Greg Hrinya, Associate Editor03.13.17

Regardless of a brand’s prominence, industry experts agree that the role of labels and packaging go a long way toward conveying success. New trends in the flexible packaging space are leading the charge for many companies trying to distinguish themselves on the crowded shelves. In doing so, brands are utilizing new materials and new techniques to enhance their bottom lines.

John Howard, director of product management at Mark Andy, defines flexible packaging as a package that can change shape when filled with its contents. A flexible package’s construction often consists of paper, plastic film or metal foil. The packaging construction, which usually features printed graphics, is often seen in bags, pouches, wraparound labels, shrink or stretch sleeves, and lidding. The industry, he says, is growing at about 4% overall (7% for standup pouches).

“Most flexible packaging substrates are thermoplastic resins either cast or blown into thin substrates,” explains Howard. “Often, multiple resin types are co-extruded (cast) into a sandwich-like film with clearly distinct individual layers. Films may also be laminated after printing. Other substrates are metal foil and paper. A flexible package will usually be a multi-layer construction and each layer serves a particular purpose, such as tear resistance, barrier to substance migration, printable, heat sealable, vapor blocking or vapor transmissive, and more.”

According to Cindy Collins, flexible packaging business development manager at Avery Dennison, the segment is the second largest packaging sector at around 20%, with personal care and non-food retail account for roughly 10% of the market. “The trends we’re starting to see include industrial and hard-to-hold applications finding their way into the narrow web marketplace,” she says. “These constructions require a higher barrier and better performance than other segments of packaging.”

In addition, consumers are seeking single use and transparent packaging. “It’s convenient, but it’s also ease of use,” adds Collins.

Avery Dennison is focusing on hard-to-hold industrial applications, stickpacks, and its ChemControl Portfolio. “ChemControl is specifically designed to be highly chemical resistant and hold contents that tend to be much more aggressive,” says Collins. “It’s an area we’re continuing to focus on and grow.”

Flexible packaging requires printing inks, primers, coatings and adhesives. When dealing with foods, substrates, inks and adhesives need to meet specified substance migration levels. Howard adds that the majority of flexible packaging is printed on wide web central impression (CI) presses with solvent inks and two component solvent-free adhesive systems.

“We continue to see flexible packaging as the fastest growing market segment for narrow web,” says Paul Teachout, vice president of sales and marketing for Nilpeter USA. “There are a lot of trends and indicators that show there are no signs of a slowdown. The millennial generation is a big driver in this, as they are looking for faster, easier and better solutions. They want single serve, on-the-go packaging with sustainability in mind. The current packaging available offers viable alternatives to traditional rigid packaging. We are also seeing brand owners migrate toward these solutions due to their high market appeal and creative eye-catching designs.”

According to the Flexible Packaging Association (FPA), 80% of brand owners surveyed believe that packaging influences brand value. The FPA recently commissioned two studies – a Brand Value Study and a Transitioning Advantages Study – to better quantify how new technologies have impacted brands and consumers in the flexible packaging space.

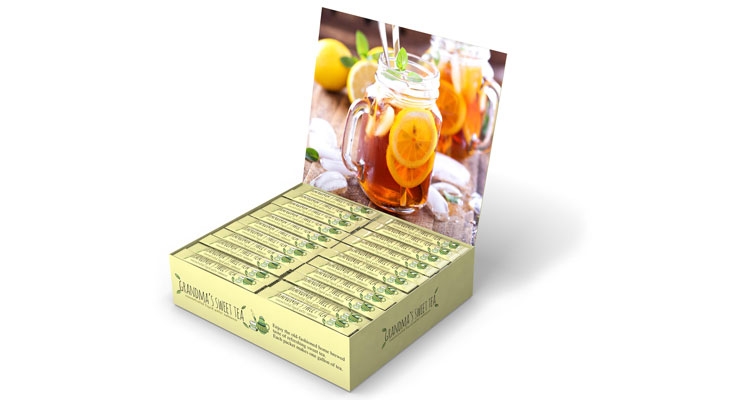

Flexible packaging is often utilized in the foods segment. CS Labels, a UK-based award-winning digital label manufacturer, sees many of its flexible packaging customers interested in stand-up pouches and sachets. Its food applications span dried fruits, granola, snacks and grains, as well as drinks like ground coffee and beans, leaf tea and teabags.

