to this day.

The final award of the night, the R. Stanton Avery Global Achievement Award, sponsored by Avery Dennison, which was previously announced in June, went to Jim DeFife, VP pressure sensitive materials, Multi-Color Corporation. This award honors the contribution an influential individual has made, which has really impacted the growth of the international label industry. DeFife has been a driving force in the global label industry for almost 40 years, with a focus throughout his career on the development of technical solutions that have revolutionized and grown the pressure sensitive market – firstly with Avery Dennison and then, for the past 17 years, with Spear and Multi-Color.

The R. Stanton Avery Achievement Award is bestowed in memory of Stan Avery’s pioneering spirit and values. The award is a significant update to the previously named R. Stanton Avery Lifetime Achievement Award in order to better reflect the industry as it is today – one embracing innovation and tackling major environmental challenges such as label waste.

Mike Fairley, chair of the judges, said,“I, on behalf of the judging panel, would like to commend and congratulate all our finalists and winners at this year’s Label Awards. What really made them stand out was the demonstration of genuine brilliance in their innovation, leadership and sustainability, and dedication to improving their businesses. They illustrate the very best of the label and package printing industry, so it is important that their efforts are recognized in moving our industry ever forwards.

“These awards are also unique in that they are the only awards of their kind that celebrate both innovative companies across the globe and outstanding individuals in our industry. This year’s awards are particularly special as we also mark 40 years of Labelexpo with the addition of two new categories, so I sincerely hope all our winners will go on to inspire the next generation of innovators and leaders as we look ahead to the next 40 years of Labelexpo,” Fairley concluded.

As part of the Labelexpo 40th anniversary celebration, the retro 1980s theme for the evening featured Tony Hadley, singer and former member of chart-topping band Spandau Ballet, who performed to a delighted crowd and acted as host for the night. Guests also had the opportunity to try out a replica DeLorean and arcade games.

The Label Industry Global Awards were created in 2004 to celebrate innovation and excellence within the label and package printing sector. The Awards ceremony alternates each year between Labelexpo Europe (Brussels) and Labelexpo Americas (Chicago).

The members of the judging panel for this year’s awards were: Mike Fairley (chair), Steve Katz, editor, Label & Narrow Web, James Quirk, group managing editor, Labels & Labeling; Chris Ellison, president, FINAT; Craig Moreland, past chairman, TLMI; and Jean Poncet, editor-in-chief, MP Medias.

Spread over nine halls and covering almost 40,000 square meters of floorspace, up from 37,600 square meters in 2017, the show presented the largest offering of label and package printing technologies and live demonstrations ever seen at a Labelexpo. This included the fast growing areas of hybrid printing, flexible packaging and automation. Poor weather didn’t deter 37,903 visitors from 140 countries flocking to the four-day show – a substantial increase on 125 in 2017. India, China and Japan were especially well represented with large visitor delegations. Eastern Europe also showed a stronger representation compared to 2017, in particular Croatia, with a 51% increase, Lithuania (36%), Romania (25%), and Russia (14%). Brazil also saw a 14% increase in visitors compared to 2017.

Major press manufacturers announced multiple sales on a daily basis, including: HP’s 200th HP Indigo 20000 digital press, sold to a Slovenian converter; Domino’s 7-color N610i inkjet press sold to a Belgian converter on day one; Lombardi’s sale of five Synchroline 430 presses during the first two days of the show; Gallus’ sale of three presses into India; Konica Minolta’s AccurioLabel 230 toner label press, sold on day one and which also debuted at the show; Grafisk Maskinfabrik’s DC350 digital converting line and a SR350 inspection slitter rewinder sold to a UK converter; Grafotronic’s laser diecutting system was sold to an American label converter after launching the machine at the show; and Screen’s first Trupress sold into Germany.

Indian machine manufacturers did particularly well, with UV Graphic Technologies selling seven Ultraflex UFO presses, Multitec selling its full servo S1 press to a Russian converter, and Monotech Systems selling three Colornovo presses, one each in China, Europe and Asia.

Chinese manufacturers also fared well, with sales highlights including label press manufacturer Wanjie’s sale of a printer to a converter in Spain. Rhyguan sold three finishing systems on day one – one to an Italian converter and two to companies in Germany.

Demonstrating that the show has evolved from a labels show into a wider package printing show, flexible packaging innovations were highlighted on the show floor, with press launches including Omet’s new X7 flexo printing machine for labels and flexible packaging with 26" (670mm) web width. Lombardi unveiled its Invicta i2 line, designed for flexible packaging in the mid web sector, while Nilpeter launched its 17" wide FA-Line press, featuring cold foil, lamination and its new high-speed semi-rotary diecutting unit.

