12.03.19

The power of color is well known and brand owners use color to engage with customers in many ways. Indeed, research shows that up to 85 percent of customers’ first impression is based on color alone, and color increases brand recognition by up to 80 percent.

We all know the Nivea BLUE and the Coca-Cola RED. Color quality and consistency was and remains a very strategic and sensitive topic for both brand owners, printers and converters. As technology evolves, it is important to understand the perspective of brand owners and their view on the latest developments in color management.

Bobst recently spoke to brand owners at six leading global companies, encompassing food, beverages, tobacco and pharmaceuticals, about the challenges they face around the colors on their brand packaging, and how they consider more digitalized color solutions in their packaging production workflows. The responses heard reflect the high pace of change in this area, as The digitalization of color in packaging: a bright future?

The changes driven by the Extended Color Gamut (ECG) are significant. It is the biggest driver to simultaneously improve color consistency and production efficiency while reducing cost and environmental impacts.

The observations and recommendations you will find below are very important in a world where the digitalization and the automation of processes are driving forces.

“Color fidelity is now table stakes. Without demonstrable accuracy and precision, you are not a player," says Marc Hufschmied, Senior Manager R&D Packaging Innovation at PepsiCo, lays the situation out in plain terms.

Color consistency is a must-win battle for brand owners.

“Consumers are very color sensitive, and have expectations around brand colors that need to be met consistently in a global marketplace,” he continues. “Their trust in the product encompasses packaging graphics. Packaging is the ‘last sales force’. It is vital that we adhere strictly to consistency standards and quantifiable verification systems.”

Hufschmied says that consistency is the “number one challenge for Brand Owners around color." Achieving consistency has traditionally been challenging due to the sheer variety of printing processes, inks, and substrates involved.

Michele Amigoni, Group RDQ – Vice President, Global Packaging at the Barilla Group, agrees. “Like all global companies, we have had color consistency issues,” he says. “Take a Barilla pasta box in the US and compare it to one in Italy, and it might happen that you will not get exactly the same color consistency. We have standardized everything to have the same look, but still does not always happen consistently across converters, printing technologies and runs, and countries.”

But what are the consequences of inconsistency?

“The issue is brand perception,” says Amigoni. “In extreme situations it can also lead to readability issues, although that is rare.”

As well as diluting brand perception, issues with colors on packaging dilute brand differentiation from competitors, and for certain brands could make life easier for counterfeiters (if consumers are used to seeing color inconsistency, a counterfeit package would appear less suspicious).

There is also the matter of consistency between online imagery and real-life packaging. A recent report asked shoppers about their expectations around packaging. Forty-seven percent said they expect that the item they ordered online will look exactly the same when they see it in person. And although 37% say that it’s OK to have “minor variations” between the online image and the package they receive in the mail, only 9% are fine with a package that arrives with different colors or imagery.3

As one brand owner from a major global food company said, “Inconsistency puts doubts in the consumer’s mind.” If there is an issue with the packaging, he argues, then there are immediately concerns about the product inside. Also, there is the matter of trust and brand recognition. People see a certain color and they are acquainted with it.

The challenges around color consistency are exacerbated by current trends.

“There are several key trends in packaging that are affecting this area, but in particular there are two main ones,” says Alvise Cavallari, Packaging Transversal Technologies at Nestlé Research and Development. “The first is to bring packaging that is more sustainable while still ensuring the safety and quality of products. The second trend, which has been ongoing for many years, is the desire by Brand Owners and consumers alike to differentiate the product through the packaging.”

With the advent of big data, we know more about what consumers want than ever before, which leads to a desire to customize packaging that precisely targets audiences and markets. This inevitably means more variation, more SKUs, which requires greater flexibility, shorter runs and shorter turnaround times, putting more pressure on printers and converters. All the while, the need to maintain high quality – including color fidelity and consistency – remains.

“Runs are becoming shorter and are putting pressure on our supply chain stock level,” says Michele Amigoni from Barilla. “The segmentation of the market is leading to more complexity internally. We need to accelerate our time to market, and to do that we need to become more agile in all the steps of the chain, from artwork creation to approval to color separation, print and delivery.”

The way that color is used on packaging is also changing, and this has an impact on the printing presses.