Alison Keane, FPA president and CEO, says that brands are seeking several attributes from their food packaging: reclosability, easy-to-open, and extended product shelf life. Also, the product must also be easy to store and carry. “One trend that is very apparent is that flexible packaging has gained popularity among consumers who are seeking packaging options that fit their on-the-go lifestyles,” she explains. “As for design and labeling, its impact on purchase decisions may not always be obvious, but 81% of the consumers polled stated that they ‘always,’ ‘often,’ or ‘sometimes’ notice when a product appears in new or different packaging. And when surveyed about food products, brand owners reported that enhancing brand image and differentiating the product on the shelf were the most important intangible factors to consider when assessing flexible packaging.”

Today’s packaging also strives to provide consumers with a better window into the product. Enhanced transparency allows a brand to showcase a product inside the packaging.

There are other trends in this space, as well. “There are two key requirements currently in the packaging industry: the need to extend shelf life and reduce food waste and for the consumer to be able to see the packaged product,” says Amaia Cowan, market development manager, Packaging, at Innovia Films. “To achieve both requirements, the industry needs to develop transparent materials with higher barrier levels to moisture and gases.”

“Flexible packaging no longer merely protects the product – it is now a key selling point and plays a crucial role during consumption,” explains Amanda Dahlby, marketing manager at Glenroy, Inc. “Packaging engineers are pressed to continuously develop new packages to meet consumers’ evolving demands.”

Press manufacturers offer a wide array of solutions for flexible packaging printers. Mark Andy’s equipment ranges from printing and laminating to inspecting, slitting and rewinding. Printing can be done with either Mark Andy’s Versa Max press or with its Performance Series line of presses. Versa Max is the wider of the two, up to 28", and has a rated speed of 1,200 fpm. The Performance Series is available in several widths up to 22" and has a rated speed of 1,000 fpm. Mark Andy also offers Rotoflex inspecting, slitting, and rewinding systems capable of operating up to 2,000 fpm.

Nilpeter offers a platform for every level of converter. The company has presses with fully automated web handling, temperature and tension management, as well as a full line of lamination and embellishment features to meet brand owners’ needs. Nilpeter’s FB line of presses ranges from 10", 13" and 16" while the FA line ranges from 17" to 22". According to Teachout, the FA line offers the highest level of servo automation in its class.

“Its not as simple as just running these materials on a traditional label press,” says Teachout. “The tensions, web preparation and temperature management are crucial. The press must have these systems to run productively and profitably.”

Converters have a wide range of materials available to them. According to Dahlby, flexible packaging structures typically consist of multiple layers of materials laminated together. These materials often include polyethylene, polypropylene, paper, foil, metalized polyester, nylon, ethylene acrylic acid, surlyn, metallocene, ethylene vinyl alchohol, and polyvinylidene chloride.

The benefits associated with each substrate vary, Dahbly explains, and different layers provide performance characteristics like oxygen, moisture or light resistance; chemical and puncture resistance; rigidity; and glossy or matte appearance, among others. “Our stocked ExpressWeb narrow web packaging films are engineered to accommodate a wide range of applications and markets,” shes says, adding, “We’re also able to custom-engineer films that meet specific performance requirements for narrow web printers. ExpressWeb films run reliably on presses and perform consistently even in challenging packaging applications.”

Innovia Films has been supplying films to the packaging industry for over 45 years, including its trademarked Propafilm. This product features a “bubble” process where films are produced with balanced orientation and properties. The company recently expanded its portfolio of peelable Biaxially Oriented Polypropylene (BOPP) films, featuring Propafilm RCP. Meanwhile, Propafilm SNC and NC are BOPP films with low heat-seal thresholds.

CS Labels uses a wide range of materials for its flexible packaging applications, including high-barrier substrates for more critical products. Other substrates include double or tri-laminate PET/PE films in metallic, clear, white and kraft paper constructions. “Our pouches are lightweight, use environmentally friendly inks, and they have an easy close and open mechanism,” says Simon Smith, managing director at CS Labels. “We also offer easy transportation and storage, and much more.”

