Greg Hrinya, Associate Editor09.06.19

Some of the world’s most popular brands oftentimes will not be able to produce a striking label without a cutting-edge flexo plate. For long runs of many well-known products on the shelf, from cosmetics to personal care to food and drink, flexo plates play an enormous role in making the label a reality.

According to Joseph Sanchez, Northeast regional manager at Dantex, “Your plates are the lifeblood of your business.”

The right flexo plate – both in terms of design and material – is key for high-quality labels. “Having the right plate that has been developed specifically for a certain type of ink or substrate allows the highest quality printing,” says Ellen Farrell, corporate account and territory manager at DuPont. “DuPont carries numerous sizes, durometers, thicknesses, surface textures, and formulations of plates for coatings and UV inks. The result is perfectly matched plates for the job.”

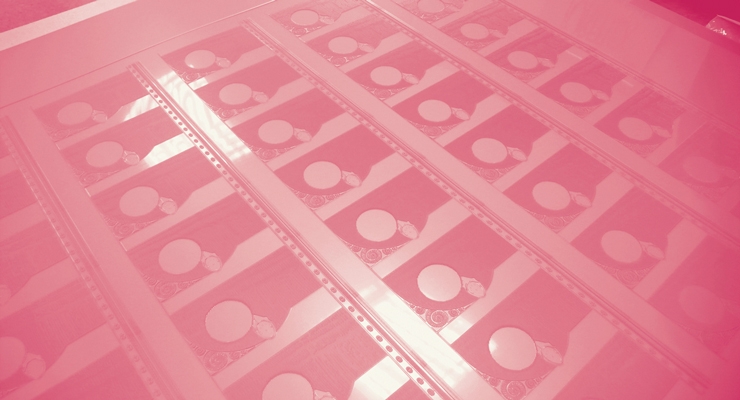

DuPont’s plates are comprised of layers of various photopolymers. Label printers then image these plates with a CDI (Cyrel Digital Imager), for example, subsequently processing with either a solvent or thermal-based system. Thermal systems, however, are growing in popularity versus their solvent-based counterparts. “We see thermal systems becoming more popular due to the speed at which a plate can be made, as no drying of the plate is needed,” notes Farrell. “There are also smaller equipment footprints, lower equipment investment, and reduced environmental concerns surrounding VOCs and sustainability. We see our customers going to thinner plates in some segments, as well as transitioning from solvent to thermal systems.”

Plates have come a long way in the last 25 years. Digital photopolymer plates were the natural evolution to analog photopolymer plates. This technological advancement brought about better imaging and print capabilities, as well as consistency. On the down side, the digital platemaking process produced very fine, bullet-shaped highlight dots, which were more sensitive to impression and wear.

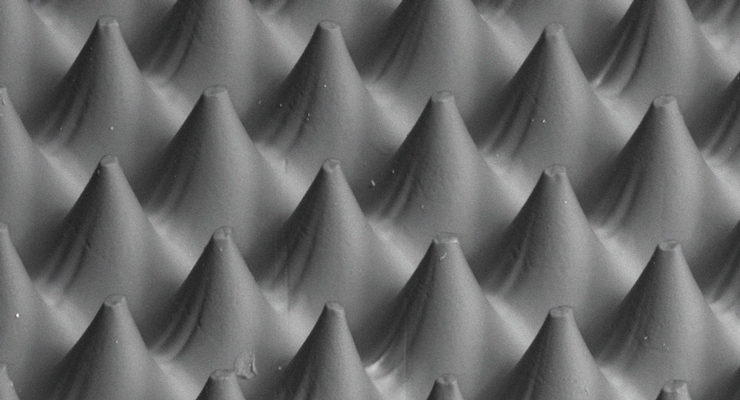

Flat-top dots, however, have changed the printing game. According to MacDermid, the next wave of plate technology occurred in the mid-2010’s. “The LUX lamination process added flat-top dots to a standard digital plate, explains Ryan Vest, director of innovation at MacDermid Graphics Solutions. “The unique LUX dot shape reduced the effects of impression on dot gain, resulting in longer runs, more reliable color, and fewer press adjustment stops. Newer plate offerings, such as our LUX ITP 60, have extremely high-resolution capabilities that allow for the ability to work with new screening packages being offered in the market today.”