In recent years, minimalist designs have been at the forte of packaging, with all the clutter stripped away, leaving a cleaner look and a clear brand message. This means that the colors that remain on the packaging are even more important. Gradients are also used more widely now, helping to provide an element of dimension and freshness to modern designs.

Greater digitalization and automation have been transformative across the packaging industry.

Stephen Jones, Manager Digital Integration (Packaging) at Philip Morris International, agrees that digitalization is the way to go at a time when speed of response is critically important.

“As we continue moving forward in our journey to provide better alternatives to adult smokers who would otherwise continue smoking cigarettes, the speed at which we bring our products into the marketplace becomes even more critical,” he says. “With the new products we are entering a world that is dynamic, fast and more unpredictable than ever – which variants will consumers buy most, which ones will have to be replenished soonest? In order to keep pace we need to change the ways we make our products: waiting two or three months to get our printed materials is no longer an option for us. The flexibility and speed that digital offers, plays a key role in helping us support the transformation we are going through."

“Greater digitalization can enable shorter production lead times, smaller runs, improvements in the way we manage color consistency, and also better efficiency,” agrees Agustí Mercè, Product Operations Planning Manager at global pharmaceutical company Almirall.

“We are using conventional, economy-of-scale machines for very agile jobs”

In an era of more numerous but shorter runs, flexibility is one of the biggest assets of more digitalized technology.

Companies are doing shorter runs, smaller batches, diversifying the packaging more, all resulting in many more SKUs. But as one Brand Owner puts it, “We are using conventional, economy-of-scale machines for more and more agile jobs.” More agile printing technologies that enable efficient printing with high color consistency are likely to increase in demand.

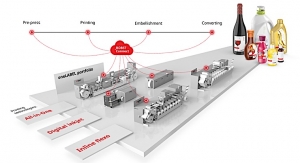

The digitalization and automation of the flexographic process (known as DigiFlexo) has provided an exciting middle ground, bridging the gap between what digital printing can do and what ‘traditional’ flexo technology delivers. The digitalization of the flexographic process has made it consistent and therefore easily repeatable, with very quick job changes and start-ups, and minimum waste.

From a color perspective, the DigiFlexo innovation has brought consistent color matching and control, an appealing benefit for Brand Owners.

“Digital and DigiFlexo options are appealing – we are looking into them to see if they can help us to achieve shorter operation times and deliver more color consistency,” says Michele Amigoni from the Barilla Group. “The process becomes more standardized, with less room for human error. As well as greater consistency, digitalized color solutions mean quicker time to market, better stock management, and good opportunities for data collection and analysis. We are certainly looking into DigiFlexo, mainly for labels at the moment.”

And it’s not just color consistency from job to job, but the reassurance of knowing throughout the process that the digital colors are accurate – “creating expectation and achievability,” as one Brand Owner puts it. Digitalizing colors and being able to simulate the consistency among substrates at the design stage, creates higher expectations and achievability at the printing stage. If it is possible to digitally communicate these colors to all parties in the graphic chain, then this helps to get the results in line with expectations. It also means that companies can digitally measure and control each of the productions according to a digitalized color standard.

One of the biggest drives to simultaneously improve color consistency and production efficiency has been the Extended Color Gamut, or ECG.

ECG printing uses three additional ink colors on top of the conventional colors of cyan, magenta, yellow, and black (CMYK), enabling a match with 95%+ of the Pantone book, compared with approximately 65% previously. This means there is no need to keep huge inventories of spot colors, but these can be added if required. And the digitalization of color matching has made 100% color conformity with the job master request possible. It ensures color matching of packaging worldwide, irrespective of the geographical location of the printing facilities or the different ability of the press operators.

“ECG provides a very good option to improve color matching without extending the stock of inks and produces probably better results than standard CMYK,” says Agustí Mercè from Almirall.

The use of ECG is on the rise. The Pantone company estimates that 15-25% of all packaging is printed using ECG (based on printers using ECG software), and this is expected to increase more than 50% within the next decade.

