Greg Hrinya, Associate Editor04.05.19

In today’s label and package printing market, flexibility is not limited to presses and substrates. Flexible dies are becoming increasingly popular among converters, especially as suppliers continue to make flexo tooling more efficient and cost-effective.

Flexible dies offer several inherent advantages over solid tooling. Top benefits include short turnaround times, low shipping costs and reduced storage requirements.

“The main reason for the shift to flexible dies is economical,” says Wade Fouts, VP of sales at Wilson Manufacturing. “Flexible dies can provide financial savings, faster availability and require less room for storage.”

“When also taking into account the accuracy and repeatability of a flexible die, as well as the die life now achievable and the wide range of materials that can be converted, it is easy to see why they ideally match the needs of today’s converters,” says David Morris, president and CEO of Kocher + Beck USA. “With the exception of overall material thickness, there are few limitations that prevent a user from using a flexible die.”

Flexible dies can handle PP, PE, PVT, PET, Tyvek, card stocks and more. “As all of Kocher + Beck’s flexible dies are machine sharpened, cutting angles and die heights are adjusted to accommodate specific material constructions and requirements,” adds Morris. “This means that we are able to convert a wide range of self-adhesive and single material substrates.”

Sinkotech sees all roll-to-roll substrates as effective. Rigidity of the material can be a factor in reducing the success rate of flexible dies, however. Cutting is done by dipping the blades into the material, so the material should have some flexibility. Some rigid materials, such as thick PET, need to be punch converted.

Keith Laakko, vice president of global marketing and business development at RotoMetrics, a Maxcess brand, states that the list of materials that are compatible with flexible dies is constantly expanding.

According to Laakko, magnetic cylinders have played a pivotal role in the rise of flexible die usage. “Originally designed for quick changes and shorter runs, new technology has flexible dies running longer and on a wider variety of materials, increasing their value for converters,” says Laakko. “Magnetic cylinders allow for multiple variations in shapes, sizes, and label repeats, making them the most versatile option available. Combine flexible dies on magnetic cylinders, with adjustable anvils allowing for material variance, and now the possibilities are endless.

“High tolerance magnetic cylinders, combined with the elite technology of our flexible dies, allow for new levels of precision,” he adds.

In addition, pressure monitoring systems allow converters to monitor and improve performance metrics for consistency and repeatability. Anvil rolls result in an improved cut edge and longer die life, with custom features available such as adjustable clearance. With an adjustable clearance anvil, converters will compensate for liner variance, or change to a different liner without removing the die, or just utilize inventory tools made previously for a different liner thickness, notes Laakko.

According to Andre Gysbers, marketing director at Wink, a flawless condition of all components in the diecutting station, including cylinders, is crucial for successful diecutting. “To achieve optimum diecutting results, converters need high-quality magnetic cylinders,” he says. “Our magnetic cylinders are the perfect complement to our SuperCut dies. They come with extra-strong adhesion, stainless steel and minimum tolerances. Moreover, the bearer rings can be dismantled and reworked separately, making them very cost-effective.”

Flexible die technology will continue to evolve, too. In the future, converters can expect to see thinner film substrates and liners and faster turnaround times, especially as customers continue to look for increased performance and decreased downtime.

In fact, RotoMetrics can turn around an order on the same day as purchase. “With fast turnaround times, lower investment costs for tooling, freight and storage, the flexible die is the perfect tool for this exploding market segment,” says Laakko. “RotoMetrics consistently ships dies on a 24-hour schedule. Flexible dies within common specifications can be ordered and shipped the same day.”

Ideal for digital

Short runs are the hallmark of digital printing. The ability to offer flexible dies for short turnaround times makes these products ideally suited for the digital printing market.

“The digital label printing market operates on a very short turn time, and therefore requires tooling that can support such time restraints,” says Kocher + Beck’s Morris. “Flexible dies are ideally suited to this, and Kocher + Beck has focused on its internal investments, allowing it to reduce production times and offer short deliver times. With the availability of same day shipping of dies, a digital label printer has the possibility of producing product less than 24 hours after submitting the flexible die order.”