CS Labels prints all of its pouches and sachets on a Xeikon 3500 digital label press, which is a toner-based digital print method designed to help with preventing migration and eliminating any impurities associated with other print methods.

Label Converters Adapt

According to Nilpeter, the flexible packaging market will generate $200 billion annually by 2020. “The North American market will represent 30% of this space,” says Paul Teachout. “With a growing level of consumer products, shorter runs and inline converting solutions, the narrow web label printer has a huge opportunity.

“We are seeing upwards of 40% of brand owners migrating to these solutions. It’s not a matter of if we should engage, but when we will need to. Shorter runs and higher levels of SKUs are more appealing to the narrow web market and this will push market share to our segment as wider web presses cannot offer a cost-effective solution,” Teachout explains.

Flexible packaging is attractive to the narrow web market for several reasons. Adds Teachout, “Today’s narrow web presses are capable of producing excellent low-tension regulation, low torque, low runout, balanced idlers, chilled driven rolls under hot air drying or UV curing, and inline solvent-free lamination.”

“Run lengths are getting shorter,” stresses Mark Andy’s Howard. “Wide web presses have learned how to gang short run jobs with expanded gamut, but there is opportunity for narrow web label press owners to profitably compete.”

According to All Printing Resources (APR), a small number of traditional label houses buy mid-web CI press for flexible packaging. In keeping with this trend, APR is commissioning a private research study in 2017 to examine label converters entering the flexible packaging space.

“We see more and more label converters entering the flexible packaging sector,” explains Dave Nieman, APR’s president and CEO. “These packaging companies are doing this primarily by printing and converting unsupported, flexible laminates on their narrow web flexo presses. Narrow web flexographic technology is at a point where its systems can effectively run very thin, unsupported (non-PS) films. As run sizes in the flexible packaging sector continue to contract, this opens up opportunities for label converters.”

Howard adds that narrow web presses are advantageous in terms of setup time, where a narrow web press will take 40 minutes compared to 90 minutes on wide web presses. Ink required to print the first impression (fill the system) is four gallons on narrow web compared to 25 gallons on wide web. He also explains that plates for an 8-color job on an 18" narrow web press cost about $260, while they run $1,500 on a 54" wide web press.

The flexible packaging space presents label converters with a new opportunity to expand their business. According to the FPA’s Keane, label companies are working closely with suppliers, brand owners and converters in the flexible packaging industry to introduce newer and more appealing packaging and designs.

From the converter perspective, CS Labels has seen increased demand from its clients as brands try to branch out and expand their offerings. “The pouch industry as a whole is experiencing exponential growth, and it’s unsurprising that label printers want to tap into that,” explains Smith. “The client not only needs a functioning product for food in multiple sorts/SKUs but also needs a company that can cope with volume, as well as speedy fulfillment and on-demand ordering based on client tastes and choices. Not a small undertaking, we can tell you. But we’ve done it well, won awards for it and then went from there. It has expanded rapidly ever since.”

Brands also want their packaging to feature synchronicity, where color, quality and customer service are predictable and repeatable. CS Labels has taken advantage of Xeikon’s color control to match colors throughout all of its presses. “Our clients know that whether they buy labels, or labels and pouches, or anything that we offer, we’ll ensure that everything harmonizes,” adds Smith. “We’re mindful of how great packaging can make a brand stand out on the shelf.”