“I am convinced that moving away from spot colors – where you have thousands of inks on a shop floor – will have a big impact on reducing cleaning time and on sustainability,” says Alvise Cavallari from Nestlé. “Spot colors have been a good way to bring color consistency, but today we are convinced that with standard process colors it is possible to reach sufficiently good color consistency. In this way we can avoid spot colors, which are associated with high costs. I believe that in the future, ECG will become standard.”

ECG speeds up time to market and turnaround time.

“The key competitive advantage for us would be speed to market,” says one Brand Owner. “The quicker we can launch a new packaging the better, and there’s no question that the speed would improve with a fixed sets of inks. Also, we would know at the design stage which colors are achievable. We expect a certain quality standard, which spot colors bring today, but with the increasing need for more colors and speed to market, together with the future integration of digital printing, ECG is something to investigate further.”

In 2013, BOBST launched the REVO DigiFlexo project with a team of leading industry partners. REVO has succeeded in making available to converters a turnkey 7-color ECG printing process and digitalized workflow; a closed loop solution with fixed partners for consumables, hardware and software equipment and devices.

Converters using a REVO package can start with ECG from day one. Because REVO packages contain in-line color measurement and standardization of all print elements including plate, anilox, inks, pre-press, substrates and inspection, consistency can be achieved.

ECG is in fact the default way to produce colors in digital presses. The recently announced Mouvent technology has developed proprietary screening technologies for the optimization of the ECG process. A wide color gamut range is achievable using the unique Mouvent Cluster print-heads and the digital workflow and color matching are perfectly integrated for label production.

For post-print flexo in corrugated, BOBST also utilizes ECG technology in the THQ FlexoCloud presses. All spot colors are realized from the process colors and there is an integrated process with printing plates and inks from approved suppliers and a cloud application for coordinating its production.

With the continuing rise of ECG in the near future, flexo and digital inkjet are expected to share the same color space, so the same jobs can be printed with different technologies without differences in colors and quality perception. Digitalized closed-loop solutions will enable quality and color control to achieve digitalized print consistency worldwide, regardless of whether the technology is flexo or digital. Recent innovations have taken us a step closer to that reality.

Bobst has recently introduced two innovations relating to flexo inking and color matching: Ink-on-Demand (IoD) and DigiColor. The Ink-on-Demand inking system – which works for all substrates for labels, flexible packaging and folding carton applications – is a revolutionary concept in inking technology. It is a clean and smart system that operates with only 30 grams of ink in the print unit. It eliminates ink trays and chambered doctor blades. Full wash-out and ink changes are performed in minutes with only a few grams of ink and washing liquid wasted. It delivers consistent print quality at high speed, high productivity and a sustainable operation, ease of operation and high flexibility.

DigiColor, the solution for REVO ECG printing takes the IoD concept one step further: the hue of the ink dispensed to the print unit can be automatically digitally adjusted during printing.

For Agustí Mercè from Almirall, the peace of mind provided by DigiColor is very appealing. “For Brand Owners, it could mean being able to relax about color control, as the printing process is automatically controlled,” he said.

DigiColor represents the very first closed-loop color control system in the flexo industry, acording to Bobst. For the first time it is possible to transform the final printed product from DigiFlexo back to a digital file to be able to compare it with the original digital native file.

The printer extracts digital values from printed job, producing a “digital twin” of the original file. This means that for the first time, Brand Owners can review a digital twin and validate the colors from the original digital file – no more guessing – just facts. This effectively “closes the loop” starting with a digital file, utilizing digital automation to complete the job, and validating the output with another digital file.

Converters and brand-owners will now be able to rely on a new digital technology to protect their brand identities, and will benefit from major time savings and quality improvement benefits.

“A closed loop approach to color consistency is an extremely powerful concept and very interesting,” comments Alvise Cavallari from Nestlé. “If we can use process colors with a closed loop system, then we can ensure to achieve the stability and consistency that we need.”

“We want printing to go from an art to a science and to rely less on the influence of the operator,” agrees a Brand Owner from a global food company. “Having a digital file that we can calibrate and recreate anywhere in the world? This is the future. DigiColor could provide real competitive advantages. Now I want to see it proven for my brands.”

The future of color fidelity and consistency in product packaging – whether printed via flexo or digital inkjet – is bright. New innovations are ushering in the prospect of digitalized closed-loop systems and worldwide print consistency, with the speed and flexibility required in today’s high-pressure consumer environment.

