John Penhallow04.12.17

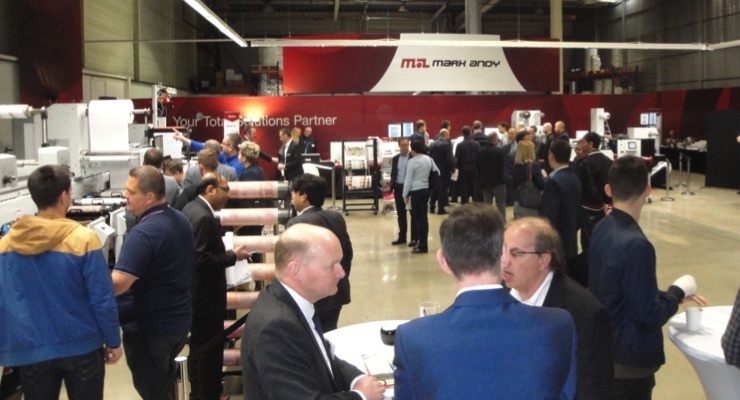

It is two years now since Mark Andy moved its European headquarters to Warsaw, Poland, and for three days in April the manufacturer’s demo center welcomed over 400 customers and potential customers from all parts of Europe, East and West.

Three presses were displayed and demonstrated in Mark Andy’s spacious showroom, on a site close to the Polish capital’s main airport. The first was one of the new generation of Performance Series P7 flexo presses, in a 9-color configuration with a web width of 20”. “This press is modular,” explained Mark Andy's after-sales director Phil Baldwin. “And for the demo we’ve included many of the finishing options available, including an in-line solventless lamination unit.”

The press was demonstrated running at just short of 750 fpm, but the most impressive part of the demo was the speed of a total substrate, die and print change in under ten minutes, including re-register, and ramping back up to full press speed. Able to print substrates from 12 up to 450 microns, this latest version of the P7 can handle not just PS labels but also unsupported film, IML materials, lightweight cartons and many other specialties.

During the P7 demo, curing on all print stations was by UV LED (hot air or mercury UV lamps are also available). “We foresee a big growth in both labels and flexible packaging for the food sector, where low migration is an imperative,” said Baldwin. “For that reason we chose to use LED curing and solventless lamination for today’s demo." Asked how successful the Performance Series had been since its launch in 2012, Baldwin said that in total 600 P Series presses had been sold to date, including just recently two P5s to a customer in Belarus. Another P7 was sold the day after our visit, this time to a Scandinavian converter – who also signed up for a new Mark Andy Digital Series hybrid press!

Mark Andy showed a digital/flexo hybrid press at the Labelexpo shows in 2015 and 2016. “Then, you could admire it – now you can buy it!” exclaimed Raymond Dickinson, Mark Andy's VP Marketing Digital Solutions. Although using a Performance Series chassis, this hybrid press looks – and indeed is – a fully integrated hybrid platform with CMYK+W digital inkjet, two or more flexo stations, rotary diecutting and a full range of converting options.

Visitors to the event saw this press running at around 200 fpm, and a full print and die change (timed by your correspondent) in just over four minutes. The critical part of the press is the part you can’t see: the ProWORX digital front end which links the press to the digital file management used by a converter. This DFE, developed in partnership with Esko, could be the long-awaited breakthrough enabling the analog and digital parts of a hybrid press to be coordinated. In terms of sales, Mark Andy has sold several hybrid presses in North America, and one in Europe, to a start-up converter in Poland. Several more sales were confirmed at the Open House.

The third press demonstrated at the Open Days was the Mark Andy Digital One, an entry-level digital press that uses dry toner technology and has a single flexo station for varnish or cold foil, inline diecutting, and rewinding. This highly compact press (140 x 40 x 60 inches) with its 13-inch web was demonstrated printing at 44 fpm with a 1200 x 1200 dpi resolution.

“These presses are close to a preview of some of the main innovations we will be showing this year at Labelexpo," explained Tom Cavalco, Mark Andy’s recently appointed Managing Director for Europe. Cavalco, though new to his present job, is an old hand with the company, having joined 15 years ago and masterminded the 2015 European Head Office move from Switzerland to Poland. He is confident that the company's digital and hybrid technologies will see off the competition over the coming years. “Some of the recent newcomers to the digital narrow web press business just don’t know the market,” he says. “Whether it be labels or flexible packaging, we know more than a thing or two about the market. The packaged food sector is growing fast in all continents, and particularly in Asia, but brand owners and converters are unsure about the problems of ink migration. That’s where we can and must help them.” He added. Mark Andy works closely with major ink manufacturers like Flint and SunChemical to offer brand owners the security they crave.

The Open Days were also an opportunity to learn more about recent developments in Mark Andy's European activities, as well as its business in other parts of the globe. For example, a new sales and service outpost will soon be set up to cover Germany, Switzerland and Austria, and sales in India, Pakistan and Bangladesh will probably exceed ten presses this year, according to Mr. Suresh, technical sales manager of Flexo Image Graphics, Mark Andy's exclusive agent for the subcontinent.

