Greg Hrinya, Associate Editor11.16.18

112 Commerce Drive,

Nicholasville, KY, USA

www.turnerlabels.com

In 1967, Bob Turner took a risk that is still paying dividends today. Turner envisioned a great opportunity in printing, so he decided to start his own business. He focused primarily on business forms before turning to labels and shipping supplies. That small operation has evolved into a thriving label converting business, which calls the greater Lexington, KY area home.

Turner, a pioneer in the label printing business, emerged as one of the industry’s pre-eminent problem solvers. He traveled the world, from Cincinnati to China, to find the best and most efficient converting techniques. His work ethic blossomed from an early age, as he gained employment at age 15.

“He was always traveling somewhere, and he could always solve the problem, no matter what,” exclaims Barb Turner, Bob’s wife and current chairwoman and majority owner of Turner Labels. “It was amazing. He would not quit until he solved the problem.”

“He was the man,” says Stephen Turner, CEO of Turner Labels and Bob’s son. “I don’t want to say he micromanaged because he just knew everything. When we’d go to Labelexpo, everyone would know him, and I’m talking about the biggest of the big companies. They would all know who he was. He would literally go to the moon if there was a solution.”

Stephen grew up with the company, as he worked his way up the ranks. At 18, he began working as a janitor at Turner Labels. He would go on to run a printing press, work in sales and handle the deposit. Stephen was a sponge, absorbing the various working styles of the employees and his father. He learned much of the business through his father’s long meetings, which were described like “the senate and the house.”

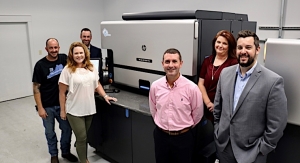

Bob passed away in 2014 following a sudden illness, and the company has been committed to running Turner Labels in his honor. Stephen assumed leadership as the CEO, and he works alongside Jeremy Brooking, CFO, Sherry Callahan, COO, J.D. Dickey, VP of business development, and Mike Jewel, VP of operations. Turner Labels operates out of its Nicholasville, KY location, where Bob relocated to in the mid-1980s.

Although well-groomed in the family business, Stephen needed to acclimate himself to a leadership role in a hurry. “I was probably 50% prepared, but nobody’s prepared for that situation when your dad is such a huge part of the business,” says Stephen. “I was more ready than people thought because I had been around him.”

Stephen also had the opportunity to spend a considerable amount of time at labels and packaging functions. He grew up around TLMI, starting around the age of 14. The company has also been active in the FTA and regularly attends Labelexpo. Stephen has his sights set on drupa 2020, as well.

A strong foundation

Turner Labels, which has a staff of 25 employees, offers multiple value-added services under one roof. In addition to a customer service team and sales department, Turner Labels provides in-house flexo and digital prepress, platemaking, a graphic design division, and a marketing team. Press operators, rewind and shipping departments also comprise the dedicated staff.

“I think once you keep your operations in house, you’ve got total control of everything,” says Brooking. “You’re not outsourcing plates, you’re not outsourcing design, and you know where your jobs stand every step of the way. From an efficiency standpoint, it helps.”

Turner Labels has historically found success in flexographic printing, having several Mark Andy 2200 presses, three Mark Andy 830s, and a Mark Andy 4150. The company boasts a Newfoil press for hot-stamping, too.

Turner Labels has also embraced many print markets, choosing not to limit itself, as its applications run the gamut from wine and spirits to durable labels. “If we say we do high-end labels, then nobody’s going to give us the warning labels, and then if we say we do warning labels, they’re going to say, ‘Oh you just do stickers, you don’t do wine and other high-end labels’,” explains Stephen. “We want people to understand that what we’re doing is cutting-edge. We’re doing liquor labels but we’re also running cosmetic labels.”

The company prides itself on a responsive customer service department, operating with what Brooking defines as a “proactive and not reactive relationship” with its customers. According to Callahan, customers don’t get a voicemail when they call Turner Labels, they reach a person.

“We have a small business mentality,” says Stephen. “We treat our customers like family, and a lot of them will actually invite us places on weekends. At the end of the day, you have to care about your customers because you spend more time at work than anywhere else. You want to be able to talk to somebody about shared interests, like sports or music, and we really try to do that.”

These relationships have built a strong foundation at Turner Labels. “Whenever someone calls they know who they want to talk to,” explains Audrey Burnett, marketing coordinator at Turner Labels. “They’re not just calling Turner Labels, they’re calling Sherry or Kristen, and they know by name who they’re coming to talk to. They know their sales person’s name, they know their graphic designer, and they know exactly who they’re working with here. They’re not just working with some faceless person they’ve been bounced around from.”