For brand ownders, this brings reassurance their brand packaging will retain the full power and impact of the brand colors that they – and their consumers – are so invested in.

We all know the Nivea BLUE and the Coca-Cola RED. Color quality and consistency was and remains a very strategic and sensitive topic for both brand owners, printers and converters. As technology evolves, it is important to understand the perspective of brand owners and their view on the latest developments in color management.

Bobst recently spoke to brand owners at six leading global companies, encompassing food, beverages, tobacco and pharmaceuticals, about the challenges they face around the colors on their brand packaging, and how they consider more digitalized color solutions in their packaging production workflows. The responses heard reflect the high pace of change in this area, as The digitalization of color in packaging: a bright future?

The changes driven by the Extended Color Gamut (ECG) are significant. It is the biggest driver to simultaneously improve color consistency and production efficiency while reducing cost and environmental impacts.

The observations and recommendations you will find below are very important in a world where the digitalization and the automation of processes are driving forces.

“Color fidelity is now table stakes. Without demonstrable accuracy and precision, you are not a player," says Marc Hufschmied, Senior Manager R&D Packaging Innovation at PepsiCo, lays the situation out in plain terms.

Color consistency is a must-win battle for brand owners.

“Consumers are very color sensitive, and have expectations around brand colors that need to be met consistently in a global marketplace,” he continues. “Their trust in the product encompasses packaging graphics. Packaging is the ‘last sales force’. It is vital that we adhere strictly to consistency standards and quantifiable verification systems.”

Hufschmied says that consistency is the “number one challenge for Brand Owners around color." Achieving consistency has traditionally been challenging due to the sheer variety of printing processes, inks, and substrates involved.

Michele Amigoni, Group RDQ – Vice President, Global Packaging at the Barilla Group, agrees. “Like all global companies, we have had color consistency issues,” he says. “Take a Barilla pasta box in the US and compare it to one in Italy, and it might happen that you will not get exactly the same color consistency. We have standardized everything to have the same look, but still does not always happen consistently across converters, printing technologies and runs, and countries.”

But what are the consequences of inconsistency?

“The issue is brand perception,” says Amigoni. “In extreme situations it can also lead to readability issues, although that is rare.”

As well as diluting brand perception, issues with colors on packaging dilute brand differentiation from competitors, and for certain brands could make life easier for counterfeiters (if consumers are used to seeing color inconsistency, a counterfeit package would appear less suspicious).

There is also the matter of consistency between online imagery and real-life packaging. A recent report asked shoppers about their expectations around packaging. Forty-seven percent said they expect that the item they ordered online will look exactly the same when they see it in person. And although 37% say that it’s OK to have “minor variations” between the online image and the package they receive in the mail, only 9% are fine with a package that arrives with different colors or imagery.3

As one brand owner from a major global food company said, “Inconsistency puts doubts in the consumer’s mind.” If there is an issue with the packaging, he argues, then there are immediately concerns about the product inside. Also, there is the matter of trust and brand recognition. People see a certain color and they are acquainted with it.

The challenges around color consistency are exacerbated by current trends.

“There are several key trends in packaging that are affecting this area, but in particular there are two main ones,” says Alvise Cavallari, Packaging Transversal Technologies at Nestlé Research and Development. “The first is to bring packaging that is more sustainable while still ensuring the safety and quality of products. The second trend, which has been ongoing for many years, is the desire by Brand Owners and consumers alike to differentiate the product through the packaging.”

With the advent of big data, we know more about what consumers want than ever before, which leads to a desire to customize packaging that precisely targets audiences and markets. This inevitably means more variation, more SKUs, which requires greater flexibility, shorter runs and shorter turnaround times, putting more pressure on printers and converters. All the while, the need to maintain high quality – including color fidelity and consistency – remains.

“Runs are becoming shorter and are putting pressure on our supply chain stock level,” says Michele Amigoni from Barilla. “The segmentation of the market is leading to more complexity internally. We need to accelerate our time to market, and to do that we need to become more agile in all the steps of the chain, from artwork creation to approval to color separation, print and delivery.”

The way that color is used on packaging is also changing, and this has an impact on the printing presses.