The latest technologies not only enhance image production, but they reduce the hard edge/fade to zero effects, and allow for improvements in age-old defects such as dot bridging and quartertone “rivering” effects, adds Vest. The net result, when combined with surface screening or capped plate technologies to enhance solid ink laydown, is images that stand out with color saturation and photorealistic detail. Today’s plate technology surges beyond the capabilities of the earlier generations.

“The advancements have been clearly directed toward the ‘offset-style’ platemaking goal of one-touch in, one-touch out,” says Vest. “In addition, modern platemaking systems are gearing toward remote diagnostic tools and system-to-system communication–allowing a platemaking facility to see platemaking as part of the whole print and package development process, rather than just a separate, unique step.”

Of course, as with any other printing technology, time is money. Printers must balance time and cost with respect to their print runs. Flint Group has gone to great lengths to see that its products adhere to both, especially when it comes to plate exposure.

“UV LEDs are still very expensive, so exposing plates with UV LEDs is a balance of cost and time,” says PJ Fronczkiewicz, North American product manager, printing plates at Flint Group Flexographic. “Plates, such as Flint Group’s nyloflex NEF, have been developed to react more quickly to the exposure process and reduce the overall time considerably.”

Flint Group has solutions for solvent, thermal and water-wash platemaking. In the company’s nyloflex flexo plate portfolio, it offers solvent-washable plates and equipment, as well as thermal plates and platemaking equipment with Flint Group’s nyloflex Xpress Thermal Processing System. In Flint Group’s nyloprint letterpress plate portfolio, the company provides water-wash plates and equipment for rotary letterpress, dry offset printing of tubes, cups and cans, security printing, pad printing, and other processes such as embossing and foil stamping.

A number of factors will dictate the platemaking choice, as one size does not fit all. “Often, in-house platemakers will have thermal to be able to quickly replace the plate if it fails on press, versus the higher resolution and detail achieved from the solvent based plates,” says John Anderson, director of Advanced Print Applications at Miraclon. “The thermal process heats and rips away unwanted photopolymer using pressure and non-woven wicking materials opposed to a dissolving action of the solvents, allowing more detailed features to be achieved.”

Anderson adds that the solvent-processed Kodak Flexcel NX plates tend to fail significantly less on-press, diminishing the impact of the speed of platemaking for a replacement. “Over the years, the core Flexcel NX System technology has been refined and advanced so that, time and time again, Flexcel NX plates offered customers a real differentiator to set themselves apart from their competitors. Kodak Flexcel NX Systems are available in four different configurations, and are suitable for virtually every flexo application.”

According to Fronczkiewicz, plate format size and thickness, turnaround time, and sustainability goals are all important factors to keep in mind.

Flint Group states that the nyloflex Xpress Thermal Processing System uses up to 94% less electricity than solvent platemaking, the developer fabric uses up to 33% fewer raw materials than competitive thermal systems, and the low processing temperatures generate virtually no VOCs. All the while, there is no water consumed that may create additional treatment or environmental disposal concerns.

The water wash advantage

While flexo plates can be processed with solvents or thermal, water wash technology is also a viable option. Water wash plates are processed at relatively low processing temperatures and do not swell. This provides excellent dimensional stability, resulting in highly accurate registration and improved ink transfer characteristics, allowing plates to run cleaner with less ink build-up.

For this market, Fujifilm offers Flenex FW Series plates and the C-Touch Processor. In addition to environmental friendliness, the product range features increased ink transfer, high-quality flat-top dots, and reduced platemaking time.

“Flenex FW series water wash plates provide one of the fastest, high quality, and cost effective flexo platemaking processes in the industry today,” says Shane Govert, product manager at Fujifilm. “The FW series plates reduces platemaking processing times to nearly 30 minutes, maximizing your output while maintaining high-quality through its naturally occurring flat-top dot technology.”

Washout of the Flenex plates is accomplished using a C-Touch All-In-One processor with mild detergent and warm water reducing the environmental impact. Govert adds that converters can now maintain a stable environment with a consistent flat-top dot reproduction of 1% at 200 lpi, delivering more reliable and repeatable results in less time than ever before.

According to Dantex, it has perfected what was historically a “messy” process. In a response to environmental demands, Dantex has developed water wash plates that feature the characteristics of a solvent plate.

“It’s not the gooey water wash plate of the past,” says Dantex’s Sanchez. “The plate washes out really cleanly, the print is incredible and it’s very durable. It’s really a fantastic plate.”