Stephen has fostered a diverse work environment, as well. There are employees who have lengthy tenures, while Turner also values the next generation of workers. “I want a mix of employees,” he says. “I want the young, up-and-coming generation and I want the older, more experienced and seasoned employees. When I took over, there were dad’s people and not many of mine, so I had to blend. We lost some good people and added some strong people, and I had to come up with my own team.”

‘All-in’ with HP

In building the business for the next generation, Stephen Turner followed in his father’s footsteps with another big gamble. As Bob took a risk on printing labels, Stephen decided to take a chance on digital printing.

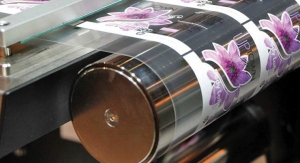

By perceiving digital label printing as the next step in building the company’s brand, Turner Labels recently invested in the new HP Indigo 6900 digital press. The company recognized its ability to provide more solutions for its customers while also expanding into new arenas. Turner Labels has seen an increase in demand for multiple SKUs and shorter runs, especially in industries that range from local distilleries to hemp.

The HP Indigo 6900 digital press runs at up to 98 fpm in 4-color mode and 130 fpm in Enhanced Productivity Mode. In 1- or 2-color mode, the press can print at 196 fpm.

“For us, it was the future,” explains Brooking. “There are countless applications, and we don’t want to narrow our focus and only explore one label segment because there are so many industries we print labels for, like nutraceuticals, pharmaceuticals and more. We noticed a trend, where you get an order of 10 different jobs of a couple thousand labels each. It just made sense for us to not set up plates for every single job.”

The HP Indigo 6900 press opens up avenues beyond pressure sensitive labels, including shrink sleeves, in-mold and flexible packaging. HP’s product support services also played a large role.

“We did a lot of due diligence on the HP press,” says Stephen. “For me, it was all about the support. They’ve got the business development piece there where if you’re not growing with HP, they’re not making the money that they want to make. The support was strong and the quality was very good. It was more in line with what we see on our flexo side than some of the digital inkjet providers.”

In addition, Stephen notes the pop provided on the labels. “At the end of the day, why is somebody going to buy a product? I can’t tell you how many times I’ve bought a product because the label looks good,” he says. “It’s the pop, and HP has the pop. They have the swag in the industry. I’m not going to buy a label and say, ‘That looks really efficient.’ It has to pop, and that was HP the whole way.”

Bob Turner explored several digital avenues, but none of them were viable for the company. When Stephen assumed control of Turner Labels, he realized he would be faced with several difficult decisions – including whether or not to invest in a major digital production press. For a small company such as Turner, this emerged as a key decision.

“This is a big risk on my part, and I’m not sure if my dad would have made it,” says Stephen. “The one thing people always do when they take over a business as second generation is ask, ‘Am I going to sell? Do I want to go through all this because I saw my dad go through all the stress,’ and I struggled with that in the beginning?

“But then eventually I got the answer that I wanted. I’m a big faith person and I prayed about it, I talked to some people and I decided that I’m all-in. Well, this is the biggest all-in thing I could do with this HP press because it’s the future.

“You have to gamble big,” he adds. “It’s a risk, but what’s the point if you just play it safe?”

Enjoying the journey

Even though Turner Labels is a smaller converter, the company has lofty goals for the future that include enhanced quality, possible expansion and continued investment in its people. For Stephen, enjoying the process is all part of Turner’s success.

“I just want to be able to have fun,” he says. “Everyone wants more money and the normal ABC things, but I just want to have fun and go along with the industry, not being left behind just because we’re small. I want to ride with the industry. Nobody started big. They all started small, and I just want to take calculated risks.”

Already a global supplier, Turner Labels is seeking an expanded presence in new territories. In addition to having a strong network in the greater Lexington area, the company is looking to grow. Turner Labels, who owns the land at the Nicholasville facility, also owns the land in the vacated area next to the building.

“We have the room, and a lot of people in the industry that are bigger than us covet our room,” says Stephen. “Do I want to see a building next door? Sure. But I want to see it for the right reasons. I don’t just want to say, ‘Well, we have the land, so we might as well put a building on it so we can tell our buddies.’ Nobody cares about that.

