Greg Hrinya, Editor06.03.21

Label Solutions Inc.

3606 Asset St., Garland, TX, USA 75042

www.labelsolutionsinc.com

Chris Merlick has taken a different path than most to open up his label company, but the decisions he has made are paying off with flying colors. With an intimate knowledge of art and design, as well as a label printing pedigree, Merlick decided that he wanted to focus on premium labels and equip his company with the best technology. His vision has paid off, and today Label Solutions Inc. is seeing exponential growth and poised for a robust future.

Merlick received his indoctrination into label printing in the early 1990s, when he began working part-time at his father Carroll’s company, Label Corp. As a college student embarking on an art degree, Merlick got his start in Label Corp.’s art department, bringing the company’s prepress up to speed on a host of software platforms like Adobe Illustrator and Photoshop.

After college, Merlick moved to the GM position and helped the company triple in size. As general manager, he also helped overhaul the accounting department by transitioning all of the manual tasks to computers. Merlick’s father ultimately decided to sell his company, a move that came to fruition in 2008 when he agreed to a deal with WS Packaging. Merlick had helped prepare his father to sell, and he then needed to decide his own future. After careful deliberation, 12 months prior to the sale of Label Corp., Merlick chose to go his own way.

While it was a difficult decision to branch out on his own, Merlick, who hails from a family of entrepreneurs, opted to establish his own label converting company in March of 2007. Upon starting his new enterprise, Merlick purchased an 8-color Webtron 750 press.

“I got up and running, but the first year was pretty tough,” acknowledges Merlick. “Like a lot of people in their first year, you’re getting your feet wet and wearing a lot of hats. There was a lot of stuff I didn’t know, and I was essentially learning on the fly.”

Even though Merlick was learning the ropes, he had a vision for his business. He leaned on his art background and decided he wanted to produce premium labels for renowned brands. “I’ve seen how some businesses want to be everything to everybody, and I wanted to have a more focused approach,” explains Merlick. “I thought our direction should be centered on the higher margin, premium markets that not everybody can excel in. That’s really been our focus from day one. I’ve always wanted to push the envelope and the boundaries of what flexo can do. Flexographic plate, ink and anilox technology has come a long way since the 90s, and we have always strived to be at the forefront of that technology.”

Label Solutions has relied on partnerships and support from the local label community in establishing this thriving business, too. One such instance involved industry veteran Rex Hon, who had just sold his company, Prime Label.

“Rex showed up on my doorstep, and he was semi-unemployed at the time,” says Merlick. “If he hadn’t shown up, I probably wouldn’t have made it. He helped me from a mechanical standpoint, as he had run a label business since the 1970s. I also didn’t have an extensive background in accounting, so he helped me set up my books. From an operational standpoint, he was instrumental in our success. It was just me, one pressman – Albert Seturino – and Rex, and the three of us really got this operation off the ground.”

Relationships have been a cornerstone of Label Solutions’ success. Having been in the industry for now a number of years, Merlick has created strong ties with many local converters in the DFW area. In the company’s early years, Merlick relied on the “friendly” Dallas label community to establish connections. He has done extensive work with Abbott Label, Dac Label (now Western Shield), and Label Systems, all headquartered in the Dallas area.