Dantex has also alleviated many of the concerns surrounding ink transfer. “What’s nice about water wash plates is we have an inherent flat-top dot just in the process of making the plate,” explains Sanchez. “It’s one of those attributes that is part of the plate, so we actually have about a 2.5-3% bump curve. What that means for the end user is that we have more ink transfer at a smaller dot.

“The other benefit to Dantex plates is we don’t need to have any of these newer screening technologies, such as plate cell patterning, to transfer more ink,” he adds. “We don’t need to have hybrid screening or anything else. We have a really nice gradation.”

Dantex plates are environmentally friendly, as the waste water can passably go through the sewer. The company produces its own surfactant that omits popular dyes and drying agents, which can be damaging to plates in long-term storage. “Our surfactant keeps all the polymers in suspension, so that when we are washing out plates we don’t have a buildup of any kind of sludge. Then again, everything is environmentally friendly so it can safely run through the sewer system.”

Dantex offers the Aquaflex Optima line of flexo plates, which requires little or no bump curve since it has a minimized oxygen inhibition effect. “This allows the plate to hold a very fine detail without special imaging or exposure conditions,” says Michelle Garza, VP of operations at Dantex. “With our Dantex Aquaflex plate processors, the ease of cleaning, durability on-press, and excellent print quality, this plate can hold its own against solvent and thermal plates.”

Dantex produces plates within 30 minutes, and they’re press ready without any swell. When making a solvent plate, Sanchez notes, companies might expedite the drying process with high-energy ovens. However, this process can dry out the plates, making them more brittle. “Thermal plates never have to be dried and they’re ready in 30 minutes,” he says. “They have a very consistent print surface, but so do we. The benefits of us versus thermal is that we’re just as quick–if not a little quicker–but we’re a lot more economically priced. Thermal is a premium plate and can be expensive, and their ink transfers are not as good as ours.

“Our plates are very durable,” Sanchez concludes. “They’re the most durable plates that we’ve ever released. They last just as long as a solvent plate, and with our surfactant and what we do with the plates, the plates last longer in storage.”

Flat-top dots

Flat-top dots have facilitated higher quality in label printing, and this is a trend that has emerged in recent years. According to Troy Gray, territory sales manager at Dantex, flat-top dot plates are more stable on-press and less prone to color shift as pressures change throughout the pressrun. Plus, the plates are easier to set impression.

“Flat-top dots are essential for high quality, high performing flexo plates,” explains Miraclon’s Anderson. “In 2008, Kodak pioneered the digital flat-top dot in flexo platemaking with the Flexcel NX System, which offered a solution to some of the limitations of digital LAMS technology. Kodak’s patented Thermal Imaging Layer and proprietary Flexcel NX platemaking process remains the only solution on the market that can deliver a true 1:1 reproduction of the digital file to the press-ready plate.”

Prior to the flat-top dot, round-top dot plates were the mainstream choice. However, the effect of oxygen inhibition requiresextra steps in the platemaking process.

“Now, with many inherently flat-top dot plates available – which overcome oxygen inhibition via specialized plate chemistry – there is a return to simplicity in the process,” explains Flint Group’s Fronczkiewicz. “No longer are these additional steps, consumables or investments required to create flat-top dots. In effect, inherently flat-top dot plates have brought us back to the simplicity of the platemaking process where we were 10 years ago. And with emerging advancements in platemaking automation, we are poised and destined to continue down the path of eliminating steps and touch points in the process.”

“One of the ways flexographic plates have evolved in recent years has been the development of the built-in flat-top dot,” notes Jeff Hansen, regional marketing manager, Americas – DuPont Advanced Printing. “DuPont’s system is called Cyrel EASY because it makes the process of making a flat-top dot ‘easy.’ When EASY is combined with FAST, our thermal processing system, it provides fast, easy and award-winning quality.”

MacDermid’s Vest emphasizes that flat-top dots offer increased impression latitude, print consistency and faster press start-ups. “With MacDermid’s LUX ITP technology, you get near 1:1 imaging with an optimized dot structure for better wear characteristics,” he says. “With the bump curve greatly minimized, that means you have now opened up your tonal range to print a wider range. This can give you cleaner vignettes, better highlight definition, or allow you to hit those ‘impossible’ spot colors with process color inks.”