Morris adds that within the digital area of the market, converting speeds will continue to increase with the introduction of newer high speed equipment.

Sinkotech notes that flexible dies and digital printing follow a similar model: Flexible dies are economical and easy to switch from one job to another just like digital printing jobs.

While Wink has seen an increased trend toward laser diecutting for digital jobs, many customers still opt for conventional diecutting because of the wide range of material choices and investments costs.

“We see a strong trend toward short-run digital printing, and overall this affects our business positively, as every different job needs its own unique cutting tool,” says Wink’s Gysbers. “The majority of digital labels comes with rather simple shapes, which enables us to produce and ship the required dies very quickly and cost-effectively.”

New products

With the demand for flexible dies rising, industry suppliers have developed a host of new products to further simplify the diecutting process.

Kocher + Beck, whose core products are manufactured and shipped out of Lenexa, KS, USA, offers a comprehensive range of flexible dies. The company’s expansive portfolio is designed to meet the needs of customers in all market segments. Kocher + Beck’s Universal die is ideal for short-to-medium run lengths and converts materials ranging from PP and PE to PET and card stocks.

For longer run lengths, the company’s 3L (Laser Long Life) is an appropriate choice, incorporating the use of a laser to harden the tip of the cutting blade. This allows the die to remain flexible while increasing the durability of the cutting line. According to Morris, additional coatings and treatments are also available, such as the GlueX coating to prevent adhesive build up, or its Chrome coating, which increases die life when converting thermal transfer materials and aggressive inks.

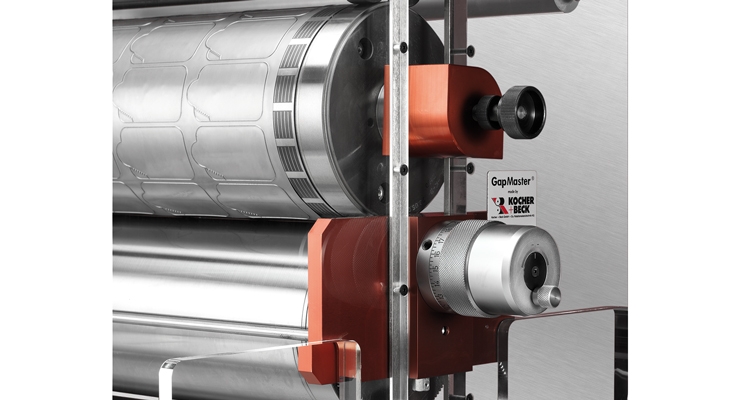

“On our flexible dies, we have invested significantly in our production processes and equipment to allow us to produce an extremely high-quality tight tolerance die as standard while also focusing on reducing the production time required to meet the needs of our customers,” says Morris. “We were also the first to bring the Gapmaster adjustable anvil product to the market, giving converters an extremely fine level of control range over their diecutting, something that is extremely important when cutting down to the thin PET liners.”

Kocher + Beck produces flexible dies, magnetic cylinders, anvil cylinders, hot stamps and rotary screen material, as well as end rings out of its Lenexa, KS facility. With additional products offered out if its’ headquarters in Germany to meet customers’ needs.

RotoMetrics provides a complete line of flexible dies for converting applications, ranging from simple papers to challenging thin films and even abrasive materials. The company’s completely integrated solutions, which include dies, magnetic cylinders, anvils and more, are important, as all variables that impact the converting process must be considered in a print job.

By acquiring Electro Optic, RotoMetrics furthered its portfolio of flexible die technologies. RotoMetrics now offers proprietary manufacturing processes with Electro Optic’s exclusive technologies, particularly as they relate to automating processes, coating processes and blade technologies, combining the best of both organizations. “This combination resulted in unprecedented industry improvements in flexible die consistency, blade levelness, durability and longevity,” says RotoMetrics’ Laakko. “Our flexible dies equip converters with elite technology to do things they just couldn’t do before. We are converting thinner films faster and more abrasive materials longer than ever.”

RotoMetrics’ development of exclusive coatings and treatments has positively impacted press performance. “For over 60 years now, RotoMetrics has built relationships with our customers, listening to their needs and developing innovative solutions for their converting challenges,” adds Laakko.