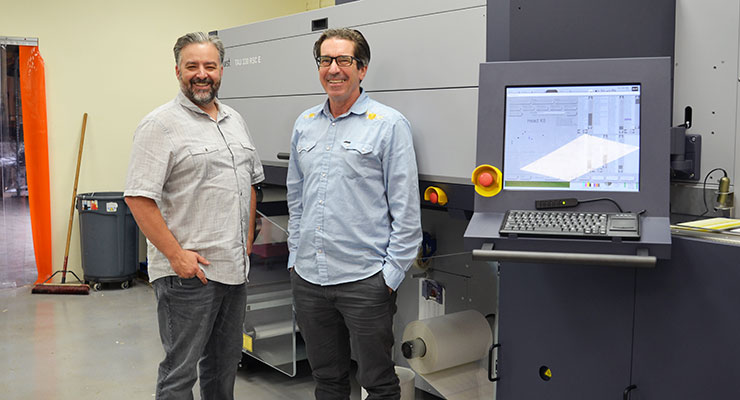

Merlick has assembled a strong team around him, as well. He has been opportunistic in identifying talent looking to make their next move, as he initially did with Hon and Seturino. In 2016, Merlick lured Justin Wright, who had parted with his previous company, to join the Label Solutions team. Although Wright initially joined to help Label Solutions integrate Label Traxx into its operations, his role has evolved considerably since. As Merlick’s right-hand man, Wright now operates as COO and CFO. Plus, he has earned an equity stake in the business.

“Justin’s skill set was pretty evident right at the start, and he was definitely a guy that we wanted on our team,” says Merlick. “After he joined, we lost our initial food customer that represented – at that time – about 25-30% of our business when they decided to sell. Justin brought on a good-sized customer and really helped guide us through a rough patch there. Thanks to him, we were able to keep our head above water and survive that situation. Since then, it’s just been steady growth every year. He’s earned his equity through diligence and the robust skill sets he brings to the table.”

“At the time, I focused a little more on the diecutting end of the business and non-prime labels, and Chris had a lot more prime label experience with the higher-end Nilpeter press,” recalls Wright. “It was just a really good fit.”

In addition to Wright, Seturino remains at the company, leading Label Solutions’ pressroom. Merlick also tabbed Ruth Lecroy to join the team. A materials guru, Lecroy has previous experience with Avery Dennison, UPM Raflatac and Technicote, and she excels in customer service.

“In the beginning, when it was just the three of us, I was doing sales, rewinding, bookkeeping, purchasing, invoicing – wearing a lot of hats,” Merlick acknowledges. “As we’ve grown, I’ve been able to take those hats and give them to other people, which has been great. And the people I have working with me now are great, and I have a lot of trust in them. I also have a lot of good people who have been with me a long time.”

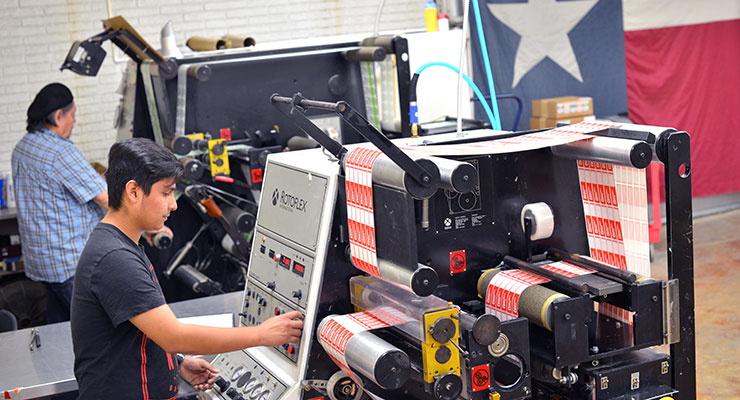

Today, Label Solutions has 14 full-time employees, as well as some part-time staff that comes in as the workload dictates. The company operates in an 8,000 square-foot facility, but management is actively looking to expand into a new space more suitable for its increasing workload and capabilities.

Label Solutions’ technological capabilities are quite extensive. In addition to partnerships with local converters and manufacturing businesses, Merlick has built strong ties with his equipment suppliers. Not long after securing his first big customer, Merlick invested in an 8-color Nilpeter FB330 full-servo press in 2010. This move allowed Label Solutions to significantly expand its premium label capabilities, including new opportunities in cold foil and expanded content, among others.

Label Solutions has also partnered with RotoMetrics, a Maxcess brand, and Wilson Manufacturing for tooling. In addition to its existing relationship with Label Traxx, Label Solutions decided to add Siteline this past year to keep up with its booming business and provide even better customer service.