“We want to have fun and enjoy the journey,” Stephen concludes. “At the end of the day, it doesn’t matter how much money you have. I mean, I could say my goal is to make a zillion dollars, but if you’re not enjoying the ride and you’re just checking boxes, what fun is that? If my employees are happy and well taken care of, and I’m having fun and they’re having fun, what more do you want? Seeing my employees happy and me having peace – that’s all I want.”

Nicholasville, KY, USA

www.turnerlabels.com

In 1967, Bob Turner took a risk that is still paying dividends today. Turner envisioned a great opportunity in printing, so he decided to start his own business. He focused primarily on business forms before turning to labels and shipping supplies. That small operation has evolved into a thriving label converting business, which calls the greater Lexington, KY area home.

Turner, a pioneer in the label printing business, emerged as one of the industry’s pre-eminent problem solvers. He traveled the world, from Cincinnati to China, to find the best and most efficient converting techniques. His work ethic blossomed from an early age, as he gained employment at age 15.

“He was always traveling somewhere, and he could always solve the problem, no matter what,” exclaims Barb Turner, Bob’s wife and current chairwoman and majority owner of Turner Labels. “It was amazing. He would not quit until he solved the problem.”

“He was the man,” says Stephen Turner, CEO of Turner Labels and Bob’s son. “I don’t want to say he micromanaged because he just knew everything. When we’d go to Labelexpo, everyone would know him, and I’m talking about the biggest of the big companies. They would all know who he was. He would literally go to the moon if there was a solution.”

Stephen grew up with the company, as he worked his way up the ranks. At 18, he began working as a janitor at Turner Labels. He would go on to run a printing press, work in sales and handle the deposit. Stephen was a sponge, absorbing the various working styles of the employees and his father. He learned much of the business through his father’s long meetings, which were described like “the senate and the house.”

Bob passed away in 2014 following a sudden illness, and the company has been committed to running Turner Labels in his honor. Stephen assumed leadership as the CEO, and he works alongside Jeremy Brooking, CFO, Sherry Callahan, COO, J.D. Dickey, VP of business development, and Mike Jewel, VP of operations. Turner Labels operates out of its Nicholasville, KY location, where Bob relocated to in the mid-1980s.

Although well-groomed in the family business, Stephen needed to acclimate himself to a leadership role in a hurry. “I was probably 50% prepared, but nobody’s prepared for that situation when your dad is such a huge part of the business,” says Stephen. “I was more ready than people thought because I had been around him.”

Stephen also had the opportunity to spend a considerable amount of time at labels and packaging functions. He grew up around TLMI, starting around the age of 14. The company has also been active in the FTA and regularly attends Labelexpo. Stephen has his sights set on drupa 2020, as well.

A strong foundation

Turner Labels, which has a staff of 25 employees, offers multiple value-added services under one roof. In addition to a customer service team and sales department, Turner Labels provides in-house flexo and digital prepress, platemaking, a graphic design division, and a marketing team. Press operators, rewind and shipping departments also comprise the dedicated staff.

“I think once you keep your operations in house, you’ve got total control of everything,” says Brooking. “You’re not outsourcing plates, you’re not outsourcing design, and you know where your jobs stand every step of the way. From an efficiency standpoint, it helps.”

Turner Labels has historically found success in flexographic printing, having several Mark Andy 2200 presses, three Mark Andy 830s, and a Mark Andy 4150. The company boasts a Newfoil press for hot-stamping, too.

Turner Labels has also embraced many print markets, choosing not to limit itself, as its applications run the gamut from wine and spirits to durable labels. “If we say we do high-end labels, then nobody’s going to give us the warning labels, and then if we say we do warning labels, they’re going to say, ‘Oh you just do stickers, you don’t do wine and other high-end labels’,” explains Stephen. “We want people to understand that what we’re doing is cutting-edge. We’re doing liquor labels but we’re also running cosmetic labels.”

The company prides itself on a responsive customer service department, operating with what Brooking defines as a “proactive and not reactive relationship” with its customers. According to Callahan, customers don’t get a voicemail when they call Turner Labels, they reach a person.

“We have a small business mentality,” says Stephen. “We treat our customers like family, and a lot of them will actually invite us places on weekends. At the end of the day, you have to care about your customers because you spend more time at work than anywhere else. You want to be able to talk to somebody about shared interests, like sports or music, and we really try to do that.”

These relationships have built a strong foundation at Turner Labels. “Whenever someone calls they know who they want to talk to,” explains Audrey Burnett, marketing coordinator at Turner Labels. “They’re not just calling Turner Labels, they’re calling Sherry or Kristen, and they know by name who they’re coming to talk to. They know their sales person’s name, they know their graphic designer, and they know exactly who they’re working with here. They’re not just working with some faceless person they’ve been bounced around from.”