In recent years, minimalist designs have been at the forte of packaging, with all the clutter stripped away, leaving a cleaner look and a clear brand message. This means that the colors that remain on the packaging are even more important. Gradients are also used more widely now, helping to provide an element of dimension and freshness to modern designs.

Greater digitalization and automation have been transformative across the packaging industry.

Stephen Jones, Manager Digital Integration (Packaging) at Philip Morris International, agrees that digitalization is the way to go at a time when speed of response is critically important.

“As we continue moving forward in our journey to provide better alternatives to adult smokers who would otherwise continue smoking cigarettes, the speed at which we bring our products into the marketplace becomes even more critical,” he says. “With the new products we are entering a world that is dynamic, fast and more unpredictable than ever – which variants will consumers buy most, which ones will have to be replenished soonest? In order to keep pace we need to change the ways we make our products: waiting two or three months to get our printed materials is no longer an option for us. The flexibility and speed that digital offers, plays a key role in helping us support the transformation we are going through."

“Greater digitalization can enable shorter production lead times, smaller runs, improvements in the way we manage color consistency, and also better efficiency,” agrees Agustí Mercè, Product Operations Planning Manager at global pharmaceutical company Almirall.

“We are using conventional, economy-of-scale machines for very agile jobs”

In an era of more numerous but shorter runs, flexibility is one of the biggest assets of more digitalized technology.

Companies are doing shorter runs, smaller batches, diversifying the packaging more, all resulting in many more SKUs. But as one Brand Owner puts it, “We are using conventional, economy-of-scale machines for more and more agile jobs.” More agile printing technologies that enable efficient printing with high color consistency are likely to increase in demand.

The digitalization and automation of the flexographic process (known as DigiFlexo) has provided an exciting middle ground, bridging the gap between what digital printing can do and what ‘traditional’ flexo technology delivers. The digitalization of the flexographic process has made it consistent and therefore easily repeatable, with very quick job changes and start-ups, and minimum waste.

From a color perspective, the DigiFlexo innovation has brought consistent color matching and control, an appealing benefit for Brand Owners.

“Digital and DigiFlexo options are appealing – we are looking into them to see if they can help us to achieve shorter operation times and deliver more color consistency,” says Michele Amigoni from the Barilla Group. “The process becomes more standardized, with less room for human error. As well as greater consistency, digitalized color solutions mean quicker time to market, better stock management, and good opportunities for data collection and analysis. We are certainly looking into DigiFlexo, mainly for labels at the moment.”

And it’s not just color consistency from job to job, but the reassurance of knowing throughout the process that the digital colors are accurate – “creating expectation and achievability,” as one Brand Owner puts it. Digitalizing colors and being able to simulate the consistency among substrates at the design stage, creates higher expectations and achievability at the printing stage. If it is possible to digitally communicate these colors to all parties in the graphic chain, then this helps to get the results in line with expectations. It also means that companies can digitally measure and control each of the productions according to a digitalized color standard.

One of the biggest drives to simultaneously improve color consistency and production efficiency has been the Extended Color Gamut, or ECG.

ECG printing uses three additional ink colors on top of the conventional colors of cyan, magenta, yellow, and black (CMYK), enabling a match with 95%+ of the Pantone book, compared with approximately 65% previously. This means there is no need to keep huge inventories of spot colors, but these can be added if required. And the digitalization of color matching has made 100% color conformity with the job master request possible. It ensures color matching of packaging worldwide, irrespective of the geographical location of the printing facilities or the different ability of the press operators.

“ECG provides a very good option to improve color matching without extending the stock of inks and produces probably better results than standard CMYK,” says Agustí Mercè from Almirall.

The use of ECG is on the rise. The Pantone company estimates that 15-25% of all packaging is printed using ECG (based on printers using ECG software), and this is expected to increase more than 50% within the next decade.

“I am convinced that moving away from spot colors – where you have thousands of inks on a shop floor – will have a big impact on reducing cleaning time and on sustainability,” says Alvise Cavallari from Nestlé. “Spot colors have been a good way to bring color consistency, but today we are convinced that with standard process colors it is possible to reach sufficiently good color consistency. In this way we can avoid spot colors, which are associated with high costs. I believe that in the future, ECG will become standard.”