Most recently, Label Solutions entered the digital printing arena by selecting the Durst RSC-E UV inkjet label press. The new press improves the company’s versatility, providing faster turnarounds and delivering a premium look for shorter runs. To improve its finishing capabilities, the company also added a Grafotronic DCL2.

“At the beginning of 2020, we were expecting 25% growth and ended up with about 75% growth,” notes Merlick. “We had some money to spend at the end of the year, so we bought some more modules for Label Traxx, we invested in the Durst press and the Grafotronic finisher. We also purchased Automation Engine from Esko to help automate our prepress workflow.

“In the interest of customer service, we’re creating an online ordering system through Siteline where our customers will be able to log in, see their order history and see the products we manufacture for them. They can then add those products to a cart and check out, just like Amazon or other online retailers. Our CSRs are using Siteline to write up orders too, and they’re finding it’s cutting the time to write up an order in half.”

Label Solutions delivers high-end labels in a wide range of markets. Although the company is strong in the food and beverage space, its diverse book of business was boosted by hand sanitizer and pet care products in 2020.

To ensure Label Solutions can continue to hit exacting brand colors, the company has worked with ACTEGA for its color management capabilities. “ACTEGA has provided us with some great software for color management,” comments Wright. “We’ve partnered with them on our flexo press to up our color management skills.”

Label Solutions also prides itself on creativity. In fact, its labels have often been seen on Major League Baseball fields and in PetSmart. PetSmart has lauded Merlick’s team for delivering what it says is, “the closest delta of anyone they’d ever measured” in terms of the company’s brand colors.

Meanwhile, Warstic, a baseball bat company, brought Label Solutions a project. They wanted to apply “Warstripe” decals to their bats. “Warstic came to us and wanted a decal with two stripes that were applied perfectly parallel each and every time,” says Merlick. “So we made some modifications to our Nilpeter press that allow us to apply a transfer tape after we diecut and strip the waste. After the tape is applied, we sheet the decal into individual pieces. What the customer gets is a decal that’s diecut with a transfer tape on the top. They remove the liner, then put the two stripes on the bat and then pull the transfer tape off, and the stripes are in the same place every time. It’s a cold foil project, and these bats have been used in MLB World Series games.”

Choosing the Ferrari

Even though Merlick has always relied on his expertise to push the boundaries of flexo, he increasingly saw the value in digital printing. As the company’s runs have gotten shorter and SKUs have proliferated, Merlick and Wright went to work on scouting out the latest and greatest digital presses on the market today.

Wright came to the company with some digital printing experience, which helped shape his vision for what he desired in a full production press. “I entered into the digital market with a Primera tabletop printer about eight or nine years ago, and I was really looking at getting into large scale industrial digital printing when I joined the team here,” says Wright. “It had been my focus to go in that direction for a long time, and Chris had that same vision.”

Label Solutions had been working with Abbott Label for smaller digital orders, but Merlick wanted to bring that business in-house – also optimizing the runs on its flexo machines.

“When we first started our digital journey and doing our due diligence, we looked at a number of manufacturers,” explains Merlick. “We sent files to all those partners, looked at samples and subsequently had quite a few meetings with them, and it really came down to Durst and one other manufacturer. Through our testing, Durst really rose to the top. We felt that with the 1200 dpi technology and 2 picoliter ink, we’re able to put down a real differentiator in terms of quality. Given that we’re selling ourselves as a premium provider of labels, that was a big part of it. The 1200 dpi technology and the number of Pantone colors we’re able to match with the expanded gamut ink really drove us to Durst.

“The Durst is a Ferrari in a sea of Chevrolets,” he adds. “As a premium label shop, there’s just something exotic about the Durst technology. It sets us apart from a lot of North American label converters, and we’re always looking for differentiators in this business. Not to say that there are not any other Durst presses out there, but we do have the only one in Texas and the Southwest.”