Digital for flexible

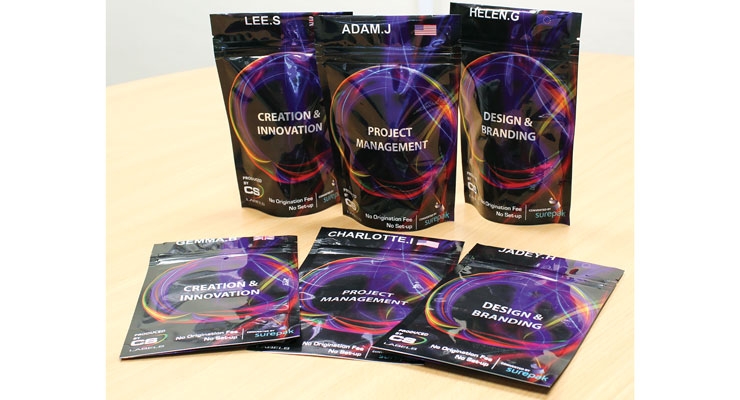

Digital printing offers certain capabilities for packaging that is not economical or feasible with traditional methods. CS Labels, with the help of Xeikon, prides itself on flexibility, special effects, personalization, versioning and variable data.

“Digital print is flexible in the sense that there are no plates – we can cater to multiple languages and SKUs without hassle, and it just fits in with our workflow,” explains Smith. “The packaging potential with pouches for any marketer is very apparent: digital offers personalization opportunities that can be cost prohibitive for other printing methods, such as including locale, various ranges, unique numbering for competitions/promotions, that are done inline during the print process – not afterwards.”

Avi Basu, director of marketing and business development, HP, says that digital printing has opened up new avenues, especially in flexible packaging. “What we see new and different in 2017 is the threshold for growth in flexible packaging,” he says. “We have an install base right now for our HP Indigo 20000 digital press, the early adopters, who have worked through some early issues and now understand the workflow, the substrates, coatings and everything else. Now they’re ready to take off and become more mainstream, and as that happens, other customers who are sitting in the pipeline are also going to make the jump. We do see a significant, higher annual growth rate coming from flexible packaging.”

The HP Indigo 20000 has the ability to run flexible packaging, labels, and shrink sleeves on film or paper. The press prints up to 135 linear fpm in full color at a 30" mid-web width. HP Indigo ElectroInk Premium White offers high-opacity white for heavy usage in a one-pass process.

Smart technology is increasingly being used in many flexible packaging applications, as well. For example, CS Labels currently offers products with Augmented Reality (AR), which provides an interactive experience for the consumer.

Challenges

According to Glenroy’s Dahlby, flexible packaging materials do not fit into a “one size fits all” category. There are a number of factors worth considering, including regulatory, cost, and aesthetic requirements, packaging equipment, product formulation, projected lifecycle and distribution methods. Dahlby says this can pose “a big challenge. Many product ingredients can interact with flexible packaging materials, creating adverse effects for both the product – such as chemical degradation – and the package, such as delamination,” Dahlby explains.

The challenges present throughout other segments of the print industry are seen in flexible packaging, as well. “The majority of flexible packaging in the United States is printed flexo and brands are demanding tighter and tighter tolerances with color reproduction and dot fades down to 0%,” says APR’s Nieman. “Job-to-job repeatability is one of the greatest production challenges both flexible packaging and label converters face in today’s industry. In order to meet shorter delivery times, presses are running at faster speeds and this makes precise color matching and dot control even more of a challenge.

Converters also must deal with wind tensions, which can present a flexible packaging challenge. “This is a crucial element in providing printed finished rolls with good roll conformation,” says Dahlby. “Good roll conformation is critical to ensuring that the material will perform properly at the next stage of converting, which involves the forming, filling and sealing of the pouches.”

“The demands on flexible packaging are always on the rise,” says Innovia Films’ Cowan. “As producers look at improving their products and efficiencies, the films have to protect more and run more efficiently while enticing the consumer further. To meet these challenges, Innovia Films works closely with its customers to understand what their specific needs and issues are.”

Live Long and Green

From the substrate supplier to the converter to the brand, all channels of the label and packaging industry are looking for ways to reduce waste and lower their carbon footprint.

“When assessing sustainability, examining the full lifecycle of a product/package is critical, and the overall lifecycle assessment of flexible packaging is exemplary,” says the FPA’s Keane. “Flexible packaging starts with using fewer resources and has the ability to package the most product in the least amount of packaging possible – positively impacting the energy use, GHG emissions, storage, transportation and waste going to landfill.”

