Greg Hrinya, Associate Editor01.11.19

In a quarterly update, Xeikon explained its plans for the upcoming year, which comes on the heels of a banner 2018. With the help of Carlson Laboratories, Donna Covannon, director of marketing, Xeikon North America; Filip Weymans, vice president of global marketing; David Wilkins, vice president of sales for North America; and Danny Mertens, corporate communications manager for Xeikon recapped the previous year in a webinar while also looking ahead to several scheduled events.

“We had a good year in 2018,” said Wilkins. “We grew our business by 40% over the prior year, and we equaled what has been the record for number of sales in North America, and that was across the board in labels and packaging. So, we had an outstanding year and we’re looking forward to more growth in 2019.”

With the labels and packaging business growing “exponentially,” Xeikon will add account managers and sales staff to support market demand.

By unveiling Panther technology and acquiring Jetrion, Xeikon positioned itself to make a foray into UV inkjet printing. “For the first time after 30 years, we started to sell UV inkjet into the market, and that presented itself in the Panther portfolio,” explained Weymans. “That’s the outcome of a lot of R&D work that we’ve been doing for several years.”

“We came out very aggressively in that part of the labels space that we have not participated in before,” said Wilkins. “We’re migrating Jetrion customers over to Panther technology, which will be a continued opportunity in 2019, and converting customers with older equipment to new platforms.”

According to Wilkins, new sales were nearly split between existing and new customers. “We always have a number of presses we sell to existing customers, and that’s always the most satisfying to me because it shows that Xeikon provides business growth and allows them to expand their base with new technology,” he said. “This validates Xeikon’s promise of what the equipment does for them and the opportunities ahead.”

In 2018, Xeikon enjoyed several big releases, including the QB Toner and the Xeikon CX500. The new toner is designed to handle handling new legislation regarding food safety. Meanwhile, the CX500 was commercialized in the second half of the year. The press re-engineers the dry toner platform with new functionalities. In addition, Weymans added that Xeikon successfully launched its Label Discovery package at Labelexpo Americas.

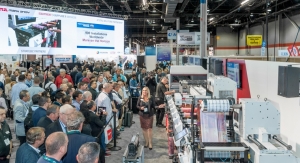

Major events will include Xeikon Café Europe, Xeikon Café North America, and several new Xeikon Café On Tour locations. Xeikon Café Europe will take place in Lier, Belgium (near Antwerp) from March 26-28, 2019, and the North American version will occur May 14-16 in Itasca, IL (near Chicago). The On Tour events will include a late-January stop in Milan, Italy and a later spring event slated for a Xeikon customer in the UK.

“We have some exciting events coming up this year. Building on a Total Solutions Approach, Xeikon Café is on a yearly frequency, and this event is designed to be end-use application driven,” said Mertens. “The mantra of the event is “Learn. Connect. Discover,” and we’ll put on an elaborate conference around 40 different types of labels and packaging applications.”

Xeikon Café Europe regularly attracts 1,000 visitors, where keynote presentations and a brand owner track will be featured. Customers will also discuss how they’ve benefited from Xeikon technology, and an Academy program will focus on the technical and business side of printing.

During the webinar, Carlson Laboratories explained how it shifted from flexo to digital in order to more efficiently print a wide range of nutritional supplements. Based in Arlington Heights, IL, the company produces more than 700 SKUs representing 200 products worldwide.

“Flexo wasn’t flexible for our 700 SKUs,” said Jared Thorson, vice president of sales and marketing at Carlson Laboratories.

“We looked at the order volumes we had to purchase for flexo, and we had a tremendous amount of waste,” said Thorson. “As we’re moving into many more countries, we also need language specifics so we can help all the different regions where we are.”

The Xeikon Duplex press has helped Carlson improve its ROI, and allowed the printing of a vast amount of in-house literature and marketing materials. The company also noted it was cost-efficient, food friendly, and FDA compliant.