Sinkotech prides itself on excellent and dynamic customer service, product value and fast solutions for any cutting problem. “Our target is to be the best solution partnership,” the company says.

Sinkotech has utilized several techniques to improve the performance of its flexible dies. “We do not use any heavy metals, such as chrome, to make our dies look shiny or last longer because such coatings create rounded tips, causing failure when cutting film against thin liners,” the company says. “For this reason, our flexible dies’ appearance is not shiny, but maintains sharp tips, and our long-life dies are also achieved without such coatings.”

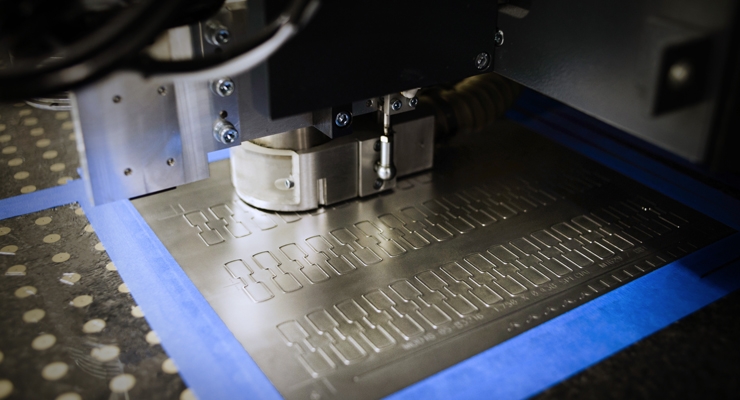

Wilson’s flexible cutting dies combine the benefits of performance plus cost savings – all in one product, the company says. Wilson’s dies start from hardened spring steel and utilize computer-to-plate technology, chemical etching and machine sharpening. “We offer a variety of dies that are application specific,” explains Wilson’s Fouts. “This includes Flex Pro, Flex Pro-film, Flex Film Extreme, Flex Extreme and Flex Anti-adhesive.” Wilson holds numerous patents, including its proprietary premium, fully hardened, machine-sharpened dies. “In August of 2018, we moved into a new state-of-the-art facility, fully-equipped with the latest equipment and technology for Lean, high-quality manufacturing,” adds Fouts.

Wink offers a comprehensive range of premium quality flexible dies. Wink’s SuperCut dies cover all kinds of label and narrow web applications, and each SuperCut die is adapted to customers’ requirements using the latest CNC technology. Special surface treatments significantly increase the service life of the tools, notes Wink’s Gysbers. These finishings include laser hardening, MCR MicroChrome coating for extreme long runs and abrasive materials, as well as four different non-stick coatings that minimize the adhesion of adhesive and paint residues.

“Our range of flexible dies is accompanied by all types of rotary cylinders, including solid dies, magnetic, printing, sheeting and anvil cylinders, the SmartGap adjustable anvil system, diecutting stations and pressure gauges,” says Gysbers. “All our dies are cut by laser, which not only guarantees perfectly parallel edges, but also minimizes the risk of injury. And our range of blade geometries is unique and offers the best cutting results for any application.”

Aztec Label, a narrow web tradehouse located in the UK, is installing AccuStrike anvils on each of its three Nilpeter FB presses at its production facility in Kidderminster as part of an ongoing program of investment in production efficiency. The new equipment is RotoMetrics’ answer to die wear and the problems posed by some of today’s tricky filmic substrates.

Founded in 1993 by Colin Le Gresley and now employing 25 staff, the company offers label printing in up to 10 colors on its dual water-based/UV press lines. A RotoMetrics user from day one, Aztec buys all its flexible and solid dies from the Aldridge-based supplier, and according to Le Gresley, a number of bespoke parts too. “The depth of knowledge at RotoMetrics is second to none – they even rebuilt a gear-train on a print cylinder for us a few years back, and we now send all of our operators on their training courses, so they understand the science behind the technology and learn good tool management skills,” he explains.