Financially, Durst made the most sense for Label Solutions, too. Through the evaluations of multiple manufacturers’ technologies, Wright put together a cost analysis to help crystallize their direction. “Looking at what the payments were going to be and the efficiency of the Durst, in terms of consumption, consumables and production capabilities, we both were right down the middle with our decision to go with Durst,” he says. “We both gravitated toward the technology, and the move made sense financially, as well.”

Merlick also views Durst as a strong partner and one that’s been supportive every step of the way. In the future, Label Solutions will be going to Durst for digital inks and an assortment of other press needs. “We see our vendors as partners, not just a one-off thing where we’re going to buy this press and that’s it. This is an ongoing relationship,” says Merlick. “The team at Durst has really emphasized that partnership to us.”

To that end, Label Solutions has volunteered its facility as a demo location for Durst. Despite only having the press installed for a few months, Label Solutions has already received a few visitors to look at the technology in-person.

Creating culture

Culture is not a buzzword at Label Solutions. In fact, Merlick and his team have gone to great lengths to instill and promote a positive company culture – and they have the analytics to prove it.

Merlick has utilized a company called Culture Index to evaluate his team’s strengths and weaknesses, all in an effort to optimize performance and put each team member in a position to succeed.

“The Culture Index is a tool we used to help us put the right people in the right seats. We ran our entire crew through the test and assessed the results,” explains Merlick. “When we looked at the findings, my strengths are Justin’s weaknesses, and Justin’s strengths are my weaknesses. We complement each other really well – and we did this for the whole team.”

This initiative was borne from Merlick’s experiences with Vistage, a peer networking group comprised of CEOs from various industries. “I was invited to Vistage by Ethan Mikes, a customer who had sold his very successful herb company and was looking to transition into a new role. I was in Vistage for about four years, and it was a great learning experience for me,” he says. “I didn’t really learn much about business from my fine art education, so that experience was really helpful to me, and that’s where I was exposed to the Culture Index.”

Label Solutions has adhered to these strategies and philosophies, which are evident in the company’s mission statement: “We strive for excellence in all we do to provide premium, customized label solutions for our customers and their brands.”

“To me, excellence means the way we answer the phone, what the box looks like when you’re shipping it to customers, how you present yourself, and how clean and organized your shop is – we’re striving for excellence in all we do,” explains Merlick. “It’s being the best at every little bit of our operation. I think that’s why our customers like us and why they want to continue doing business with us.”

The team at Label Solutions has responded, too. As an essential business, Label Solutions never ceased operating during the coronavirus pandemic. Merlick praises his team for rising to the occasion, especially working nights and weekends to ensure the orders were getting out on time. The company also relied on a part-time shift for help.

“We spent a lot more hours in the shop than we did in previous years, that’s for sure,” says Wright. “I felt like it was an all-hands-on-deck situation. A lot of the extra production came from within, where we had people working 50-60 hours a week. We implemented double-time on weekends and overtime after 8 pm, so we offered incentives to help push that extra work out the door. Financially, most everyone had the best year that they’ve ever had, and it was motivating for the team to keep going.”

“The team really went the extra mile and helped us get through a tough situation,” says Merlick. “It’s been a challenge for sure. I like to think my Vistage experience helped prepare me for that.”

Merlick also took advantage of his local ties to see Label Solutions through uncharted waters. As an active member of the Garland community, Merlick serves as a board member for the Garland Chamber of Commerce, and he’s also the president of the Dallas County Manufacturing Association.

“There’s a lot of manufacturing in the Garland area, so my connections there were very helpful in bouncing ideas off of other people,” he says. “Just like anything else, when life gives you lemons you make lemonade. The hand sanitizer business was great to have, and we ended up running over 10 million hand sanitizer labels over a three-month period. That was a challenge, but with good people and good vendors we were able to weather the storm.”

Continued growth

The future is certainly bright at Label Solutions. Coming on the heels of multiple equipment investments, the company is poised to move to a new manufacturing space.

“We are expecting to outgrow this facility in a year,” says Merlick. “In 2022, we plan to move because we are really jam-packed in here. We’re not able to bring any more equipment into this space, so we’re actively speaking with real estate agents and searching for a new building.”