According to DuPont’s Hansen, making a flat-top dot has traditionally been done with a workflow-based solution such as equipment involving oxygen depletion via a nitrogen bath or cumbersome lamination processes. DuPont Cyrel EASY plates have the flat top dot built in, which simplifies the process as it requires less time to make a plate. In addition to flat-top dots, the micro-textured surfaces of DuPont Cyrel plates allow for better ink laydown without software screening.

Prodded by a customer to look into flat-top dots, Prairie State Group (PSG) has invested in an Esko CDI Spark 4835 flexo plate imager with Full HD and Pixel+, along with a MacDermid LUX In-the-Plate system. Not only has gravure-like quality exceeded expectations, but the system has become easier and faster to use, both in the plate department and on-press.

PSG’s flexo plate imager was not capable of creating flat-top dots, fades in highlights and shadows to meet market demands. It wasn’t until a client requested flat-top dots, though, that the company reached a tipping point. “We wanted to wait until we knew where the technology was going,” says Dan Doherty, executive VP of operations and principle.

PSG evaluated imaging systems from its former supplier and Esko. “The other system, with an extra, second film layer processing step, required more equipment and labor. No one in our plate department wanted to add another step. The Esko system was much simpler to operate. With a full Esko front end, we knew that an Esko partnership would mean excellent support and training,” adds Doherty.

In November 2017, PSG, working with Esko and All Printing Resources (APR), decided to invest in an Esko CDI Spark 4835 flexo plate imager with HD Flexo and Pixel+, together with a MacDermid LUX In-the-Plate system. Pixel+ was developed particularly for Esko flexographic plate supplier partners. It provides additional flat-top dot support for plate technologies.

All Printing Resources (APR) and Esko provided the installation and training, which went smoothly. “They were here 2.5 days and helped us determine our standard dots and the configurations – and still returned to check up on us. Cayleigh Anderson, responsible for business development at APR, regularly supports us,” says Doherty.

“The greatest benefit is the ease of setting up files. Our minimums are rarely a concern anymore,” explains Charles Strezo, lead prepress technician. “Our prepress department is less concerned about challenging jobs, and we are willing to raise the bar without all of the preparation. We just let the screens fall where they are, which, in turn, accelerates our output.”

“HD Flexo and Pixel+ did what Esko promised it would do. We love the solids—on both labels and films. We have also eliminated problems with trailing edges,” comments Randy Crutchfield, pressroom manager. “Esko mentioned that we would have wider latitude on the press. It’s a noticeable difference. We are able to lay down a good coating of ink – a nicer, softer impression touch on-press. Make-ready time and waste have decreased, and we now have more uptime. While there are many variables, we believe that our new plates are helping.”

“With our new imaging system, line colors in the type and backgrounds look a lot better than before,” explains Tom Peters, second shift supervisor. “Also, at the end of a roll, the process looks exactly the same as when we started. We don’t find any dot gain or hue change, and dots stay cleaner. We do not get as much swell on plates because there is not as much pressure on them. Our press operators are much happier.”

“The first job PSG printed with the new CDI was perhaps the most challenging one they ever ran. It contained an ombre effect of four-color build fades from left to right and from the top to the bottom,” recalls Anderson. “Without the new CDI, we would not have been able to produce the job successfully. There would have been lots of banding, steps, and hard edges.”

“New technology is a beautiful thing,” adds PSG president Graham Redding. “We can provide gravure-like quality at flexo costs. That gets people’s attention.”

“When press operators with 15-25 years of experience come and say they love the plates, you know you have spent your money in the right place,” concludes Doherty.

According to Joseph Sanchez, Northeast regional manager at Dantex, “Your plates are the lifeblood of your business.”

The right flexo plate – both in terms of design and material – is key for high-quality labels. “Having the right plate that has been developed specifically for a certain type of ink or substrate allows the highest quality printing,” says Ellen Farrell, corporate account and territory manager at DuPont. “DuPont carries numerous sizes, durometers, thicknesses, surface textures, and formulations of plates for coatings and UV inks. The result is perfectly matched plates for the job.”

DuPont’s plates are comprised of layers of various photopolymers. Label printers then image these plates with a CDI (Cyrel Digital Imager), for example, subsequently processing with either a solvent or thermal-based system. Thermal systems, however, are growing in popularity versus their solvent-based counterparts. “We see thermal systems becoming more popular due to the speed at which a plate can be made, as no drying of the plate is needed,” notes Farrell. “There are also smaller equipment footprints, lower equipment investment, and reduced environmental concerns surrounding VOCs and sustainability. We see our customers going to thinner plates in some segments, as well as transitioning from solvent to thermal systems.”

