02.15.18

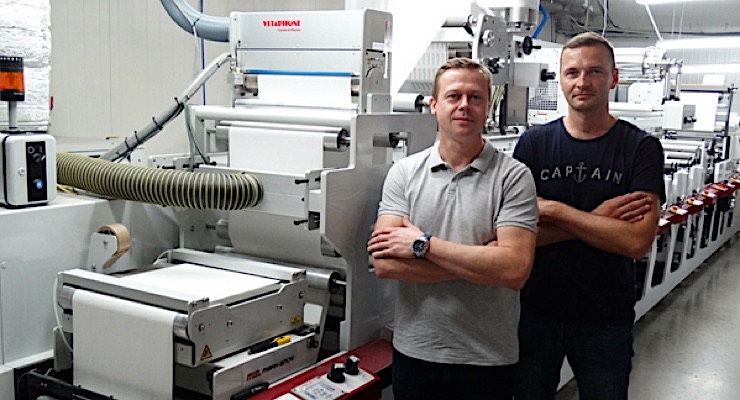

In what the company claims is a significant milestone in its growing market penetration in Europe, Mark Andy has made a sale to Polish label converter Mal-Pol. The new Performance Series P5 press is the first from the American manufacturer to be installed at what has traditionally been a European press user.

“This was a key sale to secure, as it breaks the grip of our competitors and highlights the added benefits that the Performance Series offers converters who are looking to diversify into more profitable market sectors," explains Mark Andy's European managing director Tom Cavalco.

The P5 press in question is a highly specified 8-color flexo line, with a 17" (430mm) web width fitted with dual unwind and rewind, web cleaning, corona treater, and web turn bars, as well as chilled impression rolls. It has a cold foil capability, and for consistent high quality, an automatic register system. At the converting section, it is fitted with a Mark Andy Compact Parallel Web Translator, and there is gap control of the QCDC unit before the waste is rewound on Mark Andy’s new zero gap windup unit.

The new Mark Andy, which joins a variety of existing flexo and digital presses, has been specified to allow Mal-Pol to develop its peel/reseal label business. The Mark Andy Compact Parallel Web Translator unit allows it to produce multi-layer labels, hence the need for dual unwind and rewind, making the press a highly versatile performer, according to Mal-Pol director Maciej Malesa, whose father founded the company in 1993.

“We are fast developing a reputation for peel-off labels and needed a new press that could handle this work more efficiently and cost-effectively than any of our existing technology," says Malesa. "The ease and speed of make-ready on the Mark Andy has opened up all sorts of new job opportunities with shorter and medium runs lengths.”

Traditionally, Mal-Pol has supplied labels to the food, cosmetics, automotive, and industrial markets such as fuel oil. Substrates processed are principally paper-based and laminated foil. It has its own in-house ink kitchen and is fully self-sufficient for prepress. It is in the process of adding a 1,400 square meter extension to its 2,000 square meter facility, after which it intends to add BRC accreditation to its existing ISO status.

Currently, the company staff of 100 operates a triple-shift pattern, and Mal-Pol is looking to grow its business by investing in more efficient technology. “With EU regulations requiring more information to be printed on each label, and the use of multi-language labels, we need to engage in lateral thinking to develop our portfolio – the new Mark Andy is an important part of that plan, because we see it as a platform for business development,” he adds.

“This was a key sale to secure, as it breaks the grip of our competitors and highlights the added benefits that the Performance Series offers converters who are looking to diversify into more profitable market sectors," explains Mark Andy's European managing director Tom Cavalco.

The P5 press in question is a highly specified 8-color flexo line, with a 17" (430mm) web width fitted with dual unwind and rewind, web cleaning, corona treater, and web turn bars, as well as chilled impression rolls. It has a cold foil capability, and for consistent high quality, an automatic register system. At the converting section, it is fitted with a Mark Andy Compact Parallel Web Translator, and there is gap control of the QCDC unit before the waste is rewound on Mark Andy’s new zero gap windup unit.

The new Mark Andy, which joins a variety of existing flexo and digital presses, has been specified to allow Mal-Pol to develop its peel/reseal label business. The Mark Andy Compact Parallel Web Translator unit allows it to produce multi-layer labels, hence the need for dual unwind and rewind, making the press a highly versatile performer, according to Mal-Pol director Maciej Malesa, whose father founded the company in 1993.

“We are fast developing a reputation for peel-off labels and needed a new press that could handle this work more efficiently and cost-effectively than any of our existing technology," says Malesa. "The ease and speed of make-ready on the Mark Andy has opened up all sorts of new job opportunities with shorter and medium runs lengths.”

Traditionally, Mal-Pol has supplied labels to the food, cosmetics, automotive, and industrial markets such as fuel oil. Substrates processed are principally paper-based and laminated foil. It has its own in-house ink kitchen and is fully self-sufficient for prepress. It is in the process of adding a 1,400 square meter extension to its 2,000 square meter facility, after which it intends to add BRC accreditation to its existing ISO status.

Currently, the company staff of 100 operates a triple-shift pattern, and Mal-Pol is looking to grow its business by investing in more efficient technology. “With EU regulations requiring more information to be printed on each label, and the use of multi-language labels, we need to engage in lateral thinking to develop our portfolio – the new Mark Andy is an important part of that plan, because we see it as a platform for business development,” he adds.