The new AccuStrike anvils will offer a high degree of die adjustability to the press operators. A simple drop-in installation, the new anvils require no modification to the existing die tool inventory, but by allowing movement of the bearers, either independently or together, the accuracy of die strike across the full web can be maintained. This prolongs die life and reduces cycle times with the resulting lower replacement cost and is all part of Colin Le Gresley’s drive to improve the operational environment and drive up productivity.

“I saw first hand how AccuStrike improved the performance of flexible dies on the press, so now we need to educate our operators to a new way of thinking and setting the tool. I’m a firm believer in investing for efficiency and improving the working environment – it’s sound financial planning for the future and saves the extra cost of trying to play catch-up later,” he adds. Aztec Label will produce sales of around £3m this year, with a target of £4m to take the company to the next stage. Having purchased and converted a 15,000 square foot facility back in 2015 that now offers a state-of-the-art production and admin setup, there is little doubt that Colin Le Gresley has a clear vision for the company’s future. This includes a policy of positive recruitment from the younger age group who will soon need to take on the roles of staff that has been with Aztec since the beginning.

“We offer a quality service to our customers and need the best equipment to do so – but even that’s no use without first class support and service from our suppliers to back it up. RotoMetrics ticks both boxes for us, and the new AccuStrike technology will make a significant difference our diecutting efficiency,” he concludes.

Flexible dies offer several inherent advantages over solid tooling. Top benefits include short turnaround times, low shipping costs and reduced storage requirements.

“The main reason for the shift to flexible dies is economical,” says Wade Fouts, VP of sales at Wilson Manufacturing. “Flexible dies can provide financial savings, faster availability and require less room for storage.”

“When also taking into account the accuracy and repeatability of a flexible die, as well as the die life now achievable and the wide range of materials that can be converted, it is easy to see why they ideally match the needs of today’s converters,” says David Morris, president and CEO of Kocher + Beck USA. “With the exception of overall material thickness, there are few limitations that prevent a user from using a flexible die.”

Flexible dies can handle PP, PE, PVT, PET, Tyvek, card stocks and more. “As all of Kocher + Beck’s flexible dies are machine sharpened, cutting angles and die heights are adjusted to accommodate specific material constructions and requirements,” adds Morris. “This means that we are able to convert a wide range of self-adhesive and single material substrates.”

Sinkotech sees all roll-to-roll substrates as effective. Rigidity of the material can be a factor in reducing the success rate of flexible dies, however. Cutting is done by dipping the blades into the material, so the material should have some flexibility. Some rigid materials, such as thick PET, need to be punch converted.

Keith Laakko, vice president of global marketing and business development at RotoMetrics, a Maxcess brand, states that the list of materials that are compatible with flexible dies is constantly expanding.

According to Laakko, magnetic cylinders have played a pivotal role in the rise of flexible die usage. “Originally designed for quick changes and shorter runs, new technology has flexible dies running longer and on a wider variety of materials, increasing their value for converters,” says Laakko. “Magnetic cylinders allow for multiple variations in shapes, sizes, and label repeats, making them the most versatile option available. Combine flexible dies on magnetic cylinders, with adjustable anvils allowing for material variance, and now the possibilities are endless.

“High tolerance magnetic cylinders, combined with the elite technology of our flexible dies, allow for new levels of precision,” he adds.

In addition, pressure monitoring systems allow converters to monitor and improve performance metrics for consistency and repeatability. Anvil rolls result in an improved cut edge and longer die life, with custom features available such as adjustable clearance. With an adjustable clearance anvil, converters will compensate for liner variance, or change to a different liner without removing the die, or just utilize inventory tools made previously for a different liner thickness, notes Laakko.

According to Andre Gysbers, marketing director at Wink, a flawless condition of all components in the diecutting station, including cylinders, is crucial for successful diecutting. “To achieve optimum diecutting results, converters need high-quality magnetic cylinders,” he says. “Our magnetic cylinders are the perfect complement to our SuperCut dies. They come with extra-strong adhesion, stainless steel and minimum tolerances. Moreover, the bearer rings can be dismantled and reworked separately, making them very cost-effective.”

Flexible die technology will continue to evolve, too. In the future, converters can expect to see thinner film substrates and liners and faster turnaround times, especially as customers continue to look for increased performance and decreased downtime.