According to Glenroy, flexible packaging utilizes approximately 60% less plastic than rigid plastic bottles while requiring about 50% less energy to produce. In addition, flexible packaging generates less CO2 emissions during production.

The Natural Resources Defense Council conducted a recent survey, citing up to 40% of food in the US is wasted. Flexible packaging, with more sustainable features, can help reduce waste. For example, bananas packaged in flexible packaging extended their shelf life from 15 to 36 days. Keane adds that a recent FPA survey showed 57% of brand owners said “less packaging waste” is a top sustainability goal. Meanwhile, only 31% of those surveyed said that the product should be “recyclable by the consumer.” Recyclability is a common goal for those brand owners surveyed.

According to the FPA, approximately 50% of flexible packaging waste is recyclable, with the other 50% available for energy recovery. Developing more end-of-life solutions continues to be a work-in-progress, and the initiative continues.

“Flexible packaging is lighter and packs denser than rigid packaging. This reduces shipping costs and reduces landfill waste,” says Mark Andy’s Howard. “For example, coffee brick packs compared to metal cans contains 88% less packaging weight, consumes 20% less space in shipping, reduces weight of waste-to-landfill by 72%, and would save over 17 million gallons of gasoline per year in manufacturing and transportation (by changing all steel cans to brick packs).”

John Howard, director of product management at Mark Andy, defines flexible packaging as a package that can change shape when filled with its contents. A flexible package’s construction often consists of paper, plastic film or metal foil. The packaging construction, which usually features printed graphics, is often seen in bags, pouches, wraparound labels, shrink or stretch sleeves, and lidding. The industry, he says, is growing at about 4% overall (7% for standup pouches).

“Most flexible packaging substrates are thermoplastic resins either cast or blown into thin substrates,” explains Howard. “Often, multiple resin types are co-extruded (cast) into a sandwich-like film with clearly distinct individual layers. Films may also be laminated after printing. Other substrates are metal foil and paper. A flexible package will usually be a multi-layer construction and each layer serves a particular purpose, such as tear resistance, barrier to substance migration, printable, heat sealable, vapor blocking or vapor transmissive, and more.”

According to Cindy Collins, flexible packaging business development manager at Avery Dennison, the segment is the second largest packaging sector at around 20%, with personal care and non-food retail account for roughly 10% of the market. “The trends we’re starting to see include industrial and hard-to-hold applications finding their way into the narrow web marketplace,” she says. “These constructions require a higher barrier and better performance than other segments of packaging.”

In addition, consumers are seeking single use and transparent packaging. “It’s convenient, but it’s also ease of use,” adds Collins.

Avery Dennison is focusing on hard-to-hold industrial applications, stickpacks, and its ChemControl Portfolio. “ChemControl is specifically designed to be highly chemical resistant and hold contents that tend to be much more aggressive,” says Collins. “It’s an area we’re continuing to focus on and grow.”

Flexible packaging requires printing inks, primers, coatings and adhesives. When dealing with foods, substrates, inks and adhesives need to meet specified substance migration levels. Howard adds that the majority of flexible packaging is printed on wide web central impression (CI) presses with solvent inks and two component solvent-free adhesive systems.

“We continue to see flexible packaging as the fastest growing market segment for narrow web,” says Paul Teachout, vice president of sales and marketing for Nilpeter USA. “There are a lot of trends and indicators that show there are no signs of a slowdown. The millennial generation is a big driver in this, as they are looking for faster, easier and better solutions. They want single serve, on-the-go packaging with sustainability in mind. The current packaging available offers viable alternatives to traditional rigid packaging. We are also seeing brand owners migrate toward these solutions due to their high market appeal and creative eye-catching designs.”

According to the Flexible Packaging Association (FPA), 80% of brand owners surveyed believe that packaging influences brand value. The FPA recently commissioned two studies – a Brand Value Study and a Transitioning Advantages Study – to better quantify how new technologies have impacted brands and consumers in the flexible packaging space.

Flexible packaging is often utilized in the foods segment. CS Labels, a UK-based award-winning digital label manufacturer, sees many of its flexible packaging customers interested in stand-up pouches and sachets. Its food applications span dried fruits, granola, snacks and grains, as well as drinks like ground coffee and beans, leaf tea and teabags.