Plates have come a long way in the last 25 years. Digital photopolymer plates were the natural evolution to analog photopolymer plates. This technological advancement brought about better imaging and print capabilities, as well as consistency. On the down side, the digital platemaking process produced very fine, bullet-shaped highlight dots, which were more sensitive to impression and wear.

Flat-top dots, however, have changed the printing game. According to MacDermid, the next wave of plate technology occurred in the mid-2010’s. “The LUX lamination process added flat-top dots to a standard digital plate, explains Ryan Vest, director of innovation at MacDermid Graphics Solutions. “The unique LUX dot shape reduced the effects of impression on dot gain, resulting in longer runs, more reliable color, and fewer press adjustment stops. Newer plate offerings, such as our LUX ITP 60, have extremely high-resolution capabilities that allow for the ability to work with new screening packages being offered in the market today.”

The latest technologies not only enhance image production, but they reduce the hard edge/fade to zero effects, and allow for improvements in age-old defects such as dot bridging and quartertone “rivering” effects, adds Vest. The net result, when combined with surface screening or capped plate technologies to enhance solid ink laydown, is images that stand out with color saturation and photorealistic detail. Today’s plate technology surges beyond the capabilities of the earlier generations.

“The advancements have been clearly directed toward the ‘offset-style’ platemaking goal of one-touch in, one-touch out,” says Vest. “In addition, modern platemaking systems are gearing toward remote diagnostic tools and system-to-system communication–allowing a platemaking facility to see platemaking as part of the whole print and package development process, rather than just a separate, unique step.”

Of course, as with any other printing technology, time is money. Printers must balance time and cost with respect to their print runs. Flint Group has gone to great lengths to see that its products adhere to both, especially when it comes to plate exposure.

“UV LEDs are still very expensive, so exposing plates with UV LEDs is a balance of cost and time,” says PJ Fronczkiewicz, North American product manager, printing plates at Flint Group Flexographic. “Plates, such as Flint Group’s nyloflex NEF, have been developed to react more quickly to the exposure process and reduce the overall time considerably.”

Flint Group has solutions for solvent, thermal and water-wash platemaking. In the company’s nyloflex flexo plate portfolio, it offers solvent-washable plates and equipment, as well as thermal plates and platemaking equipment with Flint Group’s nyloflex Xpress Thermal Processing System. In Flint Group’s nyloprint letterpress plate portfolio, the company provides water-wash plates and equipment for rotary letterpress, dry offset printing of tubes, cups and cans, security printing, pad printing, and other processes such as embossing and foil stamping.

A number of factors will dictate the platemaking choice, as one size does not fit all. “Often, in-house platemakers will have thermal to be able to quickly replace the plate if it fails on press, versus the higher resolution and detail achieved from the solvent based plates,” says John Anderson, director of Advanced Print Applications at Miraclon. “The thermal process heats and rips away unwanted photopolymer using pressure and non-woven wicking materials opposed to a dissolving action of the solvents, allowing more detailed features to be achieved.”

Anderson adds that the solvent-processed Kodak Flexcel NX plates tend to fail significantly less on-press, diminishing the impact of the speed of platemaking for a replacement. “Over the years, the core Flexcel NX System technology has been refined and advanced so that, time and time again, Flexcel NX plates offered customers a real differentiator to set themselves apart from their competitors. Kodak Flexcel NX Systems are available in four different configurations, and are suitable for virtually every flexo application.”

According to Fronczkiewicz, plate format size and thickness, turnaround time, and sustainability goals are all important factors to keep in mind.

Flint Group states that the nyloflex Xpress Thermal Processing System uses up to 94% less electricity than solvent platemaking, the developer fabric uses up to 33% fewer raw materials than competitive thermal systems, and the low processing temperatures generate virtually no VOCs. All the while, there is no water consumed that may create additional treatment or environmental disposal concerns.

The water wash advantage

While flexo plates can be processed with solvents or thermal, water wash technology is also a viable option. Water wash plates are processed at relatively low processing temperatures and do not swell. This provides excellent dimensional stability, resulting in highly accurate registration and improved ink transfer characteristics, allowing plates to run cleaner with less ink build-up.

For this market, Fujifilm offers Flenex FW Series plates and the C-Touch Processor. In addition to environmental friendliness, the product range features increased ink transfer, high-quality flat-top dots, and reduced platemaking time.