According to Wright, Label Solutions will continue to invest, with a focus on the next generation of technologies. “We’re excited about growing,” he says. “While some people are taking their money home and putting it in the bank, we’re investing resources back into the company. We will continue to grow and invest in the technology that will make us the best in the industry.”

“Part of what we do is stay on top of the new technology and the latest trends in the label industry,” adds Merlick. “We want to be on the forefront of equipment, inks and coatings, substrates and laminates, and be current on what’s out there. Through our reading L&NW and going to Labelexpo every year, we stay on top of what the future holds. We also feel it’s important to stay informed on nationwide and global economic trends.

“One of our mantras is ‘begin with the end in mind,’ and that comes from Stephen Covey’s The 7 Habits of Highly Effective People,” he concludes. “We’re always refining our one-, three-, and five-year plans and constantly evaluating our path. One of the things Justin and I do is have a breakfast every Wednesday morning at 7 am, and that allows us to get outside the business and strategize. We are very excited about what the future has in store for Label Solutions Inc.”

3606 Asset St., Garland, TX, USA 75042

www.labelsolutionsinc.com

Chris Merlick has taken a different path than most to open up his label company, but the decisions he has made are paying off with flying colors. With an intimate knowledge of art and design, as well as a label printing pedigree, Merlick decided that he wanted to focus on premium labels and equip his company with the best technology. His vision has paid off, and today Label Solutions Inc. is seeing exponential growth and poised for a robust future.

Merlick received his indoctrination into label printing in the early 1990s, when he began working part-time at his father Carroll’s company, Label Corp. As a college student embarking on an art degree, Merlick got his start in Label Corp.’s art department, bringing the company’s prepress up to speed on a host of software platforms like Adobe Illustrator and Photoshop.

After college, Merlick moved to the GM position and helped the company triple in size. As general manager, he also helped overhaul the accounting department by transitioning all of the manual tasks to computers. Merlick’s father ultimately decided to sell his company, a move that came to fruition in 2008 when he agreed to a deal with WS Packaging. Merlick had helped prepare his father to sell, and he then needed to decide his own future. After careful deliberation, 12 months prior to the sale of Label Corp., Merlick chose to go his own way.

While it was a difficult decision to branch out on his own, Merlick, who hails from a family of entrepreneurs, opted to establish his own label converting company in March of 2007. Upon starting his new enterprise, Merlick purchased an 8-color Webtron 750 press.

“I got up and running, but the first year was pretty tough,” acknowledges Merlick. “Like a lot of people in their first year, you’re getting your feet wet and wearing a lot of hats. There was a lot of stuff I didn’t know, and I was essentially learning on the fly.”

Even though Merlick was learning the ropes, he had a vision for his business. He leaned on his art background and decided he wanted to produce premium labels for renowned brands. “I’ve seen how some businesses want to be everything to everybody, and I wanted to have a more focused approach,” explains Merlick. “I thought our direction should be centered on the higher margin, premium markets that not everybody can excel in. That’s really been our focus from day one. I’ve always wanted to push the envelope and the boundaries of what flexo can do. Flexographic plate, ink and anilox technology has come a long way since the 90s, and we have always strived to be at the forefront of that technology.”

Label Solutions has relied on partnerships and support from the local label community in establishing this thriving business, too. One such instance involved industry veteran Rex Hon, who had just sold his company, Prime Label.

“Rex showed up on my doorstep, and he was semi-unemployed at the time,” says Merlick. “If he hadn’t shown up, I probably wouldn’t have made it. He helped me from a mechanical standpoint, as he had run a label business since the 1970s. I also didn’t have an extensive background in accounting, so he helped me set up my books. From an operational standpoint, he was instrumental in our success. It was just me, one pressman – Albert Seturino – and Rex, and the three of us really got this operation off the ground.”