Alison Keane, FPA president and CEO, says that brands are seeking several attributes from their food packaging: reclosability, easy-to-open, and extended product shelf life. Also, the product must also be easy to store and carry. “One trend that is very apparent is that flexible packaging has gained popularity among consumers who are seeking packaging options that fit their on-the-go lifestyles,” she explains. “As for design and labeling, its impact on purchase decisions may not always be obvious, but 81% of the consumers polled stated that they ‘always,’ ‘often,’ or ‘sometimes’ notice when a product appears in new or different packaging. And when surveyed about food products, brand owners reported that enhancing brand image and differentiating the product on the shelf were the most important intangible factors to consider when assessing flexible packaging.”

Today’s packaging also strives to provide consumers with a better window into the product. Enhanced transparency allows a brand to showcase a product inside the packaging.

There are other trends in this space, as well. “There are two key requirements currently in the packaging industry: the need to extend shelf life and reduce food waste and for the consumer to be able to see the packaged product,” says Amaia Cowan, market development manager, Packaging, at Innovia Films. “To achieve both requirements, the industry needs to develop transparent materials with higher barrier levels to moisture and gases.”

“Flexible packaging no longer merely protects the product – it is now a key selling point and plays a crucial role during consumption,” explains Amanda Dahlby, marketing manager at Glenroy, Inc. “Packaging engineers are pressed to continuously develop new packages to meet consumers’ evolving demands.”

Press manufacturers offer a wide array of solutions for flexible packaging printers. Mark Andy’s equipment ranges from printing and laminating to inspecting, slitting and rewinding. Printing can be done with either Mark Andy’s Versa Max press or with its Performance Series line of presses. Versa Max is the wider of the two, up to 28", and has a rated speed of 1,200 fpm. The Performance Series is available in several widths up to 22" and has a rated speed of 1,000 fpm. Mark Andy also offers Rotoflex inspecting, slitting, and rewinding systems capable of operating up to 2,000 fpm.

Nilpeter offers a platform for every level of converter. The company has presses with fully automated web handling, temperature and tension management, as well as a full line of lamination and embellishment features to meet brand owners’ needs. Nilpeter’s FB line of presses ranges from 10", 13" and 16" while the FA line ranges from 17" to 22". According to Teachout, the FA line offers the highest level of servo automation in its class.

“Its not as simple as just running these materials on a traditional label press,” says Teachout. “The tensions, web preparation and temperature management are crucial. The press must have these systems to run productively and profitably.”

Converters have a wide range of materials available to them. According to Dahlby, flexible packaging structures typically consist of multiple layers of materials laminated together. These materials often include polyethylene, polypropylene, paper, foil, metalized polyester, nylon, ethylene acrylic acid, surlyn, metallocene, ethylene vinyl alchohol, and polyvinylidene chloride.

The benefits associated with each substrate vary, Dahbly explains, and different layers provide performance characteristics like oxygen, moisture or light resistance; chemical and puncture resistance; rigidity; and glossy or matte appearance, among others. “Our stocked ExpressWeb narrow web packaging films are engineered to accommodate a wide range of applications and markets,” shes says, adding, “We’re also able to custom-engineer films that meet specific performance requirements for narrow web printers. ExpressWeb films run reliably on presses and perform consistently even in challenging packaging applications.”

Innovia Films has been supplying films to the packaging industry for over 45 years, including its trademarked Propafilm. This product features a “bubble” process where films are produced with balanced orientation and properties. The company recently expanded its portfolio of peelable Biaxially Oriented Polypropylene (BOPP) films, featuring Propafilm RCP. Meanwhile, Propafilm SNC and NC are BOPP films with low heat-seal thresholds.

CS Labels uses a wide range of materials for its flexible packaging applications, including high-barrier substrates for more critical products. Other substrates include double or tri-laminate PET/PE films in metallic, clear, white and kraft paper constructions. “Our pouches are lightweight, use environmentally friendly inks, and they have an easy close and open mechanism,” says Simon Smith, managing director at CS Labels. “We also offer easy transportation and storage, and much more.”

