Greg Hrinya, Associate Editor09.10.18

Pharmaceutical labels represent an expansive and complex market for converters. This tightly-regulated market must deliver crucial information to the people reading the label. Unlike a wine or beer label, snazzy graphics and eye-popping enhancements are far less relevant in pharmaceuticals.

In pharmaceutical labeling, print quality requirements must meet a certain standard for font size, legibility, accuracy, material qualification, and 100% print inspection. In addition, traceability and durability are key factors of a high-quality label.

“Pharmaceutical labels are not simple in process, material, printing, quality review and inspection and functionality, especially as compared to other types of applications,” says Carl Archambeault, director of R&D at Lux Global Label. “There is typically a destructibility or some type of tamper evidence needed in its function. The adhesives must also be considered for its ultimate bond. Regardless if it needs to have a repositionable window or not, there is still a need for an ultimate and very strong bond to the container.”

“Quality requirements for pharmaceutical labels also differ from those in other applications,” says Oliver Peitzner, product manager at EyeC. “Any errors, like illegible, incorrect or incomplete information on pharmaceutical labels, puts patients’ lives in jeopardy and exposes pharmaceutical companies to a risk of litigation and a damaged reputation. Therefore, quality assurance is so essential for pharmaceutical packaging.”

As Archambeault notes, the label is not just a label. It serves as an intricate functional component of the final product.

Avery Dennison, whose substrates are frequently used for pharmaceutical labels, sees several inherent characteristics of this type of label. Pharmaceutical labels are often tested for toxicology and risk of migration, and the substrates must include protection from change. Not only must they meet government guidelines, these labels will need to perform through sterilization, tight mandrel applications and cold chain environments.

According to Maria Josè Castillo, quality manager for Ritrama., quality drives pharmaceutical labeling. “The quality standards in the industry are very high and demanding and, very often, the labels have to comply with specific requirements, like ISO 15137:2005, which details self-adhesive hanging devices for infusion bottles and injection vials,” she says.

Many different substrates are applicable in this field. “Papers are the most common substrate, but we are beginning to see a shift to more film with the growth of drug products being packaged in vials and syringes,” explains Alison Burns, product manager at Avery Dennison. “Film can provide clarity and better performance for tight mandrel packages. Avery Dennison offers a selection of papers and films that can address a wide variety of applications.”

UPM Raflatac also sees a diverse range of materials being used in this space, with gloss coated papers, BOPP and PET films being commonplace. Paavo Sillanpää, manager, Specials Business Segments, Americas, UPM Raflatac, states that substrate selection depends very much on the application and the market segment. The OTC market mainly uses gloss or semi-gloss papers, while the Rx side features lower gauge papers and films for tight mandrel applications such as test tubes, vials, ampoules and pre-filled syringes. For applications where temperature and chemical resistance and high clarity are required, PET films are widely being used.

“Selecting the right and proven material for the application is very important,” says Sillanpää. “When labeling small diameter containers, it is important to choose a material that has been tested for tight mandrel performance. When labeling plastic containers containing liquid materials, such as eye drops and IV-containers, attention needs to be paid to potential migration risk according to FDA guidelines. In order to secure patient safety, it is important to choose an adhesive that has been tested for low leachable characteristics.”

Digital printing has found relevance in this field, but narrow, mid-web and even wide-web printing presses from flexographic to gravure and rotary-screen and web-offset still drive the market. “There are many times when very unique diecutting is required to enhance the final product,” explains Archambeault. “As security features are used, there is also a strong need to maintain excellent control of the confidentiality and knowledge of how and where such security features are used. This can facilitate special security protocols and controlled holding areas for specific security components and even readers and scanners at times.”

The majority of work is done with flexo printing, and the process might include late stage data encoding with variable information.

The printing press is not the only critical piece of equipment in the pharmaceutical label printing process. Ancillary equipment is required on press and final rewind and includes high-end inspection systems for 100% electronic inspection, special web-handling add-ons and intricate diecutting tools. “Quality assurance, along with all of the testing equipment that goes with it, also has a huge role in the final product’s validation, tracking, traceability and acceptance and ultimate success,” says Archambeault. “If you don’t have an outstanding quality assurance program in place, you will not be very good at meeting your customers’ acceptance of provided labels in this market.”