Relationships have been a cornerstone of Label Solutions’ success. Having been in the industry for now a number of years, Merlick has created strong ties with many local converters in the DFW area. In the company’s early years, Merlick relied on the “friendly” Dallas label community to establish connections. He has done extensive work with Abbott Label, Dac Label (now Western Shield), and Label Systems, all headquartered in the Dallas area.

Merlick has assembled a strong team around him, as well. He has been opportunistic in identifying talent looking to make their next move, as he initially did with Hon and Seturino. In 2016, Merlick lured Justin Wright, who had parted with his previous company, to join the Label Solutions team. Although Wright initially joined to help Label Solutions integrate Label Traxx into its operations, his role has evolved considerably since. As Merlick’s right-hand man, Wright now operates as COO and CFO. Plus, he has earned an equity stake in the business.

“Justin’s skill set was pretty evident right at the start, and he was definitely a guy that we wanted on our team,” says Merlick. “After he joined, we lost our initial food customer that represented – at that time – about 25-30% of our business when they decided to sell. Justin brought on a good-sized customer and really helped guide us through a rough patch there. Thanks to him, we were able to keep our head above water and survive that situation. Since then, it’s just been steady growth every year. He’s earned his equity through diligence and the robust skill sets he brings to the table.”

“At the time, I focused a little more on the diecutting end of the business and non-prime labels, and Chris had a lot more prime label experience with the higher-end Nilpeter press,” recalls Wright. “It was just a really good fit.”

In addition to Wright, Seturino remains at the company, leading Label Solutions’ pressroom. Merlick also tabbed Ruth Lecroy to join the team. A materials guru, Lecroy has previous experience with Avery Dennison, UPM Raflatac and Technicote, and she excels in customer service.

“In the beginning, when it was just the three of us, I was doing sales, rewinding, bookkeeping, purchasing, invoicing – wearing a lot of hats,” Merlick acknowledges. “As we’ve grown, I’ve been able to take those hats and give them to other people, which has been great. And the people I have working with me now are great, and I have a lot of trust in them. I also have a lot of good people who have been with me a long time.”

Today, Label Solutions has 14 full-time employees, as well as some part-time staff that comes in as the workload dictates. The company operates in an 8,000 square-foot facility, but management is actively looking to expand into a new space more suitable for its increasing workload and capabilities.

Label Solutions’ technological capabilities are quite extensive. In addition to partnerships with local converters and manufacturing businesses, Merlick has built strong ties with his equipment suppliers. Not long after securing his first big customer, Merlick invested in an 8-color Nilpeter FB330 full-servo press in 2010. This move allowed Label Solutions to significantly expand its premium label capabilities, including new opportunities in cold foil and expanded content, among others.

Label Solutions has also partnered with RotoMetrics, a Maxcess brand, and Wilson Manufacturing for tooling. In addition to its existing relationship with Label Traxx, Label Solutions decided to add Siteline this past year to keep up with its booming business and provide even better customer service.

Most recently, Label Solutions entered the digital printing arena by selecting the Durst RSC-E UV inkjet label press. The new press improves the company’s versatility, providing faster turnarounds and delivering a premium look for shorter runs. To improve its finishing capabilities, the company also added a Grafotronic DCL2.

“At the beginning of 2020, we were expecting 25% growth and ended up with about 75% growth,” notes Merlick. “We had some money to spend at the end of the year, so we bought some more modules for Label Traxx, we invested in the Durst press and the Grafotronic finisher. We also purchased Automation Engine from Esko to help automate our prepress workflow.

“In the interest of customer service, we’re creating an online ordering system through Siteline where our customers will be able to log in, see their order history and see the products we manufacture for them. They can then add those products to a cart and check out, just like Amazon or other online retailers. Our CSRs are using Siteline to write up orders too, and they’re finding it’s cutting the time to write up an order in half.”

Label Solutions delivers high-end labels in a wide range of markets. Although the company is strong in the food and beverage space, its diverse book of business was boosted by hand sanitizer and pet care products in 2020.

