04.25.18

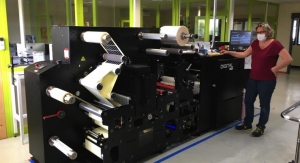

UK-based Reflex Label Plus, formerly Labelsco, which became part of the Reflex Group in 2012, has ordered a top-of-the-range Performance Series P7 from Mark Andy for its plant in Barwell, Leicestershire. The new press, which features the updated P7 platform, brings to 27 the number of Mark Andy presses currently in use at Reflex plants, including the seven P Series presses installed last year at Boston. Significantly this will be the first Mark Andy to be installed at the Barwell site.

The new P7 has direct servo improvements, fully automated job register, and a more ergonomic design to improve ease of operation. Specification of the 20-inch (508mm) 10-color press includes two reverse print stations, delam/relam, and a rail system for foil unwind/rewind, constant tension laminator, and waste rewind. It also has a web translator, single vertical die station, QCDC, and chilled impression drums as part of Mark Andy’s film package.

Speaking for Reflex Label Plus, Operations Manager at Barwell, Raymond Young comments: “Reflex always seeks to be at the forefront of innovation, investing in technology and people for continuous improvement. The Mark Andy P7 was chosen for its ability to redefine workflow productivity through its simple design, efficient waste savings, and extremely fast changeovers.”

Reflex Label Plus manufactures labels and printed laminates for sachets at its sites in Barwell, and Keighley, West Yorkshire. Operations span supply to the personal care and beverage sectors, where the company’s expertise with value-added processes are especially in demand, and to the pharmaceutical sector, for which accuracy and consistent quality is of paramount importance.

Reflex, which was formed in 2002, has always had sustainability at the heart of its operations. Now one of the largest companies of its kind in the UK, and with an international customer portfolio, Reflex serves a broad range of sectors with products that include self-adhesive labels, shrink sleeves, linerless labels, and flexible packaging.

The new P7 has direct servo improvements, fully automated job register, and a more ergonomic design to improve ease of operation. Specification of the 20-inch (508mm) 10-color press includes two reverse print stations, delam/relam, and a rail system for foil unwind/rewind, constant tension laminator, and waste rewind. It also has a web translator, single vertical die station, QCDC, and chilled impression drums as part of Mark Andy’s film package.

Speaking for Reflex Label Plus, Operations Manager at Barwell, Raymond Young comments: “Reflex always seeks to be at the forefront of innovation, investing in technology and people for continuous improvement. The Mark Andy P7 was chosen for its ability to redefine workflow productivity through its simple design, efficient waste savings, and extremely fast changeovers.”

Reflex Label Plus manufactures labels and printed laminates for sachets at its sites in Barwell, and Keighley, West Yorkshire. Operations span supply to the personal care and beverage sectors, where the company’s expertise with value-added processes are especially in demand, and to the pharmaceutical sector, for which accuracy and consistent quality is of paramount importance.

Reflex, which was formed in 2002, has always had sustainability at the heart of its operations. Now one of the largest companies of its kind in the UK, and with an international customer portfolio, Reflex serves a broad range of sectors with products that include self-adhesive labels, shrink sleeves, linerless labels, and flexible packaging.