“Flenex FW series water wash plates provide one of the fastest, high quality, and cost effective flexo platemaking processes in the industry today,” says Shane Govert, product manager at Fujifilm. “The FW series plates reduces platemaking processing times to nearly 30 minutes, maximizing your output while maintaining high-quality through its naturally occurring flat-top dot technology.”

Washout of the Flenex plates is accomplished using a C-Touch All-In-One processor with mild detergent and warm water reducing the environmental impact. Govert adds that converters can now maintain a stable environment with a consistent flat-top dot reproduction of 1% at 200 lpi, delivering more reliable and repeatable results in less time than ever before.

According to Dantex, it has perfected what was historically a “messy” process. In a response to environmental demands, Dantex has developed water wash plates that feature the characteristics of a solvent plate.

“It’s not the gooey water wash plate of the past,” says Dantex’s Sanchez. “The plate washes out really cleanly, the print is incredible and it’s very durable. It’s really a fantastic plate.”

Dantex has also alleviated many of the concerns surrounding ink transfer. “What’s nice about water wash plates is we have an inherent flat-top dot just in the process of making the plate,” explains Sanchez. “It’s one of those attributes that is part of the plate, so we actually have about a 2.5-3% bump curve. What that means for the end user is that we have more ink transfer at a smaller dot.

“The other benefit to Dantex plates is we don’t need to have any of these newer screening technologies, such as plate cell patterning, to transfer more ink,” he adds. “We don’t need to have hybrid screening or anything else. We have a really nice gradation.”

Dantex plates are environmentally friendly, as the waste water can passably go through the sewer. The company produces its own surfactant that omits popular dyes and drying agents, which can be damaging to plates in long-term storage. “Our surfactant keeps all the polymers in suspension, so that when we are washing out plates we don’t have a buildup of any kind of sludge. Then again, everything is environmentally friendly so it can safely run through the sewer system.”

Dantex offers the Aquaflex Optima line of flexo plates, which requires little or no bump curve since it has a minimized oxygen inhibition effect. “This allows the plate to hold a very fine detail without special imaging or exposure conditions,” says Michelle Garza, VP of operations at Dantex. “With our Dantex Aquaflex plate processors, the ease of cleaning, durability on-press, and excellent print quality, this plate can hold its own against solvent and thermal plates.”

Dantex produces plates within 30 minutes, and they’re press ready without any swell. When making a solvent plate, Sanchez notes, companies might expedite the drying process with high-energy ovens. However, this process can dry out the plates, making them more brittle. “Thermal plates never have to be dried and they’re ready in 30 minutes,” he says. “They have a very consistent print surface, but so do we. The benefits of us versus thermal is that we’re just as quick–if not a little quicker–but we’re a lot more economically priced. Thermal is a premium plate and can be expensive, and their ink transfers are not as good as ours.

“Our plates are very durable,” Sanchez concludes. “They’re the most durable plates that we’ve ever released. They last just as long as a solvent plate, and with our surfactant and what we do with the plates, the plates last longer in storage.”

Flat-top dots

Flat-top dots have facilitated higher quality in label printing, and this is a trend that has emerged in recent years. According to Troy Gray, territory sales manager at Dantex, flat-top dot plates are more stable on-press and less prone to color shift as pressures change throughout the pressrun. Plus, the plates are easier to set impression.

“Flat-top dots are essential for high quality, high performing flexo plates,” explains Miraclon’s Anderson. “In 2008, Kodak pioneered the digital flat-top dot in flexo platemaking with the Flexcel NX System, which offered a solution to some of the limitations of digital LAMS technology. Kodak’s patented Thermal Imaging Layer and proprietary Flexcel NX platemaking process remains the only solution on the market that can deliver a true 1:1 reproduction of the digital file to the press-ready plate.”

Prior to the flat-top dot, round-top dot plates were the mainstream choice. However, the effect of oxygen inhibition requiresextra steps in the platemaking process.

“Now, with many inherently flat-top dot plates available – which overcome oxygen inhibition via specialized plate chemistry – there is a return to simplicity in the process,” explains Flint Group’s Fronczkiewicz. “No longer are these additional steps, consumables or investments required to create flat-top dots. In effect, inherently flat-top dot plates have brought us back to the simplicity of the platemaking process where we were 10 years ago. And with emerging advancements in platemaking automation, we are poised and destined to continue down the path of eliminating steps and touch points in the process.”