To ensure Label Solutions can continue to hit exacting brand colors, the company has worked with ACTEGA for its color management capabilities. “ACTEGA has provided us with some great software for color management,” comments Wright. “We’ve partnered with them on our flexo press to up our color management skills.”

Label Solutions also prides itself on creativity. In fact, its labels have often been seen on Major League Baseball fields and in PetSmart. PetSmart has lauded Merlick’s team for delivering what it says is, “the closest delta of anyone they’d ever measured” in terms of the company’s brand colors.

Meanwhile, Warstic, a baseball bat company, brought Label Solutions a project. They wanted to apply “Warstripe” decals to their bats. “Warstic came to us and wanted a decal with two stripes that were applied perfectly parallel each and every time,” says Merlick. “So we made some modifications to our Nilpeter press that allow us to apply a transfer tape after we diecut and strip the waste. After the tape is applied, we sheet the decal into individual pieces. What the customer gets is a decal that’s diecut with a transfer tape on the top. They remove the liner, then put the two stripes on the bat and then pull the transfer tape off, and the stripes are in the same place every time. It’s a cold foil project, and these bats have been used in MLB World Series games.”

Choosing the Ferrari

Even though Merlick has always relied on his expertise to push the boundaries of flexo, he increasingly saw the value in digital printing. As the company’s runs have gotten shorter and SKUs have proliferated, Merlick and Wright went to work on scouting out the latest and greatest digital presses on the market today.

Wright came to the company with some digital printing experience, which helped shape his vision for what he desired in a full production press. “I entered into the digital market with a Primera tabletop printer about eight or nine years ago, and I was really looking at getting into large scale industrial digital printing when I joined the team here,” says Wright. “It had been my focus to go in that direction for a long time, and Chris had that same vision.”

Label Solutions had been working with Abbott Label for smaller digital orders, but Merlick wanted to bring that business in-house – also optimizing the runs on its flexo machines.

“When we first started our digital journey and doing our due diligence, we looked at a number of manufacturers,” explains Merlick. “We sent files to all those partners, looked at samples and subsequently had quite a few meetings with them, and it really came down to Durst and one other manufacturer. Through our testing, Durst really rose to the top. We felt that with the 1200 dpi technology and 2 picoliter ink, we’re able to put down a real differentiator in terms of quality. Given that we’re selling ourselves as a premium provider of labels, that was a big part of it. The 1200 dpi technology and the number of Pantone colors we’re able to match with the expanded gamut ink really drove us to Durst.

“The Durst is a Ferrari in a sea of Chevrolets,” he adds. “As a premium label shop, there’s just something exotic about the Durst technology. It sets us apart from a lot of North American label converters, and we’re always looking for differentiators in this business. Not to say that there are not any other Durst presses out there, but we do have the only one in Texas and the Southwest.”

Financially, Durst made the most sense for Label Solutions, too. Through the evaluations of multiple manufacturers’ technologies, Wright put together a cost analysis to help crystallize their direction. “Looking at what the payments were going to be and the efficiency of the Durst, in terms of consumption, consumables and production capabilities, we both were right down the middle with our decision to go with Durst,” he says. “We both gravitated toward the technology, and the move made sense financially, as well.”

Merlick also views Durst as a strong partner and one that’s been supportive every step of the way. In the future, Label Solutions will be going to Durst for digital inks and an assortment of other press needs. “We see our vendors as partners, not just a one-off thing where we’re going to buy this press and that’s it. This is an ongoing relationship,” says Merlick. “The team at Durst has really emphasized that partnership to us.”

To that end, Label Solutions has volunteered its facility as a demo location for Durst. Despite only having the press installed for a few months, Label Solutions has already received a few visitors to look at the technology in-person.

Creating culture

Culture is not a buzzword at Label Solutions. In fact, Merlick and his team have gone to great lengths to instill and promote a positive company culture – and they have the analytics to prove it.

Merlick has utilized a company called Culture Index to evaluate his team’s strengths and weaknesses, all in an effort to optimize performance and put each team member in a position to succeed.