For Luminer Converting Group, inspection is as critical as any facet of the pharma labeling process. “It is everything,” notes Tom Spina, president and CEO of Luminer Converting Group. “Using automated systems, traceability, cGMP standards, and auditability in one’s facility are completely mandatory and you could not be in this space without quality inspection.”

“This industry is one where information is made to be clear,” adds Burns. “There is a clear hierarchy within the design to help the consumer find the product and then communicate the key benefits and ingredients in an easy to digest manner.”

While legibility and accuracy are undoubtedly key hallmarks of pharmaceutical labeling, there is still an opportunity for designers to lend creativity to packaging – especially as it relates to over the counter (OTC) medicines.

“Despite regulatory challenges, creativity and design definitely continue to play a significant role in OTC pharmaceutical labeling,” explains Martin. “With so many brands now available over the counter, the need for products to attract attention has never been so great. Packaging and labels still play a major marketing role for consumer healthcare brands and strong bold colors and pack embellishments will continue to play a part in enhancing visual shelf appeal to help brands to stand out.”

In fact, Lux Global Label sees the future of pharmaceutical labeling bringing greater creativity to packaging design. “Creativity is alive and well in pharmaceutical, ethical and OTC labeling,” says Archambeault. “The label doesn’t just provide information to the consumer, it also must fit the need to build brand loyalty, marketing for shelf appeal and attraction, to promote the purchasing decision, enhancing the buying decision and even impulse purchasing. The label doesn’t stop at the marketing point either, as a functional label may also be called upon to help with the ever sought after reduction of packaging layers to satisfy the changing push for social responsibility.”

Pharmaceutical Requirements

In addition to the container and substrate, there are numerous governmental regulations that must be adhered to in pharmaceutical labeling. In this segment, regulatory changes have a direct impact on inspection processes and quality requirements. Therefore, print quality is critical in pharmaceutical labeling.

“Pharmaceutical label converters apply 100% quality control and GMP practices in their processes in order to eliminate any potential errors,” says UPM Raflatac’s Sillanpää. “Labelstock suppliers can focus on the high purity of the label material in order to avoid unnecessary stops on inspection lines and provide materials with luminescent additives to help missing label detection on labeling lines.”

As EyeC’s Peitzner observes, even minor defects like the dot on top of an “i” in a small font must be detected. “Pharmaceutical companies have to comply with stringent regulations and norms, such as ISO 9001, GMP, GAMP 5, and must guarantee validation according to the guidelines laid out in US FDA Title 21 CFR Part 11 and comply with local directives,” Peitzner explains. “Thus, they put in place specific processes, like standardized requalification procedures for their inspection systems in order to guarantee consistent inspection results. Or they will implement specific workflows that allow them to fully document and record inspection processes and ensure data integrity and security.”

When it comes to substrates, inks, coatings and varnishes, they all must comply with the latest FDA and EU standards. “Food packaging compliant materials are not only suitable for use in the food industry. As the pharma industry – particularly the OTC sector – has moved away from glass containers to HDPE and LDPE plastics in recent years, companies must consider consumer and patient safety,” says Tony Martin, technical sales manager at Pulse Roll Label Products. “As plastic is not an absolute barrier to the migration of inks and coatings, there has been an increased need for companies to follow Good Manufacturing Practices (GMP) and use compliant packaging materials suitable for non-direct food contact.”

FDA regulations can change often, too, and the adjustment typically requires more information being provided to the consumer. “Some of the requirements through the changing regulations push the envelope, and the printer has to be ever vigilant and proactive in their knowledge of the industry and FDA regulations,” says Lux Global Label’s Archambeault. “While the printer is not the primary stakeholder or final decision point for the packaging, we certainly play our part, as a good supplier, by understanding the changes in regulations and its impact on the labels.”

According to Peitzner, one specific regulation will change next year. A new regulation on pharmaceutical serialization will require printers and pharmaceutical companies to implement unique identifiers for each pharmaceutical product according to the IFA-Coding system. Companies will have until February 9, 2019 to get updated.

“Companies will then have to assign an explicit number to every single product package to enable an easy identification of each product,” Peitzner adds. “With the help of inline inspection systems, such as the EyeC ProofRunner, printers and pharmaceutical companies can check serialization and identify missing or duplicate data during printing and further processing.”

Extended Content

Often times, a patient needs more information than what is available on the space of an average label. Therefore, extended content labels serve a critical purpose in the pharma sector. Lux Global Label defines an extended content label, also known as a leaflet, booklet or insert, as a label that provides the FDA and brand owners required information when the container panel(s) does not have the single level real-estate available to communicate all of the information needed.