Stephen has fostered a diverse work environment, as well. There are employees who have lengthy tenures, while Turner also values the next generation of workers. “I want a mix of employees,” he says. “I want the young, up-and-coming generation and I want the older, more experienced and seasoned employees. When I took over, there were dad’s people and not many of mine, so I had to blend. We lost some good people and added some strong people, and I had to come up with my own team.”

‘All-in’ with HP

In building the business for the next generation, Stephen Turner followed in his father’s footsteps with another big gamble. As Bob took a risk on printing labels, Stephen decided to take a chance on digital printing.

By perceiving digital label printing as the next step in building the company’s brand, Turner Labels recently invested in the new HP Indigo 6900 digital press. The company recognized its ability to provide more solutions for its customers while also expanding into new arenas. Turner Labels has seen an increase in demand for multiple SKUs and shorter runs, especially in industries that range from local distilleries to hemp.

The HP Indigo 6900 digital press runs at up to 98 fpm in 4-color mode and 130 fpm in Enhanced Productivity Mode. In 1- or 2-color mode, the press can print at 196 fpm.

“For us, it was the future,” explains Brooking. “There are countless applications, and we don’t want to narrow our focus and only explore one label segment because there are so many industries we print labels for, like nutraceuticals, pharmaceuticals and more. We noticed a trend, where you get an order of 10 different jobs of a couple thousand labels each. It just made sense for us to not set up plates for every single job.”

The HP Indigo 6900 press opens up avenues beyond pressure sensitive labels, including shrink sleeves, in-mold and flexible packaging. HP’s product support services also played a large role.

“We did a lot of due diligence on the HP press,” says Stephen. “For me, it was all about the support. They’ve got the business development piece there where if you’re not growing with HP, they’re not making the money that they want to make. The support was strong and the quality was very good. It was more in line with what we see on our flexo side than some of the digital inkjet providers.”

In addition, Stephen notes the pop provided on the labels. “At the end of the day, why is somebody going to buy a product? I can’t tell you how many times I’ve bought a product because the label looks good,” he says. “It’s the pop, and HP has the pop. They have the swag in the industry. I’m not going to buy a label and say, ‘That looks really efficient.’ It has to pop, and that was HP the whole way.”

Bob Turner explored several digital avenues, but none of them were viable for the company. When Stephen assumed control of Turner Labels, he realized he would be faced with several difficult decisions – including whether or not to invest in a major digital production press. For a small company such as Turner, this emerged as a key decision.

“This is a big risk on my part, and I’m not sure if my dad would have made it,” says Stephen. “The one thing people always do when they take over a business as second generation is ask, ‘Am I going to sell? Do I want to go through all this because I saw my dad go through all the stress,’ and I struggled with that in the beginning?

“But then eventually I got the answer that I wanted. I’m a big faith person and I prayed about it, I talked to some people and I decided that I’m all-in. Well, this is the biggest all-in thing I could do with this HP press because it’s the future.

“You have to gamble big,” he adds. “It’s a risk, but what’s the point if you just play it safe?”

Enjoying the journey

Even though Turner Labels is a smaller converter, the company has lofty goals for the future that include enhanced quality, possible expansion and continued investment in its people. For Stephen, enjoying the process is all part of Turner’s success.

“I just want to be able to have fun,” he says. “Everyone wants more money and the normal ABC things, but I just want to have fun and go along with the industry, not being left behind just because we’re small. I want to ride with the industry. Nobody started big. They all started small, and I just want to take calculated risks.”

Already a global supplier, Turner Labels is seeking an expanded presence in new territories. In addition to having a strong network in the greater Lexington area, the company is looking to grow. Turner Labels, who owns the land at the Nicholasville facility, also owns the land in the vacated area next to the building.

“We have the room, and a lot of people in the industry that are bigger than us covet our room,” says Stephen. “Do I want to see a building next door? Sure. But I want to see it for the right reasons. I don’t just want to say, ‘Well, we have the land, so we might as well put a building on it so we can tell our buddies.’ Nobody cares about that.

“We want to have fun and enjoy the journey,” Stephen concludes. “At the end of the day, it doesn’t matter how much money you have. I mean, I could say my goal is to make a zillion dollars, but if you’re not enjoying the ride and you’re just checking boxes, what fun is that? If my employees are happy and well taken care of, and I’m having fun and they’re having fun, what more do you want? Seeing my employees happy and me having peace – that’s all I want.”