“The Culture Index is a tool we used to help us put the right people in the right seats. We ran our entire crew through the test and assessed the results,” explains Merlick. “When we looked at the findings, my strengths are Justin’s weaknesses, and Justin’s strengths are my weaknesses. We complement each other really well – and we did this for the whole team.”

This initiative was borne from Merlick’s experiences with Vistage, a peer networking group comprised of CEOs from various industries. “I was invited to Vistage by Ethan Mikes, a customer who had sold his very successful herb company and was looking to transition into a new role. I was in Vistage for about four years, and it was a great learning experience for me,” he says. “I didn’t really learn much about business from my fine art education, so that experience was really helpful to me, and that’s where I was exposed to the Culture Index.”

Label Solutions has adhered to these strategies and philosophies, which are evident in the company’s mission statement: “We strive for excellence in all we do to provide premium, customized label solutions for our customers and their brands.”

“To me, excellence means the way we answer the phone, what the box looks like when you’re shipping it to customers, how you present yourself, and how clean and organized your shop is – we’re striving for excellence in all we do,” explains Merlick. “It’s being the best at every little bit of our operation. I think that’s why our customers like us and why they want to continue doing business with us.”

The team at Label Solutions has responded, too. As an essential business, Label Solutions never ceased operating during the coronavirus pandemic. Merlick praises his team for rising to the occasion, especially working nights and weekends to ensure the orders were getting out on time. The company also relied on a part-time shift for help.

“We spent a lot more hours in the shop than we did in previous years, that’s for sure,” says Wright. “I felt like it was an all-hands-on-deck situation. A lot of the extra production came from within, where we had people working 50-60 hours a week. We implemented double-time on weekends and overtime after 8 pm, so we offered incentives to help push that extra work out the door. Financially, most everyone had the best year that they’ve ever had, and it was motivating for the team to keep going.”

“The team really went the extra mile and helped us get through a tough situation,” says Merlick. “It’s been a challenge for sure. I like to think my Vistage experience helped prepare me for that.”

Merlick also took advantage of his local ties to see Label Solutions through uncharted waters. As an active member of the Garland community, Merlick serves as a board member for the Garland Chamber of Commerce, and he’s also the president of the Dallas County Manufacturing Association.

“There’s a lot of manufacturing in the Garland area, so my connections there were very helpful in bouncing ideas off of other people,” he says. “Just like anything else, when life gives you lemons you make lemonade. The hand sanitizer business was great to have, and we ended up running over 10 million hand sanitizer labels over a three-month period. That was a challenge, but with good people and good vendors we were able to weather the storm.”

Continued growth

The future is certainly bright at Label Solutions. Coming on the heels of multiple equipment investments, the company is poised to move to a new manufacturing space.

“We are expecting to outgrow this facility in a year,” says Merlick. “In 2022, we plan to move because we are really jam-packed in here. We’re not able to bring any more equipment into this space, so we’re actively speaking with real estate agents and searching for a new building.”

According to Wright, Label Solutions will continue to invest, with a focus on the next generation of technologies. “We’re excited about growing,” he says. “While some people are taking their money home and putting it in the bank, we’re investing resources back into the company. We will continue to grow and invest in the technology that will make us the best in the industry.”

“Part of what we do is stay on top of the new technology and the latest trends in the label industry,” adds Merlick. “We want to be on the forefront of equipment, inks and coatings, substrates and laminates, and be current on what’s out there. Through our reading L&NW and going to Labelexpo every year, we stay on top of what the future holds. We also feel it’s important to stay informed on nationwide and global economic trends.

“One of our mantras is ‘begin with the end in mind,’ and that comes from Stephen Covey’s The 7 Habits of Highly Effective People,” he concludes. “We’re always refining our one-, three-, and five-year plans and constantly evaluating our path. One of the things Justin and I do is have a breakfast every Wednesday morning at 7 am, and that allows us to get outside the business and strategize. We are very excited about what the future has in store for Label Solutions Inc.”