According to Kevin Gourlay, vice president of the Rotoflex, the future looks bright. Rotoflex now operates as a separate entity (although under the same ownership as Mark Andy), and recently moved production to newer and larger premises in Canada. Demonstrated during the Open Days was the company’s mid-range VSI inspection slitter/rewinder, fitted with the latest web transport and drive controls.

Latest quarterly figures show the Polish economy growing at 7%, which puts it at the very top of the European league. This, together with continued growth of the label and packaging sectors throughout central and Eastern Europe, vindicates Mark Andy's decision to make Warsaw the center of its European sales and service network.

John Penhallow is L&NW's longtime European correspondent and the author of the Narrow Web Europe column, which appears in each issue of the magazine.

Three presses were displayed and demonstrated in Mark Andy’s spacious showroom, on a site close to the Polish capital’s main airport. The first was one of the new generation of Performance Series P7 flexo presses, in a 9-color configuration with a web width of 20”. “This press is modular,” explained Mark Andy's after-sales director Phil Baldwin. “And for the demo we’ve included many of the finishing options available, including an in-line solventless lamination unit.”

The press was demonstrated running at just short of 750 fpm, but the most impressive part of the demo was the speed of a total substrate, die and print change in under ten minutes, including re-register, and ramping back up to full press speed. Able to print substrates from 12 up to 450 microns, this latest version of the P7 can handle not just PS labels but also unsupported film, IML materials, lightweight cartons and many other specialties.

During the P7 demo, curing on all print stations was by UV LED (hot air or mercury UV lamps are also available). “We foresee a big growth in both labels and flexible packaging for the food sector, where low migration is an imperative,” said Baldwin. “For that reason we chose to use LED curing and solventless lamination for today’s demo." Asked how successful the Performance Series had been since its launch in 2012, Baldwin said that in total 600 P Series presses had been sold to date, including just recently two P5s to a customer in Belarus. Another P7 was sold the day after our visit, this time to a Scandinavian converter – who also signed up for a new Mark Andy Digital Series hybrid press!

Mark Andy showed a digital/flexo hybrid press at the Labelexpo shows in 2015 and 2016. “Then, you could admire it – now you can buy it!” exclaimed Raymond Dickinson, Mark Andy's VP Marketing Digital Solutions. Although using a Performance Series chassis, this hybrid press looks – and indeed is – a fully integrated hybrid platform with CMYK+W digital inkjet, two or more flexo stations, rotary diecutting and a full range of converting options.

Visitors to the event saw this press running at around 200 fpm, and a full print and die change (timed by your correspondent) in just over four minutes. The critical part of the press is the part you can’t see: the ProWORX digital front end which links the press to the digital file management used by a converter. This DFE, developed in partnership with Esko, could be the long-awaited breakthrough enabling the analog and digital parts of a hybrid press to be coordinated. In terms of sales, Mark Andy has sold several hybrid presses in North America, and one in Europe, to a start-up converter in Poland. Several more sales were confirmed at the Open House.

The third press demonstrated at the Open Days was the Mark Andy Digital One, an entry-level digital press that uses dry toner technology and has a single flexo station for varnish or cold foil, inline diecutting, and rewinding. This highly compact press (140 x 40 x 60 inches) with its 13-inch web was demonstrated printing at 44 fpm with a 1200 x 1200 dpi resolution.

“These presses are close to a preview of some of the main innovations we will be showing this year at Labelexpo," explained Tom Cavalco, Mark Andy’s recently appointed Managing Director for Europe. Cavalco, though new to his present job, is an old hand with the company, having joined 15 years ago and masterminded the 2015 European Head Office move from Switzerland to Poland. He is confident that the company's digital and hybrid technologies will see off the competition over the coming years. “Some of the recent newcomers to the digital narrow web press business just don’t know the market,” he says. “Whether it be labels or flexible packaging, we know more than a thing or two about the market. The packaged food sector is growing fast in all continents, and particularly in Asia, but brand owners and converters are unsure about the problems of ink migration. That’s where we can and must help them.” He added. Mark Andy works closely with major ink manufacturers like Flint and SunChemical to offer brand owners the security they crave.

The Open Days were also an opportunity to learn more about recent developments in Mark Andy's European activities, as well as its business in other parts of the globe. For example, a new sales and service outpost will soon be set up to cover Germany, Switzerland and Austria, and sales in India, Pakistan and Bangladesh will probably exceed ten presses this year, according to Mr. Suresh, technical sales manager of Flexo Image Graphics, Mark Andy's exclusive agent for the subcontinent.

According to Kevin Gourlay, vice president of the Rotoflex, the future looks bright. Rotoflex now operates as a separate entity (although under the same ownership as Mark Andy), and recently moved production to newer and larger premises in Canada. Demonstrated during the Open Days was the company’s mid-range VSI inspection slitter/rewinder, fitted with the latest web transport and drive controls.

Latest quarterly figures show the Polish economy growing at 7%, which puts it at the very top of the European league. This, together with continued growth of the label and packaging sectors throughout central and Eastern Europe, vindicates Mark Andy's decision to make Warsaw the center of its European sales and service network.

John Penhallow is L&NW's longtime European correspondent and the author of the Narrow Web Europe column, which appears in each issue of the magazine.