ECG speeds up time to market and turnaround time.

“The key competitive advantage for us would be speed to market,” says one Brand Owner. “The quicker we can launch a new packaging the better, and there’s no question that the speed would improve with a fixed sets of inks. Also, we would know at the design stage which colors are achievable. We expect a certain quality standard, which spot colors bring today, but with the increasing need for more colors and speed to market, together with the future integration of digital printing, ECG is something to investigate further.”

In 2013, BOBST launched the REVO DigiFlexo project with a team of leading industry partners. REVO has succeeded in making available to converters a turnkey 7-color ECG printing process and digitalized workflow; a closed loop solution with fixed partners for consumables, hardware and software equipment and devices.

Converters using a REVO package can start with ECG from day one. Because REVO packages contain in-line color measurement and standardization of all print elements including plate, anilox, inks, pre-press, substrates and inspection, consistency can be achieved.

ECG is in fact the default way to produce colors in digital presses. The recently announced Mouvent technology has developed proprietary screening technologies for the optimization of the ECG process. A wide color gamut range is achievable using the unique Mouvent Cluster print-heads and the digital workflow and color matching are perfectly integrated for label production.

For post-print flexo in corrugated, BOBST also utilizes ECG technology in the THQ FlexoCloud presses. All spot colors are realized from the process colors and there is an integrated process with printing plates and inks from approved suppliers and a cloud application for coordinating its production.

With the continuing rise of ECG in the near future, flexo and digital inkjet are expected to share the same color space, so the same jobs can be printed with different technologies without differences in colors and quality perception. Digitalized closed-loop solutions will enable quality and color control to achieve digitalized print consistency worldwide, regardless of whether the technology is flexo or digital. Recent innovations have taken us a step closer to that reality.

Bobst has recently introduced two innovations relating to flexo inking and color matching: Ink-on-Demand (IoD) and DigiColor. The Ink-on-Demand inking system – which works for all substrates for labels, flexible packaging and folding carton applications – is a revolutionary concept in inking technology. It is a clean and smart system that operates with only 30 grams of ink in the print unit. It eliminates ink trays and chambered doctor blades. Full wash-out and ink changes are performed in minutes with only a few grams of ink and washing liquid wasted. It delivers consistent print quality at high speed, high productivity and a sustainable operation, ease of operation and high flexibility.

DigiColor, the solution for REVO ECG printing takes the IoD concept one step further: the hue of the ink dispensed to the print unit can be automatically digitally adjusted during printing.

For Agustí Mercè from Almirall, the peace of mind provided by DigiColor is very appealing. “For Brand Owners, it could mean being able to relax about color control, as the printing process is automatically controlled,” he said.

DigiColor represents the very first closed-loop color control system in the flexo industry, acording to Bobst. For the first time it is possible to transform the final printed product from DigiFlexo back to a digital file to be able to compare it with the original digital native file.

The printer extracts digital values from printed job, producing a “digital twin” of the original file. This means that for the first time, Brand Owners can review a digital twin and validate the colors from the original digital file – no more guessing – just facts. This effectively “closes the loop” starting with a digital file, utilizing digital automation to complete the job, and validating the output with another digital file.

Converters and brand-owners will now be able to rely on a new digital technology to protect their brand identities, and will benefit from major time savings and quality improvement benefits.

“A closed loop approach to color consistency is an extremely powerful concept and very interesting,” comments Alvise Cavallari from Nestlé. “If we can use process colors with a closed loop system, then we can ensure to achieve the stability and consistency that we need.”

“We want printing to go from an art to a science and to rely less on the influence of the operator,” agrees a Brand Owner from a global food company. “Having a digital file that we can calibrate and recreate anywhere in the world? This is the future. DigiColor could provide real competitive advantages. Now I want to see it proven for my brands.”

The future of color fidelity and consistency in product packaging – whether printed via flexo or digital inkjet – is bright. New innovations are ushering in the prospect of digitalized closed-loop systems and worldwide print consistency, with the speed and flexibility required in today’s high-pressure consumer environment.

For brand ownders, this brings reassurance their brand packaging will retain the full power and impact of the brand colors that they – and their consumers – are so invested in.