“One of the ways flexographic plates have evolved in recent years has been the development of the built-in flat-top dot,” notes Jeff Hansen, regional marketing manager, Americas – DuPont Advanced Printing. “DuPont’s system is called Cyrel EASY because it makes the process of making a flat-top dot ‘easy.’ When EASY is combined with FAST, our thermal processing system, it provides fast, easy and award-winning quality.”

MacDermid’s Vest emphasizes that flat-top dots offer increased impression latitude, print consistency and faster press start-ups. “With MacDermid’s LUX ITP technology, you get near 1:1 imaging with an optimized dot structure for better wear characteristics,” he says. “With the bump curve greatly minimized, that means you have now opened up your tonal range to print a wider range. This can give you cleaner vignettes, better highlight definition, or allow you to hit those ‘impossible’ spot colors with process color inks.”

According to DuPont’s Hansen, making a flat-top dot has traditionally been done with a workflow-based solution such as equipment involving oxygen depletion via a nitrogen bath or cumbersome lamination processes. DuPont Cyrel EASY plates have the flat top dot built in, which simplifies the process as it requires less time to make a plate. In addition to flat-top dots, the micro-textured surfaces of DuPont Cyrel plates allow for better ink laydown without software screening.

Prodded by a customer to look into flat-top dots, Prairie State Group (PSG) has invested in an Esko CDI Spark 4835 flexo plate imager with Full HD and Pixel+, along with a MacDermid LUX In-the-Plate system. Not only has gravure-like quality exceeded expectations, but the system has become easier and faster to use, both in the plate department and on-press.

PSG’s flexo plate imager was not capable of creating flat-top dots, fades in highlights and shadows to meet market demands. It wasn’t until a client requested flat-top dots, though, that the company reached a tipping point. “We wanted to wait until we knew where the technology was going,” says Dan Doherty, executive VP of operations and principle.

PSG evaluated imaging systems from its former supplier and Esko. “The other system, with an extra, second film layer processing step, required more equipment and labor. No one in our plate department wanted to add another step. The Esko system was much simpler to operate. With a full Esko front end, we knew that an Esko partnership would mean excellent support and training,” adds Doherty.

In November 2017, PSG, working with Esko and All Printing Resources (APR), decided to invest in an Esko CDI Spark 4835 flexo plate imager with HD Flexo and Pixel+, together with a MacDermid LUX In-the-Plate system. Pixel+ was developed particularly for Esko flexographic plate supplier partners. It provides additional flat-top dot support for plate technologies.

All Printing Resources (APR) and Esko provided the installation and training, which went smoothly. “They were here 2.5 days and helped us determine our standard dots and the configurations – and still returned to check up on us. Cayleigh Anderson, responsible for business development at APR, regularly supports us,” says Doherty.

“The greatest benefit is the ease of setting up files. Our minimums are rarely a concern anymore,” explains Charles Strezo, lead prepress technician. “Our prepress department is less concerned about challenging jobs, and we are willing to raise the bar without all of the preparation. We just let the screens fall where they are, which, in turn, accelerates our output.”

“HD Flexo and Pixel+ did what Esko promised it would do. We love the solids—on both labels and films. We have also eliminated problems with trailing edges,” comments Randy Crutchfield, pressroom manager. “Esko mentioned that we would have wider latitude on the press. It’s a noticeable difference. We are able to lay down a good coating of ink – a nicer, softer impression touch on-press. Make-ready time and waste have decreased, and we now have more uptime. While there are many variables, we believe that our new plates are helping.”

“With our new imaging system, line colors in the type and backgrounds look a lot better than before,” explains Tom Peters, second shift supervisor. “Also, at the end of a roll, the process looks exactly the same as when we started. We don’t find any dot gain or hue change, and dots stay cleaner. We do not get as much swell on plates because there is not as much pressure on them. Our press operators are much happier.”

“The first job PSG printed with the new CDI was perhaps the most challenging one they ever ran. It contained an ombre effect of four-color build fades from left to right and from the top to the bottom,” recalls Anderson. “Without the new CDI, we would not have been able to produce the job successfully. There would have been lots of banding, steps, and hard edges.”

“New technology is a beautiful thing,” adds PSG president Graham Redding. “We can provide gravure-like quality at flexo costs. That gets people’s attention.”

“When press operators with 15-25 years of experience come and say they love the plates, you know you have spent your money in the right place,” concludes Doherty.