In fact, RotoMetrics can turn around an order on the same day as purchase. “With fast turnaround times, lower investment costs for tooling, freight and storage, the flexible die is the perfect tool for this exploding market segment,” says Laakko. “RotoMetrics consistently ships dies on a 24-hour schedule. Flexible dies within common specifications can be ordered and shipped the same day.”

Ideal for digital

Short runs are the hallmark of digital printing. The ability to offer flexible dies for short turnaround times makes these products ideally suited for the digital printing market.

“The digital label printing market operates on a very short turn time, and therefore requires tooling that can support such time restraints,” says Kocher + Beck’s Morris. “Flexible dies are ideally suited to this, and Kocher + Beck has focused on its internal investments, allowing it to reduce production times and offer short deliver times. With the availability of same day shipping of dies, a digital label printer has the possibility of producing product less than 24 hours after submitting the flexible die order.”

Morris adds that within the digital area of the market, converting speeds will continue to increase with the introduction of newer high speed equipment.

Sinkotech notes that flexible dies and digital printing follow a similar model: Flexible dies are economical and easy to switch from one job to another just like digital printing jobs.

While Wink has seen an increased trend toward laser diecutting for digital jobs, many customers still opt for conventional diecutting because of the wide range of material choices and investments costs.

“We see a strong trend toward short-run digital printing, and overall this affects our business positively, as every different job needs its own unique cutting tool,” says Wink’s Gysbers. “The majority of digital labels comes with rather simple shapes, which enables us to produce and ship the required dies very quickly and cost-effectively.”

New products

With the demand for flexible dies rising, industry suppliers have developed a host of new products to further simplify the diecutting process.

Kocher + Beck, whose core products are manufactured and shipped out of Lenexa, KS, USA, offers a comprehensive range of flexible dies. The company’s expansive portfolio is designed to meet the needs of customers in all market segments. Kocher + Beck’s Universal die is ideal for short-to-medium run lengths and converts materials ranging from PP and PE to PET and card stocks.

For longer run lengths, the company’s 3L (Laser Long Life) is an appropriate choice, incorporating the use of a laser to harden the tip of the cutting blade. This allows the die to remain flexible while increasing the durability of the cutting line. According to Morris, additional coatings and treatments are also available, such as the GlueX coating to prevent adhesive build up, or its Chrome coating, which increases die life when converting thermal transfer materials and aggressive inks.

“On our flexible dies, we have invested significantly in our production processes and equipment to allow us to produce an extremely high-quality tight tolerance die as standard while also focusing on reducing the production time required to meet the needs of our customers,” says Morris. “We were also the first to bring the Gapmaster adjustable anvil product to the market, giving converters an extremely fine level of control range over their diecutting, something that is extremely important when cutting down to the thin PET liners.”

Kocher + Beck produces flexible dies, magnetic cylinders, anvil cylinders, hot stamps and rotary screen material, as well as end rings out of its Lenexa, KS facility. With additional products offered out if its’ headquarters in Germany to meet customers’ needs.

RotoMetrics provides a complete line of flexible dies for converting applications, ranging from simple papers to challenging thin films and even abrasive materials. The company’s completely integrated solutions, which include dies, magnetic cylinders, anvils and more, are important, as all variables that impact the converting process must be considered in a print job.

By acquiring Electro Optic, RotoMetrics furthered its portfolio of flexible die technologies. RotoMetrics now offers proprietary manufacturing processes with Electro Optic’s exclusive technologies, particularly as they relate to automating processes, coating processes and blade technologies, combining the best of both organizations. “This combination resulted in unprecedented industry improvements in flexible die consistency, blade levelness, durability and longevity,” says RotoMetrics’ Laakko. “Our flexible dies equip converters with elite technology to do things they just couldn’t do before. We are converting thinner films faster and more abrasive materials longer than ever.”

RotoMetrics’ development of exclusive coatings and treatments has positively impacted press performance. “For over 60 years now, RotoMetrics has built relationships with our customers, listening to their needs and developing innovative solutions for their converting challenges,” adds Laakko.

Sinkotech prides itself on excellent and dynamic customer service, product value and fast solutions for any cutting problem. “Our target is to be the best solution partnership,” the company says.