By moving to digital printing, Carlson now produces an average of 556,000 labels and 135,000 pieces of literature and marketing materials each month. Carlson is able to batch multiple labels into one job and not rely on significant inventory. The monthy savings have translated into $45,000 in printing costs and eliminated waste of $90,000 in destroyed obsolete labels.

Xeikon will provide another update on its yearly progress in April 2019.

“We had a good year in 2018,” said Wilkins. “We grew our business by 40% over the prior year, and we equaled what has been the record for number of sales in North America, and that was across the board in labels and packaging. So, we had an outstanding year and we’re looking forward to more growth in 2019.”

With the labels and packaging business growing “exponentially,” Xeikon will add account managers and sales staff to support market demand.

By unveiling Panther technology and acquiring Jetrion, Xeikon positioned itself to make a foray into UV inkjet printing. “For the first time after 30 years, we started to sell UV inkjet into the market, and that presented itself in the Panther portfolio,” explained Weymans. “That’s the outcome of a lot of R&D work that we’ve been doing for several years.”

“We came out very aggressively in that part of the labels space that we have not participated in before,” said Wilkins. “We’re migrating Jetrion customers over to Panther technology, which will be a continued opportunity in 2019, and converting customers with older equipment to new platforms.”

According to Wilkins, new sales were nearly split between existing and new customers. “We always have a number of presses we sell to existing customers, and that’s always the most satisfying to me because it shows that Xeikon provides business growth and allows them to expand their base with new technology,” he said. “This validates Xeikon’s promise of what the equipment does for them and the opportunities ahead.”

In 2018, Xeikon enjoyed several big releases, including the QB Toner and the Xeikon CX500. The new toner is designed to handle handling new legislation regarding food safety. Meanwhile, the CX500 was commercialized in the second half of the year. The press re-engineers the dry toner platform with new functionalities. In addition, Weymans added that Xeikon successfully launched its Label Discovery package at Labelexpo Americas.

Major events will include Xeikon Café Europe, Xeikon Café North America, and several new Xeikon Café On Tour locations. Xeikon Café Europe will take place in Lier, Belgium (near Antwerp) from March 26-28, 2019, and the North American version will occur May 14-16 in Itasca, IL (near Chicago). The On Tour events will include a late-January stop in Milan, Italy and a later spring event slated for a Xeikon customer in the UK.

“We have some exciting events coming up this year. Building on a Total Solutions Approach, Xeikon Café is on a yearly frequency, and this event is designed to be end-use application driven,” said Mertens. “The mantra of the event is “Learn. Connect. Discover,” and we’ll put on an elaborate conference around 40 different types of labels and packaging applications.”

Xeikon Café Europe regularly attracts 1,000 visitors, where keynote presentations and a brand owner track will be featured. Customers will also discuss how they’ve benefited from Xeikon technology, and an Academy program will focus on the technical and business side of printing.

During the webinar, Carlson Laboratories explained how it shifted from flexo to digital in order to more efficiently print a wide range of nutritional supplements. Based in Arlington Heights, IL, the company produces more than 700 SKUs representing 200 products worldwide.

“Flexo wasn’t flexible for our 700 SKUs,” said Jared Thorson, vice president of sales and marketing at Carlson Laboratories.

“We looked at the order volumes we had to purchase for flexo, and we had a tremendous amount of waste,” said Thorson. “As we’re moving into many more countries, we also need language specifics so we can help all the different regions where we are.”

The Xeikon Duplex press has helped Carlson improve its ROI, and allowed the printing of a vast amount of in-house literature and marketing materials. The company also noted it was cost-efficient, food friendly, and FDA compliant.

By moving to digital printing, Carlson now produces an average of 556,000 labels and 135,000 pieces of literature and marketing materials each month. Carlson is able to batch multiple labels into one job and not rely on significant inventory. The monthy savings have translated into $45,000 in printing costs and eliminated waste of $90,000 in destroyed obsolete labels.

Xeikon will provide another update on its yearly progress in April 2019.