Hybrid machinery was another key trend much in evidence, with launches including Bobst, who unveiled its new Master DM5 hybrid label press, and MPS, who launched a new 17"/430mm edition of the hybrid EF Symjet press. Mark Andy unveiled a new entry- to mid-level digital hybrid press, which was demonstrated live at the show with advanced inline converting.

Other machinery launches included Gallus’ Digital Printbar digital embellishing unit, designed specifically for opaque white and using inkjet-based digital print technology. Konica Minolta premiered its recently launched AccurioLabel 230, a new version of its digital toner press, while Grafotronic showcased seven new models out of a total 11 machines presented at the show.

Lisa Milburn, managing director of Labelexpo Global Series, said,“We are delighted that our 40th anniversary edition of Labelexpo Europe has been our largest, most international to date, especially as it is now rapidly moving forwards into a show that encompasses not just labels but also package printing. This was clear from the incredible array of flexible packaging innovations and hybrid machinery on the showfloor, giving label converters ever more options to diversify their businesses.

“The feedback we have received from visitors and exhibitors alike has consistently highlighted the superior quality of the leads, inquiries and contacts made at the show, with an incredible number of deals sealed on the exhibition floor and 83% of space already booked onsite for Labelexpo Europe 2021. This demonstrates that the global label and package printing industry remains as vibrant as ever, and that this show – 40 years on – is still a vital platform at the forefront of the entire supply chain.”

The show’s popular main feature, the Flexible Packaging Arena, drew in large crowds at every one of its 11 live demonstrations. Visitors witnessed a Xeikon CX500 (digital) and a Bobst M6 (UV flexo) producing indirect food contact flexible packaging to the latest GMP standards. In addition, HP Indigo offered live demonstrations of digital pouch making, showcasing the HP Indigo 20000 digital press, Pack Ready Lamination, and the Karlville pouch-making machine making its show debut on its stand. Other HP innovations at the show included the HP Indigo 8000 digital press, which ran inline with the ABG Fast Track die, and the best-selling HP Indigo 6900 digital press, which visitors could see in action with an integrated Kurz DM-Jetliner finishing module.

Reflecting increasing interest from Asia, and with Labelexpo Asia 2019 on the horizon, Labelexpo Europe also hosted its very first China Day on day one. This saw representatives from more than 100 label printers and converters from China visiting the exhibition, including the vice president of trade association PEIAC, a key show partner to Labelexpo Asia.

The popular educational program – the show’s most extensive to date – drew in attendees eager to boost their industry knowledge. Three expert-led Label Academy hosted master classes covered the hot topics of Inks, Coatings and Varnishes; Digital Label and Package Printing; and Flexible Packaging, while a workshop covered Self-Adhesive Label Materials.

The Label Industry Global Awards took place on the evening of day one, with winners from Avery Dennison, Esko, GMG and GEW honored at the 1980s themed celebration, which also marked Labelexpo’s 40th anniversary.

On the show floor

A highlight on the Epson stand this year at Labelexpo was a visually stunning mural art installation created from labels printed by Epson’s SurePress and ColorWorks digital label printers. Duncan Ferguson, VP professional printing and robotics at Epson Europe, commented, “Inkjet technology has now reached a maturity where it can make significant positive changes to label printing, both on-demand and at traditional converters. New product highlights on the Epson stand this year included the global launch of four new ColorWorks on-demand digital label printers (the ColorWorks CW-C6000Ae, CW-C6000Pe, CWC6500Ae, and CW-C6500Pe). These on-demand label printers extend Epson’s existing range and meet the needs of customers across many sectors (food, chemical, beverage, horticulture, logistics etc.). The range includes auto-cutter models (Ae) and timesaving auto-peeler (Pe) functionality that automatically removes the label backing paper and can be integrated seamlessly into existing print-and-apply production lines.

Bobst presented its largest label product portfolio featuring a new hybrid label press, flexo, and Mouvent digital printers. The portfolio on show included the world premiere of the Master DM5, a hybrid label press that provides the best possible combination of digital and DigiFlexo printing in a single press, and demonstrations of LB702-WB and LB701-UV, Mouvent’s advanced digital label printers. “Labelexpo 2019 is the perfect storm of recent innovation for Bobst and Mouvent,” said Federico D’Annunzio, Bobst program manager, hybrid printing. “As well as the world premiere of the Master DM5, we demonstrated a revolutionary DigiFlexo press and four complete digitalized production processes across a digital native press, equipped with water-based inks. These are innovations that address what matters most to converters and brand owners, namely improving time-to-market, guaranteeing color consistency and ensuring food packaging safety.”