Sinkotech has utilized several techniques to improve the performance of its flexible dies. “We do not use any heavy metals, such as chrome, to make our dies look shiny or last longer because such coatings create rounded tips, causing failure when cutting film against thin liners,” the company says. “For this reason, our flexible dies’ appearance is not shiny, but maintains sharp tips, and our long-life dies are also achieved without such coatings.”

Wilson’s flexible cutting dies combine the benefits of performance plus cost savings – all in one product, the company says. Wilson’s dies start from hardened spring steel and utilize computer-to-plate technology, chemical etching and machine sharpening. “We offer a variety of dies that are application specific,” explains Wilson’s Fouts. “This includes Flex Pro, Flex Pro-film, Flex Film Extreme, Flex Extreme and Flex Anti-adhesive.” Wilson holds numerous patents, including its proprietary premium, fully hardened, machine-sharpened dies. “In August of 2018, we moved into a new state-of-the-art facility, fully-equipped with the latest equipment and technology for Lean, high-quality manufacturing,” adds Fouts.

Wink offers a comprehensive range of premium quality flexible dies. Wink’s SuperCut dies cover all kinds of label and narrow web applications, and each SuperCut die is adapted to customers’ requirements using the latest CNC technology. Special surface treatments significantly increase the service life of the tools, notes Wink’s Gysbers. These finishings include laser hardening, MCR MicroChrome coating for extreme long runs and abrasive materials, as well as four different non-stick coatings that minimize the adhesion of adhesive and paint residues.

“Our range of flexible dies is accompanied by all types of rotary cylinders, including solid dies, magnetic, printing, sheeting and anvil cylinders, the SmartGap adjustable anvil system, diecutting stations and pressure gauges,” says Gysbers. “All our dies are cut by laser, which not only guarantees perfectly parallel edges, but also minimizes the risk of injury. And our range of blade geometries is unique and offers the best cutting results for any application.”

Aztec Label, a narrow web tradehouse located in the UK, is installing AccuStrike anvils on each of its three Nilpeter FB presses at its production facility in Kidderminster as part of an ongoing program of investment in production efficiency. The new equipment is RotoMetrics’ answer to die wear and the problems posed by some of today’s tricky filmic substrates.

Founded in 1993 by Colin Le Gresley and now employing 25 staff, the company offers label printing in up to 10 colors on its dual water-based/UV press lines. A RotoMetrics user from day one, Aztec buys all its flexible and solid dies from the Aldridge-based supplier, and according to Le Gresley, a number of bespoke parts too. “The depth of knowledge at RotoMetrics is second to none – they even rebuilt a gear-train on a print cylinder for us a few years back, and we now send all of our operators on their training courses, so they understand the science behind the technology and learn good tool management skills,” he explains.

The new AccuStrike anvils will offer a high degree of die adjustability to the press operators. A simple drop-in installation, the new anvils require no modification to the existing die tool inventory, but by allowing movement of the bearers, either independently or together, the accuracy of die strike across the full web can be maintained. This prolongs die life and reduces cycle times with the resulting lower replacement cost and is all part of Colin Le Gresley’s drive to improve the operational environment and drive up productivity.

“I saw first hand how AccuStrike improved the performance of flexible dies on the press, so now we need to educate our operators to a new way of thinking and setting the tool. I’m a firm believer in investing for efficiency and improving the working environment – it’s sound financial planning for the future and saves the extra cost of trying to play catch-up later,” he adds. Aztec Label will produce sales of around £3m this year, with a target of £4m to take the company to the next stage. Having purchased and converted a 15,000 square foot facility back in 2015 that now offers a state-of-the-art production and admin setup, there is little doubt that Colin Le Gresley has a clear vision for the company’s future. This includes a policy of positive recruitment from the younger age group who will soon need to take on the roles of staff that has been with Aztec since the beginning.

“We offer a quality service to our customers and need the best equipment to do so – but even that’s no use without first class support and service from our suppliers to back it up. RotoMetrics ticks both boxes for us, and the new AccuStrike technology will make a significant difference our diecutting efficiency,” he concludes.