CS Labels prints all of its pouches and sachets on a Xeikon 3500 digital label press, which is a toner-based digital print method designed to help with preventing migration and eliminating any impurities associated with other print methods.

Label Converters Adapt

According to Nilpeter, the flexible packaging market will generate $200 billion annually by 2020. “The North American market will represent 30% of this space,” says Paul Teachout. “With a growing level of consumer products, shorter runs and inline converting solutions, the narrow web label printer has a huge opportunity.

“We are seeing upwards of 40% of brand owners migrating to these solutions. It’s not a matter of if we should engage, but when we will need to. Shorter runs and higher levels of SKUs are more appealing to the narrow web market and this will push market share to our segment as wider web presses cannot offer a cost-effective solution,” Teachout explains.

Flexible packaging is attractive to the narrow web market for several reasons. Adds Teachout, “Today’s narrow web presses are capable of producing excellent low-tension regulation, low torque, low runout, balanced idlers, chilled driven rolls under hot air drying or UV curing, and inline solvent-free lamination.”

“Run lengths are getting shorter,” stresses Mark Andy’s Howard. “Wide web presses have learned how to gang short run jobs with expanded gamut, but there is opportunity for narrow web label press owners to profitably compete.”

According to All Printing Resources (APR), a small number of traditional label houses buy mid-web CI press for flexible packaging. In keeping with this trend, APR is commissioning a private research study in 2017 to examine label converters entering the flexible packaging space.

“We see more and more label converters entering the flexible packaging sector,” explains Dave Nieman, APR’s president and CEO. “These packaging companies are doing this primarily by printing and converting unsupported, flexible laminates on their narrow web flexo presses. Narrow web flexographic technology is at a point where its systems can effectively run very thin, unsupported (non-PS) films. As run sizes in the flexible packaging sector continue to contract, this opens up opportunities for label converters.”

Howard adds that narrow web presses are advantageous in terms of setup time, where a narrow web press will take 40 minutes compared to 90 minutes on wide web presses. Ink required to print the first impression (fill the system) is four gallons on narrow web compared to 25 gallons on wide web. He also explains that plates for an 8-color job on an 18" narrow web press cost about $260, while they run $1,500 on a 54" wide web press.

The flexible packaging space presents label converters with a new opportunity to expand their business. According to the FPA’s Keane, label companies are working closely with suppliers, brand owners and converters in the flexible packaging industry to introduce newer and more appealing packaging and designs.

From the converter perspective, CS Labels has seen increased demand from its clients as brands try to branch out and expand their offerings. “The pouch industry as a whole is experiencing exponential growth, and it’s unsurprising that label printers want to tap into that,” explains Smith. “The client not only needs a functioning product for food in multiple sorts/SKUs but also needs a company that can cope with volume, as well as speedy fulfillment and on-demand ordering based on client tastes and choices. Not a small undertaking, we can tell you. But we’ve done it well, won awards for it and then went from there. It has expanded rapidly ever since.”

Brands also want their packaging to feature synchronicity, where color, quality and customer service are predictable and repeatable. CS Labels has taken advantage of Xeikon’s color control to match colors throughout all of its presses. “Our clients know that whether they buy labels, or labels and pouches, or anything that we offer, we’ll ensure that everything harmonizes,” adds Smith. “We’re mindful of how great packaging can make a brand stand out on the shelf.”

Digital for flexible

Digital printing offers certain capabilities for packaging that is not economical or feasible with traditional methods. CS Labels, with the help of Xeikon, prides itself on flexibility, special effects, personalization, versioning and variable data.

“Digital print is flexible in the sense that there are no plates – we can cater to multiple languages and SKUs without hassle, and it just fits in with our workflow,” explains Smith. “The packaging potential with pouches for any marketer is very apparent: digital offers personalization opportunities that can be cost prohibitive for other printing methods, such as including locale, various ranges, unique numbering for competitions/promotions, that are done inline during the print process – not afterwards.”