“Recent legislation, in terms of information about drugs and medicine, has forced printers to develop booklet labels,” explains Ritrama’s Castillo. “Ritrama has developed products to meet the needs for this type of construction.”

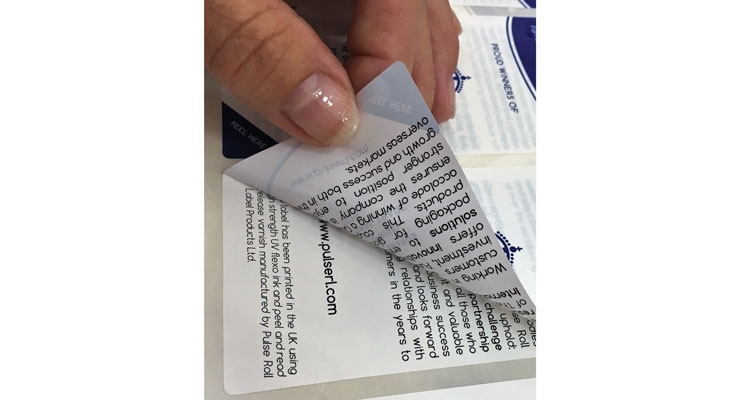

Extended content labels are suitable for use on a wide range of packaging, containers and bottles. Peel and read labels allow additional space on the package for consumer product and safety information and user instructions without sacrificing graphics, visual appeal and impact on shelf.

“These labels, which allow extended content, are often referred to as peel and reveal, multi-layer or piggy-back labels, and prove particularly valuable in the pharmaceutical sector where there is a legal obligation to provide extensive information, including instructions and ingredients in multiple languages,” says Pulse Roll Label’s Martin. “It’s also important to have adhesives that allow the label to be resealed by offering ‘repeatable’ release properties.”

Luminer Converting Group has found its niche with these types of labels. “In our case, the vast majority of our pharma business is in expanded content,” says Spina. “We produce pharma labels from two pages up to 60 pages on a single label, to be applied to a bottle, carton or box. The regulatory and global demands of drug information and languages keep pushing the need for more and more content in a small space.”

These labels often deal with tight government mandates, due to the wealth of information contained within. Global Harmonization mandates have increased the need for expanded content labels in the pharmaceutical space, as well as many other consumer product areas.

EyeC has developed specific technology to handle the inspection requirements of extended content labels. Their inspection can now be performed simply with multi-template inspection. “This function enables a check of the different pages of the extended label against several PDF files in one inspection cycle automatically,” Peitzner states. “The control of distances within, as well as, between labels can now be performed automatically with PDF proofing systems or off-line inspection systems. Equipped with the function ‘Automatic Distance Measurement,’ EyeC systems can check all user-defined distances and notify the operator if any of the measurements are outside tolerance limits.”

‘Smart’ Pharma

Smart technology has proliferated in the labels and packaging space. Even though it has not seen wide adoption, it certainly boasts applicability in a host of markets, with pharmaceutical labeling emerging as one of the most critical.

“Some brands have begun using RFID technology for tamper evident packaging, authentication of prefilled syringes, and tracking time and temperature during shipping,” says Avery Dennison’s Burns. “RFID is a great solution in the pharmaceutical space. Because of its unique identification and tracking capability, manufacturers are able to verify that authentic products leave their facility and reach the consumer safely.”

Smart technology might utilize specialty inks and security product combinations like taggants, charms, color shifting, photo-chromatics and thermal-chromatics to RFID and blockchain.

“Smart technology is getting smarter all the time and is being incorporated into labels and packaging with security printing features, such as overt, covert and tamper evidence, to name just a few,” explains Lux Global Label’s Archambeault.

Lux Global Label also sees the potential for augmented reality to penetrate this space. This could simplify the accessibility of information.

“The pharmaceutical industry has always been very serious concerning track and trace and the authentication of products,” explains UPM Raflatac’s Sillanpää. “New regulations, such as the EU’s Falsified Medicines Directive, mandate a unique serial number for authentication and a tamper evident device to guarantee package integrity. UPM Raflatac has developed several solutions to comply with these requirements, and additional levels of security features can be added in order to further enhance brand protection and authentication.”