Avi Basu, director of marketing and business development, HP, says that digital printing has opened up new avenues, especially in flexible packaging. “What we see new and different in 2017 is the threshold for growth in flexible packaging,” he says. “We have an install base right now for our HP Indigo 20000 digital press, the early adopters, who have worked through some early issues and now understand the workflow, the substrates, coatings and everything else. Now they’re ready to take off and become more mainstream, and as that happens, other customers who are sitting in the pipeline are also going to make the jump. We do see a significant, higher annual growth rate coming from flexible packaging.”

The HP Indigo 20000 has the ability to run flexible packaging, labels, and shrink sleeves on film or paper. The press prints up to 135 linear fpm in full color at a 30" mid-web width. HP Indigo ElectroInk Premium White offers high-opacity white for heavy usage in a one-pass process.

Smart technology is increasingly being used in many flexible packaging applications, as well. For example, CS Labels currently offers products with Augmented Reality (AR), which provides an interactive experience for the consumer.

Challenges

According to Glenroy’s Dahlby, flexible packaging materials do not fit into a “one size fits all” category. There are a number of factors worth considering, including regulatory, cost, and aesthetic requirements, packaging equipment, product formulation, projected lifecycle and distribution methods. Dahlby says this can pose “a big challenge. Many product ingredients can interact with flexible packaging materials, creating adverse effects for both the product – such as chemical degradation – and the package, such as delamination,” Dahlby explains.

The challenges present throughout other segments of the print industry are seen in flexible packaging, as well. “The majority of flexible packaging in the United States is printed flexo and brands are demanding tighter and tighter tolerances with color reproduction and dot fades down to 0%,” says APR’s Nieman. “Job-to-job repeatability is one of the greatest production challenges both flexible packaging and label converters face in today’s industry. In order to meet shorter delivery times, presses are running at faster speeds and this makes precise color matching and dot control even more of a challenge.

Converters also must deal with wind tensions, which can present a flexible packaging challenge. “This is a crucial element in providing printed finished rolls with good roll conformation,” says Dahlby. “Good roll conformation is critical to ensuring that the material will perform properly at the next stage of converting, which involves the forming, filling and sealing of the pouches.”

“The demands on flexible packaging are always on the rise,” says Innovia Films’ Cowan. “As producers look at improving their products and efficiencies, the films have to protect more and run more efficiently while enticing the consumer further. To meet these challenges, Innovia Films works closely with its customers to understand what their specific needs and issues are.”

Live Long and Green

From the substrate supplier to the converter to the brand, all channels of the label and packaging industry are looking for ways to reduce waste and lower their carbon footprint.

“When assessing sustainability, examining the full lifecycle of a product/package is critical, and the overall lifecycle assessment of flexible packaging is exemplary,” says the FPA’s Keane. “Flexible packaging starts with using fewer resources and has the ability to package the most product in the least amount of packaging possible – positively impacting the energy use, GHG emissions, storage, transportation and waste going to landfill.”

According to Glenroy, flexible packaging utilizes approximately 60% less plastic than rigid plastic bottles while requiring about 50% less energy to produce. In addition, flexible packaging generates less CO2 emissions during production.

The Natural Resources Defense Council conducted a recent survey, citing up to 40% of food in the US is wasted. Flexible packaging, with more sustainable features, can help reduce waste. For example, bananas packaged in flexible packaging extended their shelf life from 15 to 36 days. Keane adds that a recent FPA survey showed 57% of brand owners said “less packaging waste” is a top sustainability goal. Meanwhile, only 31% of those surveyed said that the product should be “recyclable by the consumer.” Recyclability is a common goal for those brand owners surveyed.

According to the FPA, approximately 50% of flexible packaging waste is recyclable, with the other 50% available for energy recovery. Developing more end-of-life solutions continues to be a work-in-progress, and the initiative continues.

“Flexible packaging is lighter and packs denser than rigid packaging. This reduces shipping costs and reduces landfill waste,” says Mark Andy’s Howard. “For example, coffee brick packs compared to metal cans contains 88% less packaging weight, consumes 20% less space in shipping, reduces weight of waste-to-landfill by 72%, and would save over 17 million gallons of gasoline per year in manufacturing and transportation (by changing all steel cans to brick packs).”